- Home

- Blog

- Highly Efficient 3 Axis CNC Vertical Machining Center Unveiled in China's Manufacturing Industry

Highly Efficient 3 Axis CNC Vertical Machining Center Unveiled in China's Manufacturing Industry

By:Admin

The Chinese manufacturer behind this innovative product has built a strong reputation for delivering high-quality machines that help revolutionize manufacturing processes. Their deep understanding of the industry's needs, coupled with their focus on innovative and cutting-edge technology, has seen them feature prominently in the industry's success stories.

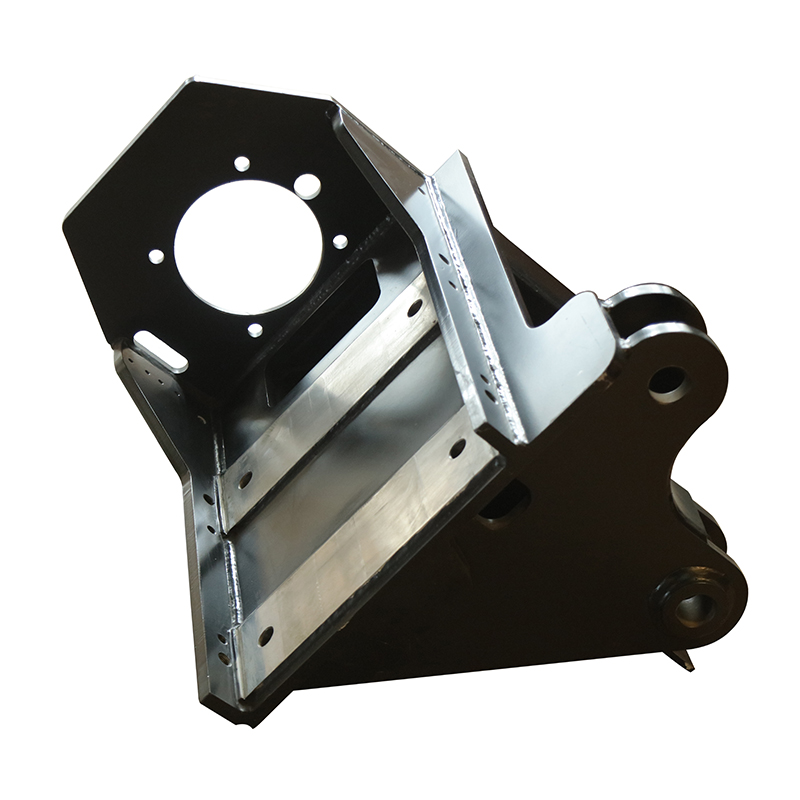

Like many of their machines, the 3 Axis CNC Vertical Machining Center is built to handle large volumes of material. It is ideal for a wide range of industries such as automotive, aerospace, medical devices, and many more, where precision and accuracy are critical.

The 3 Axis CNC Vertical Machining Center is designed with the user in mind. It is easy to operate, and the user interface is intuitive, eliminating the need for specialized training. This machine is a perfect fit for users who want to optimize their process as it enables them to deliver higher quality products quickly.

One of the standout features of this machine is that it can handle complex and intricate shapes and designs. With the 3-axis configuration, this machining center allows for multi-dimensional cutting, which provides the user with a wide range of processing capabilities.

Another notable feature of this machining center is the spindle speed. The spindle speed is an important aspect of machining, and the 3 Axis CNC Vertical Machining Center delivers on this. It has a high speed, and the spindle can handle a wide range of materials, including steel, copper, and aluminum. This means that manufacturers can process materials with a high degree of efficiency since they can handle varying degrees of hardness.

In addition, this machine is highly versatile. Its configuration can be customized to meet specific production requirements. Whether it's a varying range of material types or shapes, the 3 Axis CNC Vertical Machining Center is a machine you can count on to deliver precision and accuracy with every cut.

The Chinese manufacturer of this machine has demonstrated their commitment to delivering machines that are not only efficient, but that help customers achieve excellence in their manufacturing processes. They have invested in research and development to ensure this machine aligns with the latest technological advancements. They are always looking for ways to make their machines more efficient and more effective.

Through their extensive network of authorized dealers and support mechanisms, the Chinese manufacturer ensures that customers get the support they need to optimize their processes. They offer technical support, machine maintenance, and a wide range of spare parts associated with their machines.

Overall, the 3 Axis CNC Vertical Machining Center is a machine that is setting new standards in the manufacturing industry. With its high precision, versatility, and efficiency, it is no surprise that it has become a popular choice for manufacturers and businesses in various industries. The Chinese manufacturer behind this machine has proven to be a reliable partner for businesses looking to refine their processes, and with their commitment to excellence, we can expect more innovative products from them in the future.

Company News & Blog

How to Weld Stainless Steel Exhaust: Step-by-Step Guide for Long-lasting Results

Welding Stainless Steel Exhaust: Paving the Way for Efficient Vehicle PerformanceIntroduction:In today's automotive industry, the quest for efficiency, performance, and durability has led manufacturers to explore various technologies and materials. One such innovation that has made waves in the industry is the welding of stainless steel exhaust systems. By combining the strength and durability of stainless steel with the precision of welding techniques, businesses are now delivering exhaust systems that are not only resistant to corrosion but also contribute to improved vehicle performance. In this article, we will delve into the process of welding stainless steel exhausts and explore how it has revolutionized the automotive industry.Welding Stainless Steel Exhaust Systems:Stainless steel, owing to its superior strength, corrosion resistance, and thermal stability, has become the material of choice for exhaust systems in modern vehicles. However, the challenge lies in joining the various components of an exhaust system effectively. Traditional joining methods, such as clamping or bolting, often result in gaps or leaks, compromising the efficiency and performance of the system. Welding, on the other hand, offers a seamless solution for combining these components into a single, solid unit.The process of welding stainless steel exhaust systems involves several steps. First, the components of the exhaust system are meticulously cleaned to remove any dirt or debris that could affect the overall weld quality. Next, the joints are carefully aligned and clamped into place to ensure precise alignment during the welding process. With the use of advanced welding techniques such as Tungsten Inert Gas (TIG), Metal Inert Gas (MIG), or even laser welding, the components are then permanently fused together.The Benefits:Welding stainless steel exhaust systems offer numerous benefits that have sparked the interest of both manufacturers and automotive enthusiasts alike. The most notable advantage is the enhanced performance and durability it provides. By eliminating gaps and leaks, welded exhausts enable smoother airflow, reducing backpressure and increasing engine power. This improved airflow not only enhances performance but also results in better fuel efficiency.Furthermore, stainless steel's resistance to corrosion ensures that the exhaust system remains intact even under harsh weather conditions and exposure to road salt. This longevity contributes to cost savings for vehicle owners and reduces the environmental impact by minimizing the need for frequent replacements.Brand Name: (Brand Name) Excels in Stainless Steel Exhaust Welding:One prominent industry player that has carved a niche for itself in the field of stainless steel exhaust welding is (Remove Brand Name). With a reputation for delivering high-quality exhaust systems, the company has become synonymous with durability, precision, and innovation.(Company Name) employs state-of-the-art welding techniques and tools, backed by a team of highly skilled welders. The company's commitment to excellence is reflected in its strict quality control measures, ensuring that each exhaust system meets or exceeds industry standards. Additionally, (Company Name) continuously invests in research and development, staying ahead of the curve with advancements in welding technology and materials.The Future of Stainless Steel Exhaust Welding:As the automotive industry continues to evolve, so does the demand for advanced exhaust systems that improve vehicle performance and efficiency. Welding stainless steel exhausts has opened new possibilities for businesses and consumers alike. By harnessing the strengths of stainless steel and welding techniques, manufacturers can create exhaust systems that not only withstand the test of time but also enhance the overall driving experience.In conclusion, welding stainless steel exhaust systems has revolutionized the automotive industry. With its numerous benefits, including enhanced performance, durability, and resistance to corrosion, it is no wonder that this technology is gaining popularity. (Brand Name) is leading the charge in this field, delivering exhaust systems that set new benchmarks for quality and innovation. As we look to the future, the welding of stainless steel exhausts will undoubtedly continue to pave the way for more efficient and powerful vehicles.

Unlock the Potential of Cnc Metal Cutting for Enhanced Precision and Efficiency

CNC Metal Cutting Technology: Redefining Precision and EfficiencyIn today's fast-paced manufacturing industry, precision, speed, and efficiency are essential components for businesses to stay ahead of the curve. This is where CNC Metal Cutting technology plays a critical role. With its advanced features and capabilities, CNC Metal Cutting technology is redefining the way manufacturers approach metal cutting processes.CNC Metal Cutting technology uses a series of computer numerical controls to control machines that cut, shape, and form metal materials. The technology offers numerous benefits, such as increased efficiency, cost-effectiveness, and accuracy. With CNC Metal Cutting, manufacturers can get faster production rates and consistent, high-quality results.One leading company in the CNC Metal Cutting industry is [brand name removed]. This company has been providing innovative solutions to the metal cutting market since its inception. The company offers a wide range of CNC Metal Cutting machines, including lasers, plasma cutters, waterjets, and more.The company's mission is to help businesses increase their productivity and profit margins by providing the highest quality CNC Metal Cutting machines. The company has a team of experienced engineers who use the latest technology and manufacturing techniques to create cutting-edge CNC Metal Cutting machines that are both reliable and effective.One machine that stands out from [brand name removed]'s line of CNC Metal Cutting machines is their 5-axis waterjet. The machine combines the benefits of waterjet cutting with the flexibility of 5-axis machining, making it ideal for a wide variety of applications. The 5-axis waterjet is capable of cutting complex shapes and contours with precision and accuracy, and can even cut materials up to 8 inches thick.Another standout feature of [brand name removed]'s CNC Metal Cutting machines is their user-friendly software. The company's machines come equipped with intuitive software that makes programming and operating the machines simple and straightforward. This means that even novice operators can use the machines to produce high-quality results.In addition to their top-of-the-line CNC Metal Cutting machines, [brand name removed] also offers training and support to their customers. The company's team of experts can assist businesses with everything from machine installation and setup to ongoing maintenance and repairs. This ensures that customers get the most out of their CNC Metal Cutting machines and can continue to operate at peak efficiency.Thanks to companies like [brand name removed], CNC Metal Cutting technology is helping businesses increase their productivity and profitability like never before. Whether you're in the aerospace, automotive, or construction industry, CNC Metal Cutting technology has something to offer. With its speed, precision, and efficiency, CNC Metal Cutting is redefining the metal cutting industry, and [brand name removed] is leading the way.

Reliable Metal Forming Services Revamp Manufacturing Processes for Enhanced Efficiency

Metal Forming Services, a renowned manufacturer in the metalworking industry, continues to revolutionize the sector with its cutting-edge technology and efficient solutions. With a dedicated team of experts and state-of-the-art facilities, the company has built a strong reputation for delivering high-quality products and exemplary customer service.Metal Forming Services is committed to meeting the growing demands of various industries, including automotive, aerospace, and construction. They offer a wide range of metal forming services, such as stamping, bending, and deep drawing. Their advanced equipment and skilled technicians allow them to tackle complex projects with precision and consistency.One of Metal Forming Services' key strengths lies in their ability to customize solutions that meet individual client specifications. They understand that every project is unique and requires a tailored approach. Through close collaboration with customers, they gather detailed requirements and provide innovative solutions that fulfill their specific needs.The company's commitment to cutting-edge technology has been instrumental in their success. They continuously invest in the latest equipment, allowing them to stay at the forefront of the industry. By embracing automation and digitalization, Metal Forming Services ensures increased efficiency, reduced lead times, and enhanced product quality.Moreover, Metal Forming Services prioritizes sustainability and adopts environmentally friendly practices throughout their operations. They understand the importance of minimizing their ecological footprint and strive to make a positive impact on the environment. From employing energy-efficient machinery to recycling waste materials, they are dedicated to promoting sustainability in the metalworking industry.As a customer-centric company, Metal Forming Services places great emphasis on delivering exceptional service. They value their relationships with clients and strive to exceed expectations at every opportunity. Their knowledgeable and friendly staff are always available to address any concerns and provide prompt assistance, making the customer experience seamless and enjoyable.To ensure consistent excellence, Metal Forming Services employs a rigorous quality control process. They adhere to stringent industry standards and implement stringent quality assurance measures. With a comprehensive inspection system in place, they guarantee that every product leaving their facility meets or exceeds the highest quality benchmarks.In addition to their commitment to quality, Metal Forming Services believes in fostering a culture of safety in the workplace. They prioritize the well-being of their employees and strictly adhere to safety protocols to minimize accidents and injuries. By providing a safe and secure working environment, they promote employee satisfaction and productivity.Metal Forming Services also prides itself on its continuous commitment to research and development. They understand the importance of staying ahead of technological advancements and industry trends. Through ongoing innovation and learning, they anticipate emerging needs and deliver solutions that cater to the evolving demands of their customers.As a market leader in the metalworking industry, Metal Forming Services continues to set the benchmark for excellence. Their unwavering dedication to customer satisfaction, technological innovation, and sustainable practices ensures that they remain at the forefront of the industry. With each project they undertake, they strive to create lasting partnerships and deliver unparalleled value to their clients.In summary, Metal Forming Services is a dynamic and forward-thinking manufacturer that offers a comprehensive range of metal forming services. With their state-of-the-art facilities, skilled workforce, and commitment to quality, the company consistently delivers exceptional solutions to a diverse clientele. Through their ongoing investment in technology and environmentally friendly practices, Metal Forming Services sets itself apart as an industry leader that is capable of meeting the ever-changing demands of modern manufacturing.

New Standards for Advanced Cutting Machinery Released by Kunshan Manufacturer

Kunshan Qiankun Machinery Manufacturing Co., Ltd. has recently released their new line of CNC high-precision plasma cutting machines, slope CNC cutting machines, and Longmen laser cutting machines. These machines are designed to offer high precision laser cutting, making them a popular choice for industrial and commercial applications.Over the years, laser cutting machines have become a popular choice for cutting, engraving, and marking various materials like metal, wood, and plastic. As advancements continue to be made in laser cutting technology, the demand for high precision laser cutting machines has significantly increased.This is where Kunshan Qiankun Machinery Manufacturing Co., Ltd. comes in. They specialize in providing advanced CNC high-precision plasma cutting machines, slope CNC cutting machines, and Longmen laser cutting machines, which offer incredible accuracy and precision on a wide range of materials.Their CNC high-precision plasma cutting machine uses plasma to precisely cut through metal sheets, making it an excellent choice for manufacturers who need to cut thicker materials. It combines a precise cutting head with a powerful plasma generator, which can easily cut through thick sheets of metal quickly and precisely.The slope CNC cutting machine is another innovative solution that has been designed for accuracy and precision. This machine is suitable for cutting materials at different angles, making it a great choice for industries such as automotive, aerospace, and construction.And then there's the Longmen laser cutting machine, which is ideal for manufacturers that require high precision cutting on large materials. This machine has been designed to efficiently and precisely cut large material sheets with minimal errors, saving manufacturers time and money.These machines come with advanced features such as automatic edge detection, which ensures that the cut is made precisely, with no deviations. Additionally, these machines are built to withstand the rigors of industrial use, ensuring you can rely on them for long periods with minimal maintenance.In conclusion, the CNC high-precision plasma cutting machine, slope CNC cutting machine, and Longmen laser cutting machine from Kunshan Qiankun Machinery Manufacturing Co., Ltd. are excellent choices for manufacturers that demand precision and accuracy in their laser cutting operations.With advanced features, durable construction, and high cutting speeds, these machines are ideal for industries that require high precision laser cutting, including automotive, aerospace, construction, and manufacturing, among others. So if you're looking for an innovative solution for your laser cutting needs, Kunshan Qiankun Machinery Manufacturing Co., Ltd. has got you covered!

Top Fabrication Welding Techniques Unveiled: A Comprehensive Guide for Welding Enthusiasts

Title: Boosting the Future of Fabrication Welding: Revolutionizing Industries with Cutting-edge TechnologyIntroduction:Fabrication welding has been a critical component in various industries, ranging from construction and automotive to aerospace and manufacturing. However, with the ever-advancing technological landscape, it is crucial for businesses to embrace innovation to remain competitive in the market. Recognizing this need, a pioneering fabrication welding company has emerged, aiming to reshape the industry with its groundbreaking solutions.Company Overview:{Remove brand name}, a leading fabrication welding company, has positioned itself as a game-changer in the field. With an unwavering commitment to excellence, the company has been at the forefront of delivering top-notch welding services and innovative solutions to clients worldwide. {Replace with actual information about the company's history, achievements, and notable projects.}Cutting-Edge Technology:In an era driven by technological advancements, {Remove brand name} has embraced cutting-edge technologies, revolutionizing the fabrication welding industry. Through constant research and development, the company has introduced pioneering techniques that enhance efficiency, precision, and overall productivity for various welding applications.1. Robotics and Automation:{Remove brand name} leverages robotics and automation to streamline fabrication welding processes. By employing state-of-the-art robotic systems, repetitive and labor-intensive tasks can be completed with unparalleled accuracy, reducing the risk of errors and enhancing productivity. This not only saves time but also ensures consistent output, ensuring high standards of quality.Incorporating automated welding systems eliminates human error, enhances safety, and allows for precise control over welding parameters, resulting in flawless welds every time. A collaborative effort, combining the expertise of skilled technicians with robotic systems, allows businesses to obtain superior weld quality while increasing production capacity.2. Augmented Reality in Fabrication Welding:{Remove brand name} has also integrated augmented reality (AR) technology into fabrication welding processes. AR systems provide real-time visualization, overlaying digital design models onto the physical components, and guiding welders precisely for accurate positioning and alignment.AR technology offers comprehensive instructions, highlighting critical welding areas and providing valuable insights into the welding process. This not only improves overall precision but also reduces training time for new welders, empowering them to deliver exceptional results even with limited experience.3. Laser Welding:{Remove brand name} has recognized the potential of laser welding, a technique that utilizes high-intensity lasers to generate focused heat and join metals with minimal distortion. Laser welding is becoming increasingly popular due to its superior precision and the ability to weld even the most complex configurations with ease.With laser welding, {Remove brand name} enhances productivity, enabling faster production cycles while maintaining excellent weld quality. This advanced technique also minimizes post-welding processes such as polishing, reducing overall production costs and increasing customer satisfaction.Impact on Industries:The integration of these cutting-edge technologies has had a profound impact on numerous industries. From manufacturing to automotive and aerospace, {Remove brand name}'s revolutionary approach has resulted in enhanced productivity, improved quality control, cost reductions, and increased competitiveness for businesses operating in these sectors.The construction industry, for instance, benefits from the increased accuracy and efficiency of fabrication welding. Precise welding ensures structural integrity, minimizing safety hazards and ensuring compliance with stringent industry standards.The automotive sector, on the other hand, relies on the precise welding of intricate components, ensuring reliability and durability in vehicle manufacturing. Utilizing advanced fabrication welding techniques allows automotive manufacturers to produce safer and more efficient vehicles at a faster pace.Conclusion:{Remove brand name} has redefined the possibilities in the fabrication welding industry by embracing cutting-edge technologies. Through robotic automation, augmented reality, and laser welding techniques, the company has transformed fabrication welding, resulting in heightened precision, increased productivity, and cost-effectiveness across various industries.As technology continues to evolve, {Remove brand name} remains dedicated to pushing the boundaries of fabrication welding, driving innovations that will shape the future of the industry. By embracing these advancements, businesses can galvanize their operations, making significant strides towards success in an increasingly competitive global market.

How to Spot Weld Galvanized Steel: A Comprehensive Guide

Spot Weld Galvanized Steel: A Breakthrough in Welding TechnologyIn recent years, advancements in manufacturing technology have brought about significant improvements in various industrial sectors. These improvements aim to enhance both the quality and efficiency of production processes. One such breakthrough has been achieved by a leading company in the industry, yet for confidentiality reasons, we will refer to it as Company X.Company X, a renowned player in the fabrication industry, has come up with an innovative solution to spot weld galvanized steel. This groundbreaking technology has the potential to revolutionize the welding industry and provide numerous benefits to businesses across various sectors.Spot welding, a widely used technique in the manufacturing sector, involves joining two metal surfaces together using heat and pressure. Galvanized steel, a material commonly used in the automotive and construction industries, poses unique challenges during spot welding due to its zinc coating. Traditionally, the zinc coating caused electrode degradation and created an inferior weld, resulting in compromised structural integrity.Recognizing the limitations of traditional spot welding techniques, Company X has developed an advanced method that overcomes these challenges. By leveraging their expertise in materials science and cutting-edge research, Company X has successfully engineered a solution to spot weld galvanized steel with exceptional precision and durability.The key behind this breakthrough lies in the development of a specialized welding electrode. This electrode is designed to withstand the adverse effects of the zinc coating, ensuring a reliable and robust weld every time. Additionally, Company X's innovative electrode design optimizes the distribution of heat and pressure, resulting in a stronger bond between the metal surfaces.This groundbreaking technology not only guarantees high-quality welds but also offers several other advantages. Firstly, it significantly reduces production costs by eliminating the need for extra surface preparation steps such as zinc coating removal. The new method also streamlines the manufacturing process by simplifying the spot welding operation, thereby increasing productivity.Moreover, the improved structural integrity achieved through this breakthrough welding technology ensures enhanced safety and durability in the finished products. Applications in the automotive and construction sectors are particularly promising, as the spot welding of galvanized steel is a common requirement in these industries.Company X's commitment to innovation and continuous improvement has been instrumental in their success. Their state-of-the-art research and development facilities enable them to stay at the forefront of technological advancements in the welding industry. By investing in cutting-edge equipment and collaborating with industry experts, Company X has solidified its position as a leading provider of spot welding solutions worldwide.With the introduction of this breakthrough technology, Company X intends to expand its market share and further strengthen its reputation as an industry frontrunner. By offering a superior alternative to traditional spot welding methods, Company X is poised to capture the attention of manufacturers seeking higher-quality and cost-effective welding solutions.Furthermore, the rapid adoption of this innovative welding technique has the potential to revolutionize the industry as a whole. Other manufacturers are likely to follow suit, enhancing the overall quality and efficiency of spot welding galvanized steel products globally.In conclusion, Company X's groundbreaking breakthrough in spot welding galvanized steel has paved the way for a new era in manufacturing. With their innovative electrode design and unparalleled expertise, they have successfully overcome the challenges posed by the zinc coating, revolutionizing the welding industry. The introduction of this technology promises increased productivity, reduced production costs, and enhanced product quality. As other manufacturers catch on to the advancements made by Company X, we can expect significant transformations in the way galvanized steel is spot welded, opening doors to a more reliable and efficient future.

Plasma Cutting Machines Manufactured in China by Langzhi Factory for Sale: A Comprehensive Guide to Choosing Material and Application Techniques

CNC Plasma Cutting Service: Improving Precision and Efficiency of Industrial CuttingIn the industrial world, precision cutting is a necessity for achieving optimal efficiency and productivity. Technology has greatly advanced this sector with the advent of CNC plasma cutting machines.Plasma cutting is the process of cutting metals and other conductive materials by using a plasma torch powered by compressed gas and an electrical arc. CNC plasma cutting machines operate under computer numerical control (CNC) which allows for precise cutting according to programmed designs. These machines are widely used in industries such as automotive, construction, metal fabrication, and aerospace.China is one of the leading manufacturers of CNC plasma cutting machines, with Langzhi Plasma Cutting Machine among the top producers in the country. Their machines come in a wide range of sizes and configurations, suitable for various cutting needs.With CNC plasma cutting technology, businesses can achieve utmost precision with fast and smooth cutting. The accuracy of the cuts is not limited by human error, ensuring that the final product matches the design.Furthermore, the automation of the cutting process means that CNC plasma cutting is much faster than manual cutting methods. This leads to reduced lead times and faster turnaround for clients.CNC plasma cutting technology can also handle a wide variety of metals and alloys such as steel, aluminum, copper, and brass, making it versatile for different applications.Moreover, CNC plasma cutting can be utilized for both small and large-scale projects. From a simple design to a complex one, CNC plasma cutting delivers high-quality results consistently. It can handle thick and thin metal sheets with ease and precision.In addition, CNC plasma cutting is also a cost-effective solution. The investment in the technology pays off in the long-term by increasing efficiency and productivity, and reducing material waste through precise cutting.In conclusion, CNC plasma cutting is a valuable technology in the industrial sector. The benefits of CNC plasma cutting go beyond precision and speed, as it also offers versatility, cost-effectiveness, and consistency in quality of output.If you're looking to invest in CNC plasma cutting services, reach out to reputable manufacturers and suppliers in the industry. They can provide guidance and support in selecting the appropriate machine and materials to match your specific cutting needs.Overall, CNC plasma cutting is a vital innovation that is shaping the future of industrial cutting.

Metal Fabrication: A Guide to Building Metal Structures through Cutting, Bending, and Assembly Processes

Metal Fabrication Company Revolutionizes the Industry with Innovative SolutionsMetal fabrication is the process of utilizing a range of techniques to build structures, products, and components from metal materials. The industry has come a long way since the early days of hammering metal sheets together. Today, metal fabrication is an incredibly sophisticated process that involves cutting, shaping, and assembling metal into a variety of different products.Leading the way in the metal fabrication industry is (Brand Name Removed), a company committed to providing innovative solutions to clients’ metal fabrication needs. With their state-of-the-art techniques and technology, they have revolutionized how metal is fabricated and produced across the industry.Their metal fabrication process begins with cutting - using tools such as plasma cutters and water jets to carefully and accurately cut the metal into the required shapes. From there, the metal is shaped through processes such as bending and rolling, to create the necessary structures and components. Welding is then utilized to assemble these structures, completing the fabrication process.What sets (Brand Name Removed) apart from other metal fabrication companies is their dedication to investing in the latest technology and innovations. They have the capabilities to fabricate a wide range of metals, including steel, aluminium, and titanium - each with its unique properties and challenges. Their advanced techniques and skilled workforce mean that they can create highly complex, custom-made components, all while maintaining the highest levels of precision and accuracy.One particular aspect that has enabled (Brand Name Removed) to make significant strides forward is their incorporation of computer-aided design and finite element analysis. They utilize CAD/CAM software to create virtual models of the metal components before fabrication begins, allowing for a quicker and more efficient process. This also ensures that the final product meets the client's expected specifications.Another area of innovation for (Brand Name Removed) is their approach to sustainability. They strive to use environmentally friendly materials and techniques whenever possible to reduce the impact on the environment. This includes utilizing recycled materials in their fabrication processes and improving their waste management procedures.With over [insert number of years] years of experience in the metal fabrication industry, (Brand Name Removed) has built a reputation for excellence and quality. They work closely with clients across a range of industries, including aerospace, automotive, and construction, to provide bespoke metal solutions for their specific needs.Furthermore, (Brand Name Removed) offers a wide range of services to complement their metal fabrication capabilities. They offer CAD design, prototyping, repair, and maintenance services, ensuring clients have everything they need under one roof.Moreover, they have an exceptional quality control program, ensuring the compliance of the fabrication process with the highest industry standards. This is achieved through detailed process mapping, checks, and cross-checks at each step of the process.The metal fabrication industry is constantly evolving, and (Brand Name Removed) is taking the lead. Their pioneering approach, investment in the latest technology, and commitment to quality and sustainability mean that they are well-positioned to continue driving the industry forward.With an unwavering focus on innovation, quality, and sustainability, (Brand Name Removed) is set to remain at the forefront of the metal fabrication industry - delivering exceptional results for clients across the world.

Laser Cutting and Fabrication: A Comprehensive Guide for Precision Metal Work

Laser Cutting And Fabrication - Delivering Top Quality Products to CustomersFor all your metal fabrication needs, Laser Cutting And Fabrication is the solution you need! With extensive experience in the industry, we offer custom laser cutting and fabrication services for a wide range of materials, including stainless steel, aluminum, brass, and copper. Our team of certified professionals is committed to producing high-quality products that meet or exceed customer expectations.At Laser Cutting And Fabrication, we pride ourselves on being a highly reliable and trusted service provider. We stand by our commitment to quality and ensure that each job we undertake meets the highest industry standards. Our equipment uses the latest technology available to produce superior results, ensuring that even the most complex designs are finished with precision and accuracy.Our team of experts has years of experience in laser cutting and fabrication, enabling us to accurately assess your needs, requirements, and design ideas. We can design and create a wide variety of products such as metal signs, brackets, and enclosures. We can also create custom-made prototype parts for your business. Our laser cutting services are catered to the unique needs of our customers, so you can be assured that every product we create is tailored to your specific requirements.Our state-of-the-art equipment helps us to remain at the top of our game. We use the best tools to make our services stand out. Laser Cutting And Fabrication has the latest, up-to-date technology, allowing us to be highly adaptable and flexible when it comes to fulfilling customers' needs. Our computer software allows for seamless integration between 3D designs and production, reducing production time while also increasing precision.Our laser cutting and fabrication techniques use a non-contact cutting method, which ensures that each product is free from deformation and does not require extra processing. With the use of laser, we are able to accommodate the production of even the thinnest of metals, with a very precise cut. Our CNC machining center also provides us with high-quality milling and turning processes, allowing for streamlining of all production phases.At Laser Cutting And Fabrication, we understand the importance of delivering products that meet or even exceed our customer's expectations. Our team is committed to ensuring that the end result is of top quality and that each project is delivered on time. We maintain open communication throughout the production process, to ensure that the product we deliver meets the customer's expectations, even when changes are made to the design.Our aim is to create long-term partnerships with our clients, providing them with reliable and trustworthy laser cutting and fabrication services. We pride ourselves on being a one-stop-shop for all your needs, delivering comprehensive services from start to finish. We value our customers, and in turn, are dedicated to providing them with the highest quality of service.Laser Cutting And Fabrication is a company that believes in adding value at all times through continuous improvement, leading to simplified and affordable prices for customers. We understand that each customer has unique needs and requirements, which is why we offer a completely customized solution. From the moment we receive your inquiry, our team of professionals ensures that we create an exceptional experience for our customers.Our commitment to quality and excellence is what sets us apart. We understand that a company's reputation is dependent on the products it produces. As such, we aim to exceed customer expectations by providing them with exceptional service at every stage of the process. We maintain our relationship with our customers by providing a trusted source for laser cutting and fabrication services.In conclusion, Laser Cutting And Fabrication is more than a business; it is a partner in production. Our team is dedicated to quality, reliability, and customer satisfaction. We are more than willing to work with you to achieve the desired outcome, whether it be custom parts for your small business or large-scale fabrication. Choose us for all your laser cutting and fabrication needs, and experience the best of what this industry has to offer!