Expert Metal Bending Services for Custom Projects

By:Admin

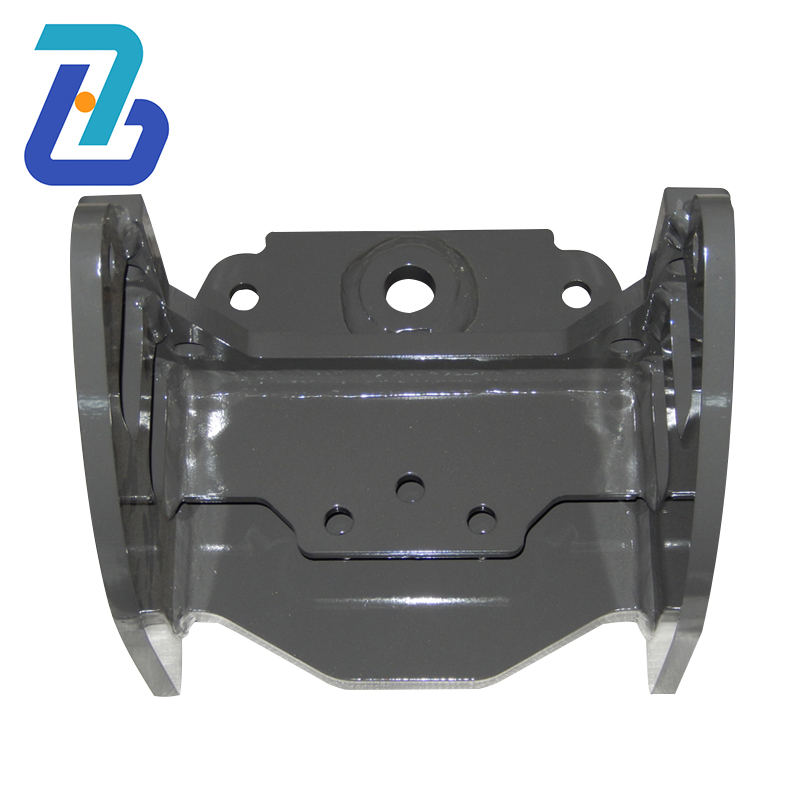

Custom Metal Bending offers a wide range of metal bending capabilities, including tube bending, pipe bending, and structural bending. Their state-of-the-art facility is equipped with the latest CNC bending machines and tools to ensure precision and accuracy in every project. From simple bends to complex shapes, the team at Custom Metal Bending has the expertise to deliver high-quality results for their clients.

In addition to metal bending, Custom Metal Bending also provides a variety of fabrication services such as welding, cutting, and assembly. Their team of skilled craftsmen and engineers work closely with clients to understand their unique requirements and provide tailored solutions to meet their specific needs. Whether it's a prototype or a large-scale production run, Custom Metal Bending has the capabilities to handle projects of any size and complexity.

One of the key differentiators of Custom Metal Bending is their commitment to continuous improvement and investment in technology. The company regularly invests in the latest machinery and software to stay ahead of the curve and provide their clients with the best possible solutions. This dedication to innovation has allowed Custom Metal Bending to expand their capabilities and take on increasingly challenging projects with confidence.

Custom Metal Bending's dedication to quality and customer satisfaction is also reflected in their ISO 9001 certification. This internationally recognized standard for quality management ensures that the company adheres to rigorous quality control measures and consistently delivers products and services that meet or exceed customer expectations. With a focus on continuous improvement and customer feedback, Custom Metal Bending is continuously enhancing their processes and services to better serve their clients.

The company's commitment to sustainability is another important aspect of their operations. Custom Metal Bending is committed to minimizing their environmental impact through responsible waste management and energy-efficient practices. They strive to source materials from suppliers with sustainable and ethical practices, and also work with clients to develop eco-friendly solutions whenever possible.

As Custom Metal Bending looks towards the future, they remain committed to staying at the forefront of the industry by embracing new technologies and expanding their capabilities. With a strong track record of delivering high-quality results and a dedicated team of professionals, the company is well-positioned to continue serving the needs of their clients and the industry as a whole.

"We are proud of our reputation for excellence and our ability to deliver custom metal bending solutions that meet the unique needs of our clients," says [spokesperson], [job title] at Custom Metal Bending. "We are dedicated to maintaining the highest standards of quality and customer satisfaction, and look forward to continuing to serve our clients with innovative and reliable solutions."

Whether it's a simple bend or a complex fabrication project, Custom Metal Bending has the expertise and capabilities to deliver exceptional results. With a strong commitment to quality, innovation, and customer satisfaction, the company continues to be a trusted partner for businesses seeking custom metal bending and fabrication services.

Company News & Blog

Highly Efficient 3 Axis CNC Vertical Machining Center Unveiled in China's Manufacturing Industry

China's 3 Axis CNC Vertical Machining Center has taken the manufacturing industry by storm. This specialized machine is designed to be used by manufacturers who want to deliver consistent precision and accuracy in their production processes. The technology behind this equipment is a marvel, and the manufacturers of this CNC Machining Center have refined it to near perfection.The Chinese manufacturer behind this innovative product has built a strong reputation for delivering high-quality machines that help revolutionize manufacturing processes. Their deep understanding of the industry's needs, coupled with their focus on innovative and cutting-edge technology, has seen them feature prominently in the industry's success stories.Like many of their machines, the 3 Axis CNC Vertical Machining Center is built to handle large volumes of material. It is ideal for a wide range of industries such as automotive, aerospace, medical devices, and many more, where precision and accuracy are critical.The 3 Axis CNC Vertical Machining Center is designed with the user in mind. It is easy to operate, and the user interface is intuitive, eliminating the need for specialized training. This machine is a perfect fit for users who want to optimize their process as it enables them to deliver higher quality products quickly.One of the standout features of this machine is that it can handle complex and intricate shapes and designs. With the 3-axis configuration, this machining center allows for multi-dimensional cutting, which provides the user with a wide range of processing capabilities.Another notable feature of this machining center is the spindle speed. The spindle speed is an important aspect of machining, and the 3 Axis CNC Vertical Machining Center delivers on this. It has a high speed, and the spindle can handle a wide range of materials, including steel, copper, and aluminum. This means that manufacturers can process materials with a high degree of efficiency since they can handle varying degrees of hardness.In addition, this machine is highly versatile. Its configuration can be customized to meet specific production requirements. Whether it's a varying range of material types or shapes, the 3 Axis CNC Vertical Machining Center is a machine you can count on to deliver precision and accuracy with every cut.The Chinese manufacturer of this machine has demonstrated their commitment to delivering machines that are not only efficient, but that help customers achieve excellence in their manufacturing processes. They have invested in research and development to ensure this machine aligns with the latest technological advancements. They are always looking for ways to make their machines more efficient and more effective.Through their extensive network of authorized dealers and support mechanisms, the Chinese manufacturer ensures that customers get the support they need to optimize their processes. They offer technical support, machine maintenance, and a wide range of spare parts associated with their machines.Overall, the 3 Axis CNC Vertical Machining Center is a machine that is setting new standards in the manufacturing industry. With its high precision, versatility, and efficiency, it is no surprise that it has become a popular choice for manufacturers and businesses in various industries. The Chinese manufacturer behind this machine has proven to be a reliable partner for businesses looking to refine their processes, and with their commitment to excellence, we can expect more innovative products from them in the future.

Highly Efficient Precision Laser Cutter for Metals: Cut Steel, Aluminum, Copper, and Titanium With Ease Using Advanced Fiber Laser Technology - Mechanical Kingdom

Precision Laser Cutting: Unlocking New Possibilities with SS Laser CuttingWhen it comes to precision cutting, Ss stainless steel is one of the most challenging materials to work with. But with the rise of advanced laser cutting technology, what was once considered difficult has now become achievable with ease. One such technology is the Fy4050b Precision Laser Cutter from Feiyue Laser.The Fy4050b Precision Laser Cutter is a top-of-the-line CNC cutting machine that can handle a variety of materials, including stainless steel plates, aluminum, copper, titanium sheets, and jewelry metal. What sets this machine apart is its fixed optical path design, which provides a maintenance-free optical path and low operating cost while delivering high processing efficiency and cutting quality. Equipped with an international advanced fiber laser, the Fy4050b machine is capable of cutting through thick metal sheets with precision and accuracy, providing you with clean and smooth edges that require minimal post-processing. This makes it ideal for a range of applications, from industrial to jewelry making.The cutting head of the Fy4050b machine uses the LASERMECH optical fiber cutting head imported from the United States. It's also fitted with a capacitive sensor, which provides high sensing accuracy, sensitive response, and stable and reliable performance. This means you get a quality cut every time, regardless of the shape or size of the material.The CNC system of the Fy4050b machine is specially designed for laser cutting. It uses an imported non-contact height tracking system that's sensitive and accurate, and is not affected by the shape of the material. This helps to eliminate potential errors during the cutting process, ensuring that you get precise and clean cuts every time. Overall, the Fy4050b Precision Laser Cutter is a valuable investment for anyone looking to get into laser cutting. It's affordable, versatile, and reliable, making it a great choice for businesses and hobbyists alike. With its exceptional cutting quality and high processing efficiency, this machine is sure to unlock new possibilities in your metal cutting projects.In conclusion, choosing the right laser cutter is crucial, especially when it comes to working with tough materials like Ss stainless steel. With the Fy4050b Precision Laser Cutter from Feiyue Laser, you're assured of a quality machine that can handle all your metal cutting needs with ease, precision, and efficiency. This cutting-edge technology is transforming the metal-cutting industry, making it easier and more affordable to achieve precision cuts than ever before. So, invest in the Fy4050b Precision Laser Cutter today and take your metal cutting projects to a whole new level!

Top CNC Sheet Metal Cutting Techniques for Precision Results

CNC sheet metal cutting is a highly advanced and precise method of cutting metal sheets using computer numerical control technology. This technology allows for accurate and efficient cutting of metal sheets, making it ideal for a wide range of industries such as automotive, aerospace, construction, and manufacturing.With the increasing demand for high-quality sheet metal cutting, the need for advanced and automated cutting technologies has become imperative. This is where the innovative solutions offered by {} come into play.Established in 1998, {} has become a renowned name in the field of sheet metal cutting, thanks to its commitment to delivering cutting-edge solutions and exceptional customer service. The company's dedication to embracing the latest technological advancements has allowed it to stay ahead of the competition and consistently meet the evolving needs of its clients.{} offers a wide range of CNC sheet metal cutting services, including laser cutting, plasma cutting, and waterjet cutting. These services are tailored to meet the specific requirements of each client, ensuring that they receive the highest quality cuts with minimal material waste.The company's state-of-the-art facilities are equipped with the latest CNC machines, which are operated by highly skilled and experienced technicians. This ensures that every cut is precise, accurate, and of the highest quality.One of the key advantages of {} is its ability to handle both small-scale and large-scale projects with equal ease. Whether it's a small prototype or a mass production run, the company has the capacity and expertise to deliver exceptional results within tight deadlines.In addition to its cutting-edge technology and exceptional capabilities, {} is also committed to sustainability and environmental responsibility. The company implements eco-friendly practices in its operations, including the recycling of metal waste and the use of energy-efficient machinery.Furthermore, {} places a strong emphasis on customer satisfaction, striving to exceed client expectations in every project it undertakes. The company works closely with its clients to understand their unique requirements and provide tailored solutions that meet and exceed their expectations.The combination of cutting-edge technology, skilled workforce, commitment to sustainability, and customer-centric approach has made {} a trusted partner for companies across various industries.As the demand for high-quality sheet metal cutting continues to rise, {} remains at the forefront of the industry, constantly pushing the boundaries of what is possible with CNC sheet metal cutting technology. With its unwavering dedication to excellence, innovation, and customer satisfaction, the company is well-positioned to meet the evolving needs of its clients and maintain its leadership in the sheet metal cutting industry.

Tips for Welding Stainless Steel for a Restaurant Steamer Tank Exposed to Heat

Welding stainless steel can be a challenging task, especially when it comes to repairing equipment that is constantly exposed to heat, such as a steamer tank in a restaurant. If you have been struggling to fix your stainless steel steamer tank and are getting frustrated with recurring leaks, it might be time to reconsider your repair techniques.One common mistake that people make when attempting to repair stainless steel is using adhesives like JB Weld. While JB Weld is known for its strength and versatility, it is not the ideal solution for repairing stainless steel. Adhesives like JB Weld lack the durability and temperature resistance required for withstanding the extreme conditions that stainless steel equipment in a restaurant setting endures.To effectively repair your stainless steel steamer tank, you need to consider welding as a more reliable solution. Welding provides a strong and permanent bond by joining separate metal pieces together using heat and pressure. When it comes to welding stainless steel, there are several techniques you can employ, such as TIG (Tungsten Inert Gas) welding, MIG (Metal Inert Gas) welding, and spot welding. However, TIG welding is often recommended for stainless steel due to its ability to provide precise and high-quality welds.Before attempting to weld your stainless steel steamer tank, it is crucial to prepare the surface properly. Stainless steel welding requires a clean and contamination-free surface, so make sure to remove any dirt, rust, or previous failed repair attempts. You can use a grinder or sanding tools to clean the surface and ensure a smooth and consistent finish.Once the surface is prepared, it is time to start the welding process. TIG welding stainless steel involves using a tungsten electrode to create an electric arc that generates extreme heat. This heat melts the stainless steel surface, allowing the filler material to be added to create a strong weld joint. It is important to choose the appropriate filler material that matches the stainless steel grade you are working with. Additionally, it is recommended to utilize a shielding gas such as argon or helium to protect the weld area from oxidation and prevent contamination.When welding the stainless steel steamer tank, ensure that you have the proper safety equipment, such as a welding helmet, gloves, and protective clothing. Safety should always be a priority when working with welding equipment and high temperatures.In order to prevent future leaks, it is crucial to pay attention to the welding technique and ensure a solid weld. Proper cleaning and preparation of the surface, precise heat control, and correct filler material selection are key factors in achieving a successful weld. It is also important to thoroughly inspect the weld joint after completing the repair to ensure its integrity.In conclusion, when it comes to repairing a stainless steel steamer tank in a restaurant setting, relying on adhesives like JB Weld may not provide a long-lasting solution. Welding stainless steel using techniques like TIG welding is a more reliable option. By properly preparing the surface, selecting the appropriate filler material, and employing proper welding techniques, you can achieve a strong and leak-free repair. Remember to prioritize safety during the welding process and conduct thorough inspections to ensure the quality of the weld.

Suppliers of Welders, Metal Fabrications, and Welding Tools with Customer Reviews and Detailed Information

Custom Metal Fabrication Services: A Closer Look at Bend Fabrication's Expertise

Bend Fabrication is a leading fabricator of high-quality metal products, with a specialization in precision bending and forming. With over 20 years of experience in the industry, their team of expert craftsmen and technicians is dedicated to delivering top-notch solutions for a wide range of applications, from automotive and aerospace to industrial and architectural.Their state-of-the-art facility is equipped with the latest machinery and technology to ensure that they can meet the most demanding requirements of their clients. From prototype to production, Bend Fabrication has the capabilities and expertise to handle projects of any scale and complexity, with a strong commitment to delivering on time and within budget.Their unwavering dedication to quality and customer satisfaction has earned them a solid reputation in the industry, with a long list of satisfied clients who trust them to deliver precision-crafted products that meet their exact specifications.Bend Fabrication is proud to announce that they have recently expanded their capabilities with the addition of a new CNC bending machine. This cutting-edge equipment allows them to offer even greater precision and efficiency in their bending and forming processes, further solidifying their position as a leader in the industry.The new CNC bending machine features state-of-the-art technology that enables Bend Fabrication to produce complex and intricate bends with unparalleled accuracy. This means that they can now offer their clients an even wider range of options for their metal fabrication needs, while maintaining the same high standards of quality and precision that they are known for."We are thrilled to introduce this new CNC bending machine to our facility," said the CEO of Bend Fabrication. "This investment reflects our ongoing commitment to providing our clients with the best possible solutions for their metal fabrication needs. With this new equipment, we can take on even more complex projects and deliver results that exceed our clients' expectations."In addition to the new CNC bending machine, Bend Fabrication has also made significant investments in their workforce and processes to ensure that they remain at the forefront of the industry. Their team of expert craftsmen and technicians undergo regular training and development to stay ahead of the latest advancements in metal fabrication, while their facility is constantly updated to incorporate the most advanced technology available.As a result, Bend Fabrication continues to be the go-to choice for clients who demand nothing but the best for their metal fabrication needs. Whether it's a one-off prototype or a large-scale production run, they have the expertise, technology, and dedication to deliver exceptional results every time."We take great pride in our ability to meet and exceed the needs of our clients," added the CEO. "With our expanded capabilities and unwavering commitment to quality, we are well-positioned to take on new challenges and continue to provide innovative solutions for our clients in the years to come."As they continue to grow and expand their offerings, Bend Fabrication remains dedicated to upholding their core values of quality, precision, and customer satisfaction. With their new CNC bending machine and a talented team of craftsmen and technicians, they are well-equipped to tackle the most demanding projects and deliver results that truly stand out in the industry.In conclusion, Bend Fabrication is a company that is dedicated to providing top-notch metal fabrication solutions for a wide range of applications. With their recent expansion and the addition of a new CNC bending machine, they are poised to continue their track record of delivering exceptional results for their clients. Whether it's precision bending and forming or any other metal fabrication needs, Bend Fabrication has the expertise, technology, and commitment to excellence to get the job done.

Top Benefits of Laser Cutting for Precision Fabrication

Laser Cutting Technology Revolutionizes Manufacturing IndustryIn today’s ever-evolving world of technology, the manufacturing industry has seen remarkable advancements that have revolutionized production processes. One of the most significant technological innovations to impact manufacturing is the introduction of laser cutting technology. This cutting-edge process has catapulted the industry into a new era of precision and efficiency, and one company at the forefront of this revolution is {}.Established in 1990, {} has been a pioneer in the field of manufacturing and production solutions. The company’s commitment to innovation and quality has positioned them as a leader in the industry, and their latest investment in laser cutting technology further solidifies their reputation as a forward-thinking organization.Laser cutting is a manufacturing process that uses a high-powered laser beam to precisely cut through materials such as metal, plastic, wood, rubber, and more. This technology offers several advantages over traditional cutting methods, including enhanced precision, reduced waste, and higher production speeds. By harnessing the power of laser cutting, {} has been able to elevate their manufacturing capabilities to new heights.One of the key benefits of laser cutting is its ability to produce intricate and complex designs with unparalleled accuracy. This level of precision has enabled {} to take on a wide range of projects that were previously deemed unattainable. Whether it’s creating intricate metal components for the aerospace industry or crafting custom-designed parts for the automotive sector, {} has leveraged laser cutting technology to produce exceptional results for their clients.In addition to precision, laser cutting technology has also proven to be highly efficient in terms of production. The speed and consistency at which the laser cuts through materials allows {} to streamline their manufacturing processes, reducing lead times and increasing overall productivity. This enhanced efficiency has not only benefited {} in terms of cost savings and faster project turnaround times but has also allowed them to meet the growing demands of their clientele.Furthermore, laser cutting has significantly minimized material waste in {}’s production facilities. Traditional cutting methods often result in a considerable amount of wasted material due to the imprecise nature of the process. With laser cutting, {} has been able to optimize material usage, leading to reduced waste and lower production costs. This dedication to sustainability aligns with {}’s commitment to environmentally-friendly manufacturing practices.As a testament to their investment in laser cutting technology, {} has expanded their service offerings to include a diverse range of materials and thicknesses. Whether it’s cutting thin sheets of metal with intricate patterns or tackling thicker materials for industrial applications, {} has demonstrated their versatility and expertise in adapting to the demands of the market.Looking ahead, {} is committed to further exploring the potential of laser cutting technology and its applications in the manufacturing industry. With ongoing investments in research and development, the company aims to push the boundaries of what is achievable with this cutting-edge technology. By continuously innovating and leveraging the latest advancements in manufacturing, {} is poised to remain a trailblazer in the industry.In conclusion, laser cutting technology has undeniably revolutionized the manufacturing industry, and {} has been at the forefront of this transformative shift. With its unparalleled precision, efficiency, and versatility, laser cutting has enabled {} to elevate their manufacturing capabilities and deliver exceptional results for their clients. As technology continues to advance, it’s clear that laser cutting will play a crucial role in shaping the future of manufacturing, and {} stands ready to lead the way.

Sheet Metal Fabrication Services for Copper Materials: What You Need to Know

Copper Sheet Metal Fabrication: A Cutting-Edge Service Provided by {Company Name}In the world of metal fabrication, copper sheet metal stands out for its unique properties and a wide range of applications, from electrical wiring and plumbing to architectural features and artistic designs. Recognizing the growing demand for high-quality copper sheet metal fabrication, {Company Name} has emerged as a leading provider of this specialized service, offering precision, expertise, and a commitment to excellence.Founded in {year}, {Company Name} has built a sterling reputation for its expertise in metal fabrication, serving a diverse clientele across industries such as construction, manufacturing, and the arts. With a state-of-the-art facility equipped with cutting-edge technology and a team of highly skilled craftsmen, {Company Name} has positioned itself as a trusted partner for clients seeking top-tier metal fabrication solutions.When it comes to copper sheet metal fabrication, precision is of the utmost importance, and {Company Name} understands this better than anyone. Through a combination of advanced machinery and meticulous handcraftsmanship, the company is able to deliver custom copper sheet metal products that meet the highest standards of quality and accuracy. Whether it's a complex architectural element or a specialized component for industrial machinery, {Company Name} has the expertise and capabilities to bring the most intricate copper sheet metal designs to life.The benefits of copper sheet metal fabrication are manifold, and {Company Name} is dedicated to unlocking its full potential for its clients. With its exceptional conductivity, corrosion resistance, and malleability, copper sheet metal offers unparalleled versatility in applications ranging from electrical components to decorative features. {Company Name} leverages these properties to create bespoke copper sheet metal solutions that align with the specific needs and aesthetic preferences of each client.Moreover, {Company Name} takes pride in its commitment to sustainability and environmental responsibility. Copper is a fully recyclable material, and the company emphasizes the use of recycled copper in its fabrication processes whenever possible. By leveraging eco-friendly practices and prioritizing the efficient use of resources, {Company Name} strives to minimize its environmental impact while delivering top-tier copper sheet metal solutions to its clients.In addition to its technical expertise, {Company Name} stands out for its client-centric approach to service. The company places a strong emphasis on collaboration, working closely with clients throughout the fabrication process to understand their vision, address their specific requirements, and ensure the seamless realization of their projects. Whether it's consulting on design concepts, providing expert guidance on material selection, or accommodating special requests, {Company Name} is dedicated to delivering a tailored and attentive experience to every client.{Company Name} takes pride in the diversity of its portfolio, having successfully executed a wide range of projects that showcase the versatility of copper sheet metal. From large-scale architectural installations to intricate artistic creations, the company's work is a testament to its technical acumen, creative flair, and unwavering commitment to excellence. With a track record of delivering exceptional results across industries and applications, {Company Name} continues to be a go-to resource for clients seeking superior copper sheet metal fabrication services.As the demand for copper sheet metal fabrication continues to grow, {Company Name} remains at the forefront of the industry, poised to meet the evolving needs of its clients with unmatched expertise and innovation. With its focus on precision, sustainability, client collaboration, and superior craftsmanship, {Company Name} is redefining the possibilities of copper sheet metal fabrication, setting new standards for quality and excellence in the field. As the company looks ahead, it is committed to further elevating its capabilities and expanding its impact, solidifying its position as a trusted leader in the world of metal fabrication.

Ultimate Guide to Plasma Cutting Thin Sheet Metal for Precision Results

Plasma Cutting Thin Sheet Metal Revolutionizes Metal Fabrication ProcessIn the world of metal fabrication, precision and efficiency are key factors that can make or break a business. With the advancement of technology, the methods for cutting and shaping thin sheet metal have evolved to meet the demands of modern industry. One such method that has revolutionized the metal fabrication process is plasma cutting.Plasma cutting is a process that uses a high-velocity jet of ionized gas (plasma) to melt and sever metal. This method is highly effective for cutting thin sheet metal, as it allows for precise and clean cuts, making it an ideal choice for various industries such as automotive, aerospace, and construction.One company that has been at the forefront of plasma cutting technology is {}. With over 30 years of experience in the metal fabrication industry, {} has established itself as a leading provider of cutting-edge solutions for cutting thin sheet metal with precision and accuracy.{} offers a range of plasma cutting systems that are designed to meet the specific needs of their customers. From small-scale operations to large industrial facilities, {} provides cutting-edge technology that delivers high-quality results.The company's plasma cutting systems are equipped with advanced features that make them stand out in the industry. With their high-speed cutting capabilities, {}'s plasma cutting systems can produce clean and precise cuts on thin sheet metal, reducing the need for secondary finishing processes. This not only saves time but also increases productivity and lowers production costs for their customers.In addition, {}'s plasma cutting systems are known for their user-friendly interface and intuitive controls, making them easy to operate for both experienced and novice users. This ensures that the cutting process is efficient and accurate, regardless of the operator's skill level.Furthermore, {}'s plasma cutting systems are built with durability and reliability in mind. These systems are designed to withstand the rigors of industrial production environments, providing consistent performance and minimal downtime for their customers.One of the key advantages of {}'s plasma cutting systems is their ability to cut a wide range of materials with precision. Whether it's stainless steel, aluminum, or titanium, {}'s plasma cutting technology can handle it all, providing versatility and flexibility for their customers' diverse fabrication needs.Another factor that sets {} apart is their commitment to customer satisfaction. The company provides comprehensive support and training for their customers, ensuring that they get the most out of their plasma cutting systems. From installation and setup to troubleshooting and maintenance, {}'s team of experts is dedicated to providing top-notch support for their customers.With the increasing demand for high-quality metal fabrication solutions, {}'s plasma cutting technology has become a game-changer for the industry. By providing precise, efficient, and reliable cutting solutions for thin sheet metal, {} is empowering businesses to elevate their fabrication capabilities and stay ahead of the competition.In conclusion, plasma cutting has significantly transformed the metal fabrication process, especially when it comes to cutting thin sheet metal. With {} at the forefront of this technology, businesses can expect to achieve superior results and increase their efficiency in metal fabrication. As the industry continues to evolve, {} remains committed to pushing the boundaries of plasma cutting technology, delivering innovative solutions that meet the ever-changing demands of the metal fabrication industry.

High-Quality Laser Die Cutting Services for Precision Cutting

Laser Die Cutting Services Revolutionizing the Manufacturing IndustryIn the era of advanced technology, the manufacturing industry continues to evolve and innovate in order to meet the demands of the market. One such innovation that has been making waves in the manufacturing world is laser die cutting services. This cutting-edge technology has revolutionized the way products are made, providing precision, efficiency, and flexibility that traditional die cutting methods simply cannot match.Laser die cutting services utilize high-powered lasers to precisely cut and engrave materials, offering a level of accuracy and intricacy that is unmatched by traditional die cutting methods. This technology has found its way into a wide range of industries, including automotive, electronics, packaging, and medical devices, among others. The ability to cut and shape materials with such precision has opened up new possibilities for manufacturing, allowing for the production of complex and intricate designs that were previously unattainable.One company that has been at the forefront of this innovation is {}. They have been providing cutting-edge laser die cutting services to a diverse range of industries, offering a level of precision and quality that is second to none. With state-of-the-art equipment and a team of skilled professionals, {} has been able to meet the unique and demanding needs of their clients, delivering exceptional results time and time again.The benefits of laser die cutting services are numerous. From intricate and precise cutting to the ability to work with a wide range of materials, including plastics, metals, and composites, this technology offers a level of versatility that traditional die cutting methods simply cannot match. In addition, laser die cutting services can significantly reduce production time and costs, as well as minimize material waste, making it a highly efficient and cost-effective option for manufacturers.Moreover, laser die cutting allows for quick and easy design changes, as there is no need for costly and time-consuming tooling adjustments. This level of flexibility is invaluable in today's fast-paced and ever-changing market, where manufacturers must constantly adapt to meet the demands of consumers.With the increasing demand for precision and efficiency in manufacturing, laser die cutting services have quickly become an essential tool for manufacturers looking to stay ahead of the competition. By offering unparalleled precision, flexibility, and efficiency, this cutting-edge technology has raised the bar for product design and manufacturing, providing a level of quality and intricacy that was once thought to be unattainable.As the manufacturing industry continues to evolve and innovate, it is clear that laser die cutting services will play a critical role in shaping the future of manufacturing. With its ability to produce intricate and precise designs with unparalleled efficiency, this technology is set to revolutionize the way products are made, setting new standards for quality and innovation in manufacturing. And with companies like {} leading the way, the future of manufacturing looks brighter than ever.