Custom Metal Fabrication Services for All Your Needs

By:Admin

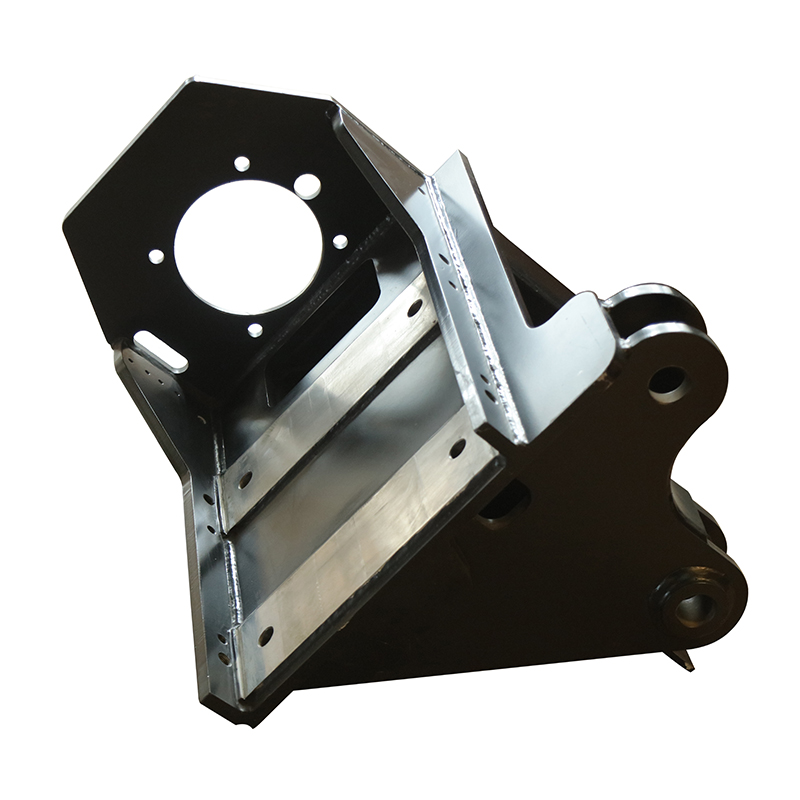

Specializing in a wide range of fabrication services, including laser cutting, welding, and metal forming, the company has the expertise and equipment to handle projects of all sizes and complexities. Their state-of-the-art facility is equipped with the latest technology and machinery, allowing them to deliver high-quality products with fast turnaround times.

The expansion of their services comes as a response to the increasing demand for custom metal fabrication solutions in various industries, including construction, automotive, and aerospace. With their extensive experience and expertise, All Metal Fabrication Services is well-positioned to meet the needs of their clients and provide solutions that meet the highest standards of quality and precision.

“Our goal is to provide our clients with the best metal fabrication solutions that meet their specific needs and requirements,” said a spokesperson for the company. “We are constantly expanding our capabilities and investing in the latest technology to ensure that we can deliver the highest quality products and services to our clients.”

In addition to their fabrication services, All Metal Fabrication Services also offers design and engineering support to help their clients bring their ideas to life. With a team of experienced engineers and designers, the company can assist with product development, prototyping, and custom fabrication projects, providing a complete solution from concept to production.

The company’s commitment to quality and customer satisfaction has earned them a reputation as a reliable and trusted partner in the metal fabrication industry. By expanding their services, they aim to further solidify their position as a leading provider of custom metal fabrication solutions, offering a one-stop shop for all metal fabrication needs.

With their expanded services, All Metal Fabrication Services is well-equipped to take on a wide range of projects, from small-scale prototypes to large-scale production runs. Their comprehensive capabilities and commitment to excellence make them a go-to choice for businesses looking for reliable and high-quality metal fabrication solutions.

For businesses in need of custom metal fabrication solutions, All Metal Fabrication Services provides a one-stop shop for all their needs. With their extensive experience, state-of-the-art facility, and commitment to quality, the company is well-positioned to meet the growing demands of the metal fabrication industry and provide comprehensive solutions for businesses across various sectors.

As they continue to expand and enhance their capabilities, All Metal Fabrication Services aims to remain at the forefront of the metal fabrication industry, providing innovative and reliable solutions that meet the evolving needs of their clients. Their dedication to quality and customer satisfaction sets them apart as a leading provider of custom metal fabrication services, capable of delivering the highest standards of excellence in every project they undertake.

For businesses looking for a trusted partner in the metal fabrication industry, All Metal Fabrication Services offers the expertise, experience, and capabilities needed to bring their projects to life. With their expanded services and commitment to excellence, the company is well-equipped to meet the growing demands of the industry and provide comprehensive solutions for businesses of all sizes.

Company News & Blog

Top 5 Custom Metal Fabrication Services to Enhance Your Business

Custom Metal Fabrication Services has been providing top-quality metal fabrication services for over a decade. The company has carved a niche for itself in the industry thanks to its commitment to producing the highest-quality products for its clients, while staying up-to-date with the latest technologies and techniques.The company offers a wide range of custom metal fabrication services to businesses across various industries, including aerospace, automotive, food and beverage, and more. The team comprises highly-skilled and experienced fabricators that are passionate about delivering exceptional results."We are proud to offer our clients a wide range of custom metal fabrication services, each tailored to meet their specific needs," said a company representative. "We are committed to ensuring that our clients get the best possible results, and we are relentless in our pursuit of excellence."Custom Metal Fabrication Services utilizes the latest technologies and materials to produce products that meet the highest-quality standards. They specialize in working with a variety of materials, including carbon steel, aluminum, stainless steel, and more.The company offers a range of services that includes designing, prototyping, manufacturing, finishing, and installation. They work closely with their clients throughout the entire process, ensuring that their unique needs are met and that their expectations are exceeded.At Custom Metal Fabrication Services, quality is of utmost importance. The company has a comprehensive quality control process in place, which ensures that every product that leaves their facility meets the required quality standards. Every project is carefully monitored and tested to ensure that it meets the client's specific requirements.The company's commitment to quality has earned them a reputation as a trusted provider of custom metal fabrication services. Clients can always count on them to deliver exceptional results on time and within budget.In addition to providing high-quality metal fabrication services, Custom Metal Fabrication Services is also committed to providing exceptional customer service. Their team is always available to assist clients throughout the entire process, from the initial consultation to the final installation."We understand that our clients have unique needs, and we are always willing to go above and beyond to ensure that those needs are met," said the company representative. "Our team is passionate about what we do, and we are committed to delivering outstanding results and exceptional customer service, every time."Custom Metal Fabrication Services has invested heavily in the latest technologies and equipment to ensure that they stay ahead of the curve in the metal fabrication industry. They are constantly exploring new ways to improve their processes and techniques to deliver the best possible results for their clients.Whether it's a small or large project, Custom Metal Fabrication Services is equipped to handle it. They have the resources, skills, and experience necessary to take on any project, from simple designs to complex custom fabrications.In conclusion, Custom Metal Fabrication Services is a premier provider of custom metal fabrication services. Their commitment to quality, exceptional customer service, and staying up-to-date with the latest technologies and techniques has earned them a reputation as a trusted provider in the industry. Businesses looking for top-quality metal fabrication services can count on Custom Metal Fabrication Services to deliver the results they need.

Unlock the Potential of Cnc Metal Cutting for Enhanced Precision and Efficiency

CNC Metal Cutting Technology: Redefining Precision and EfficiencyIn today's fast-paced manufacturing industry, precision, speed, and efficiency are essential components for businesses to stay ahead of the curve. This is where CNC Metal Cutting technology plays a critical role. With its advanced features and capabilities, CNC Metal Cutting technology is redefining the way manufacturers approach metal cutting processes.CNC Metal Cutting technology uses a series of computer numerical controls to control machines that cut, shape, and form metal materials. The technology offers numerous benefits, such as increased efficiency, cost-effectiveness, and accuracy. With CNC Metal Cutting, manufacturers can get faster production rates and consistent, high-quality results.One leading company in the CNC Metal Cutting industry is [brand name removed]. This company has been providing innovative solutions to the metal cutting market since its inception. The company offers a wide range of CNC Metal Cutting machines, including lasers, plasma cutters, waterjets, and more.The company's mission is to help businesses increase their productivity and profit margins by providing the highest quality CNC Metal Cutting machines. The company has a team of experienced engineers who use the latest technology and manufacturing techniques to create cutting-edge CNC Metal Cutting machines that are both reliable and effective.One machine that stands out from [brand name removed]'s line of CNC Metal Cutting machines is their 5-axis waterjet. The machine combines the benefits of waterjet cutting with the flexibility of 5-axis machining, making it ideal for a wide variety of applications. The 5-axis waterjet is capable of cutting complex shapes and contours with precision and accuracy, and can even cut materials up to 8 inches thick.Another standout feature of [brand name removed]'s CNC Metal Cutting machines is their user-friendly software. The company's machines come equipped with intuitive software that makes programming and operating the machines simple and straightforward. This means that even novice operators can use the machines to produce high-quality results.In addition to their top-of-the-line CNC Metal Cutting machines, [brand name removed] also offers training and support to their customers. The company's team of experts can assist businesses with everything from machine installation and setup to ongoing maintenance and repairs. This ensures that customers get the most out of their CNC Metal Cutting machines and can continue to operate at peak efficiency.Thanks to companies like [brand name removed], CNC Metal Cutting technology is helping businesses increase their productivity and profitability like never before. Whether you're in the aerospace, automotive, or construction industry, CNC Metal Cutting technology has something to offer. With its speed, precision, and efficiency, CNC Metal Cutting is redefining the metal cutting industry, and [brand name removed] is leading the way.

Discover the Latest Trends in Welding and Metal Fabrication

Title: Advancements in Welding and Metal Fabrication Pioneered by Industry LeaderIntroduction [Company Introduction: Remove brand name][Company Name], a renowned leader in the welding and metal fabrication industry, has consistently set new benchmarks through its innovative solutions and cutting-edge technologies. With a firm dedication towards quality and customer satisfaction, [Company Name] has revolutionized the sector and helped shape modern-day welding and metal fabrication practices. Through its unwavering commitment to excellence, it continues to drive advancements that redefine the industry's landscape.Body:1. History of Welding and Metal Fabrication:Welding and metal fabrication have been integral to human civilization for centuries. From ancient blacksmiths shaping metal to modern-day industries constructing intricate structures, the art of welding and metal fabrication has undergone remarkable transformations. Over time, various techniques and equipment have evolved, allowing for stronger, more durable, and complex welds.2. The Role of [Company Name] in Advancing the Industry:[Company Name] has played a pivotal role in propelling the welding and metal fabrication industry forward through its relentless pursuit of innovation and excellence. By investing in research and development, [Company Name] has introduced groundbreaking techniques and technologies that have redefined the industry's capabilities.3. Cutting-Edge Welding and Metal Fabrication Technologies:[Company Name] has consistently pioneered modern welding and metal fabrication technologies, ensuring enhanced efficiency and precision in various applications. Some notable advancements introduced by [Company Name] include: a. Laser Welding: [Company Name]'s revolutionary laser welding technology enables precise and high-speed welding, minimizing deformation and increasing productivity. The precise control offered by this technique ensures superior quality welds in various materials. b. Robotic Welding: By incorporating robotic welding systems, [Company Name] has revolutionized productivity and accuracy in metal fabrication. These systems offer a level of consistency and repeatability that human operators find hard to match, resulting in impeccable weld quality and increased output. c. CNC Plasma Cutting: [Company Name]'s CNC plasma cutting technology enables precise and efficient metal cutting, ensuring faster turnaround times and reduced material waste. This technology enables intricate designs to be translated flawlessly, expanding the possibilities for creative metal fabrication.4. Advancements in Materials and Metallurgy:[Company Name] has also focused on advancements in materials and metallurgy to cater to evolving industry needs. By harnessing innovative alloys and metals, [Company Name] has expanded the range of possible welding and fabrication applications. This includes developing high-strength materials suitable for demanding environments, as well as alloys specifically tailored for lightweight structures.5. Commitment to Safety and Sustainability:[Company Name] places great emphasis on safety and sustainability in welding and metal fabrication practices. It actively promotes the use of environmentally friendly processes, such as minimization of waste and pollution, as well as the adoption of safe welding procedures. By prioritizing sustainability, [Company Name] ensures a cleaner and greener future for the industry.Conclusion:As a frontrunner in the welding and metal fabrication industry, [Company Name] has consistently pushed the boundaries of what is possible. Through its relentless dedication to innovation, it has redefined the sector with groundbreaking technologies, materials, and safety practices. By setting new benchmarks, [Company Name] continues to shape the future of welding and metal fabrication, ensuring a more efficient, sustainable, and advanced industry for years to come.

How to Weld Stainless Steel Exhaust: Step-by-Step Guide for Long-lasting Results

Welding Stainless Steel Exhaust: Paving the Way for Efficient Vehicle PerformanceIntroduction:In today's automotive industry, the quest for efficiency, performance, and durability has led manufacturers to explore various technologies and materials. One such innovation that has made waves in the industry is the welding of stainless steel exhaust systems. By combining the strength and durability of stainless steel with the precision of welding techniques, businesses are now delivering exhaust systems that are not only resistant to corrosion but also contribute to improved vehicle performance. In this article, we will delve into the process of welding stainless steel exhausts and explore how it has revolutionized the automotive industry.Welding Stainless Steel Exhaust Systems:Stainless steel, owing to its superior strength, corrosion resistance, and thermal stability, has become the material of choice for exhaust systems in modern vehicles. However, the challenge lies in joining the various components of an exhaust system effectively. Traditional joining methods, such as clamping or bolting, often result in gaps or leaks, compromising the efficiency and performance of the system. Welding, on the other hand, offers a seamless solution for combining these components into a single, solid unit.The process of welding stainless steel exhaust systems involves several steps. First, the components of the exhaust system are meticulously cleaned to remove any dirt or debris that could affect the overall weld quality. Next, the joints are carefully aligned and clamped into place to ensure precise alignment during the welding process. With the use of advanced welding techniques such as Tungsten Inert Gas (TIG), Metal Inert Gas (MIG), or even laser welding, the components are then permanently fused together.The Benefits:Welding stainless steel exhaust systems offer numerous benefits that have sparked the interest of both manufacturers and automotive enthusiasts alike. The most notable advantage is the enhanced performance and durability it provides. By eliminating gaps and leaks, welded exhausts enable smoother airflow, reducing backpressure and increasing engine power. This improved airflow not only enhances performance but also results in better fuel efficiency.Furthermore, stainless steel's resistance to corrosion ensures that the exhaust system remains intact even under harsh weather conditions and exposure to road salt. This longevity contributes to cost savings for vehicle owners and reduces the environmental impact by minimizing the need for frequent replacements.Brand Name: (Brand Name) Excels in Stainless Steel Exhaust Welding:One prominent industry player that has carved a niche for itself in the field of stainless steel exhaust welding is (Remove Brand Name). With a reputation for delivering high-quality exhaust systems, the company has become synonymous with durability, precision, and innovation.(Company Name) employs state-of-the-art welding techniques and tools, backed by a team of highly skilled welders. The company's commitment to excellence is reflected in its strict quality control measures, ensuring that each exhaust system meets or exceeds industry standards. Additionally, (Company Name) continuously invests in research and development, staying ahead of the curve with advancements in welding technology and materials.The Future of Stainless Steel Exhaust Welding:As the automotive industry continues to evolve, so does the demand for advanced exhaust systems that improve vehicle performance and efficiency. Welding stainless steel exhausts has opened new possibilities for businesses and consumers alike. By harnessing the strengths of stainless steel and welding techniques, manufacturers can create exhaust systems that not only withstand the test of time but also enhance the overall driving experience.In conclusion, welding stainless steel exhaust systems has revolutionized the automotive industry. With its numerous benefits, including enhanced performance, durability, and resistance to corrosion, it is no wonder that this technology is gaining popularity. (Brand Name) is leading the charge in this field, delivering exhaust systems that set new benchmarks for quality and innovation. As we look to the future, the welding of stainless steel exhausts will undoubtedly continue to pave the way for more efficient and powerful vehicles.

Expert Laser Cutting and Bending Services for Precise Results

Laser Cutting and Bending Services Foster Innovation and Growth in Manufacturing IndustryAs the manufacturing industry continues to advance and innovate, the need for efficient and precise laser cutting and bending services becomes increasingly significant. These technologies have revolutionized the manufacturing process by allowing for faster, more accurate parts production and customization. With the latest laser cutting and bending technologies, manufacturers are able to create complex designs and shapes that were previously impossible, ushering in a new era of creativity and efficiency in manufacturing.One company at the forefront of this technological revolution is [company name], a leading provider of laser cutting and bending services. With state-of-the-art equipment and experienced staff, the company has established itself as a reliable and efficient partner for manufacturers in a wide range of industries.Laser cutting is a non-contact process that uses a high-powered laser to cut through various materials, including metals, plastics, and composites. This method produces clean and precise cuts, with minimal waste and distortion. Laser cutting is ideal for creating intricate designs and shapes, making it a popular choice for industries such as aerospace, automotive, and electronics.One of the most significant advantages of laser cutting is its ability to create complex designs with high precision. This allows manufacturers to create parts with tight tolerances, resulting in a more efficient and reliable final product. In addition, laser cutting is much faster than traditional cutting methods, reducing production times and increasing output.Bending is another critical process in manufacturing, and it has also benefited greatly from technological advancements. The latest bending machines use computer-controlled systems to accurately bend and shape metal parts. This technology allows for precise and repeatable bends, with minimal setup time, reducing wastage and material costs.The combination of laser cutting and bending has revolutionized the manufacturing industry, making it possible to produce parts and components with greater accuracy and efficiency than ever before. Manufacturers are now able to create complex shapes and designs, all while keeping production times and costs low.[company name] offers a wide range of laser cutting and bending services to meet the unique needs of their customers. The company has invested heavily in the latest technology to ensure that they can offer the most accurate and efficient services possible. With their advanced equipment and experienced staff, they are able to handle projects of all sizes and complexities.In addition to their laser cutting and bending services, [company name] offers a range of value-added services, including design consultation, prototype development, and assembly. This allows their customers to enjoy a full range of services, from initial product development to final assembly and delivery.The company's commitment to quality and customer satisfaction has earned them a reputation as a reliable and innovative partner for manufacturers in all industries. They work closely with their clients to ensure that their needs are met and that the final product meets the highest standards of quality.In conclusion, laser cutting and bending services are essential for modern-day manufacturing, and companies like [company name] play a critical role in meeting the growing demand for these services. With their advanced technology and innovative solutions, they are helping manufacturers to innovate and grow, creating products that are more efficient, reliable, and affordable than ever before.

Affordable Metal Cutting Laser - Latest News on Budget-Friendly Options

Title: Pioneering the Metal Cutting Industry: Revolutionary Affordable Laser Technology Disrupts Market NormsIntroduction:In an industry known for its costly equipment and extensive manual labor, a groundbreaking development is set to revolutionize metal cutting processes. A new entrant, hereinafter referred to as the "Company," has launched the market's most affordable and efficient metal cutting laser, poised to transform manufacturing operations globally. This article discusses the key features and benefits of the Cheapest Metal Cutting Laser and highlights the implications of this disruptive innovation.Disrupting Industry Norms:Traditionally, metal cutting operations have demanded substantial financial investments, making them prohibitive for small and medium-sized enterprises. However, the Company's commitment to advancing technology and affordability has revolutionized the market. The Cheapest Metal Cutting Laser disrupts industry norms by offering a cost-effective solution without compromising on efficiency or quality.Unleashing Laser Technology's Potential:The market-leading metal cutting laser represents a significant leap in laser technology, harnessing its potential and delivering exceptional results. Laser cutting processes have been highly valued for their precision and speed, streamlining manufacturing operations across various industries. The Company's innovation not only significantly reduces costs but also ensures optimal performance, making laser cutting accessible to businesses of all sizes.Key Features and Benefits:1. Affordability:The Cheapest Metal Cutting Laser is priced substantially lower than its competitors without compromising on quality or performance. This affordability allows businesses to invest in laser technology, increasing their productivity and expanding their capabilities.2. Enhanced Precision:Advanced laser technology ensures exceptional precision levels, resulting in high-quality, accurate cuts. This precision reduces material wastage, thereby enhancing cost-effectiveness and supporting sustainable manufacturing practices.3. Rapid Cutting Speeds:The Cheapest Metal Cutting Laser boasts impressive cutting speeds, dramatically reducing production time. Shorter processing times translate to increased efficiency and quicker turnaround, enabling businesses to meet growing customer demands while potentially expanding their client base.4. Versatility:With its ability to cut through various metals, including steel, aluminum, copper, and alloys, this cutting-edge technology caters to a wide range of industrial applications. From automotive parts manufacturing to intricate jewelry design, the Cheapest Metal Cutting Laser empowers businesses to explore new opportunities.5. Minimal Downtime:Designed with durability and reliability in mind, the laser tool minimizes downtime due to maintenance and repairs. This results in uninterrupted operations, reducing losses accrued from production halts and maximizing overall productivity.Implications for the Metal Cutting Industry:The introduction of this affordable metal cutting laser marks a pivotal moment in the industry. The accessibility of laser technology to a more extensive range of businesses is expected to yield several significant implications:1. Democratizing Manufacturing:The Cheapest Metal Cutting Laser democratizes the manufacturing industry by bringing laser-cutting capabilities to small and medium-sized enterprises. This broadened access fosters competition, drives innovation, and stimulates overall industry growth.2. Job Creation:As businesses adopt laser technology, there is potential for increased job creation within the metal cutting sector. The integration of advanced machinery necessitates skilled technicians, strengthening the labor market and promoting economic development.3. Sustainability:By minimizing material wastage and optimizing production processes, the Cheapest Metal Cutting Laser contributes to sustainable manufacturing practices. Efficiency gains and reduced energy consumption support eco-friendly policies, aligning industry practices with global demands for environmental responsibility.Conclusion:In this era of technological advancements, the Company has emerged as a game-changer in metal cutting. The introduction of the Cheapest Metal Cutting Laser is set to transform the industry by making laser technology more accessible, significantly reducing costs, and maintaining high precision levels. As more businesses embrace this revolutionary innovation, these affordable and efficient metal cutting lasers have the potential to shape the future of manufacturing, empowering businesses of all sizes to thrive in a highly competitive market.

Tips for Welding Stainless Steel for a Restaurant Steamer Tank Exposed to Heat

Welding stainless steel can be a challenging task, especially when it comes to repairing equipment that is constantly exposed to heat, such as a steamer tank in a restaurant. If you have been struggling to fix your stainless steel steamer tank and are getting frustrated with recurring leaks, it might be time to reconsider your repair techniques.One common mistake that people make when attempting to repair stainless steel is using adhesives like JB Weld. While JB Weld is known for its strength and versatility, it is not the ideal solution for repairing stainless steel. Adhesives like JB Weld lack the durability and temperature resistance required for withstanding the extreme conditions that stainless steel equipment in a restaurant setting endures.To effectively repair your stainless steel steamer tank, you need to consider welding as a more reliable solution. Welding provides a strong and permanent bond by joining separate metal pieces together using heat and pressure. When it comes to welding stainless steel, there are several techniques you can employ, such as TIG (Tungsten Inert Gas) welding, MIG (Metal Inert Gas) welding, and spot welding. However, TIG welding is often recommended for stainless steel due to its ability to provide precise and high-quality welds.Before attempting to weld your stainless steel steamer tank, it is crucial to prepare the surface properly. Stainless steel welding requires a clean and contamination-free surface, so make sure to remove any dirt, rust, or previous failed repair attempts. You can use a grinder or sanding tools to clean the surface and ensure a smooth and consistent finish.Once the surface is prepared, it is time to start the welding process. TIG welding stainless steel involves using a tungsten electrode to create an electric arc that generates extreme heat. This heat melts the stainless steel surface, allowing the filler material to be added to create a strong weld joint. It is important to choose the appropriate filler material that matches the stainless steel grade you are working with. Additionally, it is recommended to utilize a shielding gas such as argon or helium to protect the weld area from oxidation and prevent contamination.When welding the stainless steel steamer tank, ensure that you have the proper safety equipment, such as a welding helmet, gloves, and protective clothing. Safety should always be a priority when working with welding equipment and high temperatures.In order to prevent future leaks, it is crucial to pay attention to the welding technique and ensure a solid weld. Proper cleaning and preparation of the surface, precise heat control, and correct filler material selection are key factors in achieving a successful weld. It is also important to thoroughly inspect the weld joint after completing the repair to ensure its integrity.In conclusion, when it comes to repairing a stainless steel steamer tank in a restaurant setting, relying on adhesives like JB Weld may not provide a long-lasting solution. Welding stainless steel using techniques like TIG welding is a more reliable option. By properly preparing the surface, selecting the appropriate filler material, and employing proper welding techniques, you can achieve a strong and leak-free repair. Remember to prioritize safety during the welding process and conduct thorough inspections to ensure the quality of the weld.

Fast and High-Quality Metal Sheet Laser Cutting Services for Stainless Steel and Aluminum – Request a Free Quote

Steel Laser Cutting Service: Efficient and Precise Metal CuttingLaser cutting has been becoming increasingly popular in the metal cutting industry due to its precision and efficiency. This advanced technology uses a laser beam to cut and shape metal sheets, stainless steel, and aluminum with high accuracy and speed. It offers significant advantages over traditional metal cutting methods such as sawing, shearing, and plasma cutting. In this article, we will discuss the benefits of steel laser cutting service and why you should consider this method for your next metal cutting project.Accurate and Precise CutsOne of the biggest advantages of laser cutting is its accuracy and precision. With laser technology, you can achieve a high level of precision and control over the cutting process. This precision enables you to produce intricate and complex shapes with ease, which is not possible with traditional cutting methods. Laser cutting also ensures clean and smooth edges, minimizing the need for secondary processing or finishing.Fast and EfficientLaser cutting is also known for its speed and efficiency. The laser beam can cut through metal sheets quickly, reducing the processing time required for each sheet. This efficiency is particularly beneficial for high-volume manufacturing or large-scale projects, where you need to produce a large amount of metal parts or components in a short amount of time.Reduced Material WasteLaser cutting also helps to minimize material waste. Unlike traditional cutting methods, laser cutting offers a more precise and accurate cutting method, reducing the amount of material waste. This also means that you can save money on materials and reduce your environmental footprint.VersatilityWith laser cutting technology, you can cut and shape a variety of materials, including stainless steel, aluminum, copper, brass, and more. This versatility allows you to utilize the same equipment for different metal cutting projects, making it easier to streamline your manufacturing processes and reduce costs.Customizable and FlexibleLaser cutting is a highly customizable and flexible process. You can create custom designs and shapes to meet your specific requirements. Whether you need components for industrial machinery, decorative metal art, or architectural elements, laser cutting can deliver the exact shapes and sizes you need.ConclusionOverall, steel laser cutting service is an efficient and precise method for cutting and shaping metal sheets. With advanced laser technology, you can achieve accuracy, speed, and versatility in metal cutting and manufacturing processes. Whether you’re working on a large-scale project or a custom design, laser cutting can help you meet your metal cutting needs while saving time and money. If you’re interested in utilizing our laser cutting services, feel free to contact us for a free quote.

Discover the Best Techniques for Welding Stainless Steel to Stainless Steel

Welding Stainless To Stainless: A Seamless Connection for Durable Strength[Placeholder for brand name removal] Industries, a leading manufacturer of welding equipment and solutions, continues to push the boundaries of innovation in the welding industry. With a strong commitment to excellence and customer satisfaction, [Placeholder for brand name removal] has introduced its latest welding technology, specifically designed for welding stainless steel to stainless steel. This cutting-edge solution promises a seamless connection, providing unparalleled strength and durability.As stainless steel has become a popular choice of material in various industries, the need for efficient and reliable welding techniques has grown significantly. Welding stainless steel to stainless steel requires precision and expertise to ensure a strong bond that can withstand the test of time. This is where [Placeholder for brand name removal] Industries steps in, offering a revolutionary solution that simplifies the welding process while delivering impeccable results.The key to [Placeholder for brand name removal]'s success lies in its advanced welding technology, specifically designed to overcome the challenges associated with welding stainless steel. This innovative technology not only guarantees a strong and seamless connection but also ensures that the final weld is resistant to corrosion, a common concern when working with stainless steel.One of the standout features of this welding solution is its versatility. [Placeholder for brand name removal] Industries has developed a range of welding equipment suitable for various applications, catering to the diverse needs of industries such as construction, automotive, aerospace, and more. Whether it's joining thin sheets of stainless steel or fabricating complex structures, [Placeholder for brand name removal] provides tailored solutions to meet every requirement.The welding process itself is highly efficient, allowing for faster completion times and increased productivity. Thanks to [Placeholder for brand name removal]'s state-of-the-art technology, welders can now achieve high-quality results in a fraction of the time typically required for stainless steel welding. This not only saves valuable time but also reduces overall costs, making it an attractive solution for businesses seeking to streamline their operations.Furthermore, [Placeholder for brand name removal] Industries ensures that its welding equipment is user-friendly, even for welders with limited experience. The machines are equipped with intuitive interfaces and advanced controls, making the welding process more accessible and less prone to errors. This user-centric approach reflects [Placeholder for brand name removal]'s commitment to empowering welders and enhancing their capabilities.But it doesn't end there. [Placeholder for brand name removal]'s dedication to customer satisfaction extends beyond its innovative products. The company provides comprehensive technical support and training to its customers, ensuring seamless integration and maximum efficiency. With a team of knowledgeable experts at their disposal, customers can rely on [Placeholder for brand name removal] for guidance and assistance at every step of their welding journey.In conclusion, [Placeholder for brand name removal] Industries has revolutionized the welding industry with its groundbreaking technology for welding stainless steel to stainless steel. By combining precision, durability, and user-friendliness, [Placeholder for brand name removal] has introduced a solution that simplifies the welding process while delivering exceptional results. As businesses across different industries continue to rely on stainless steel for their projects, [Placeholder for brand name removal] remains at the forefront of innovation, providing an indispensable tool to ensure strong and durable connections that stand the test of time.