Professional Sheet Metal Prototype Fabrication Services for Your Business

By:Admin

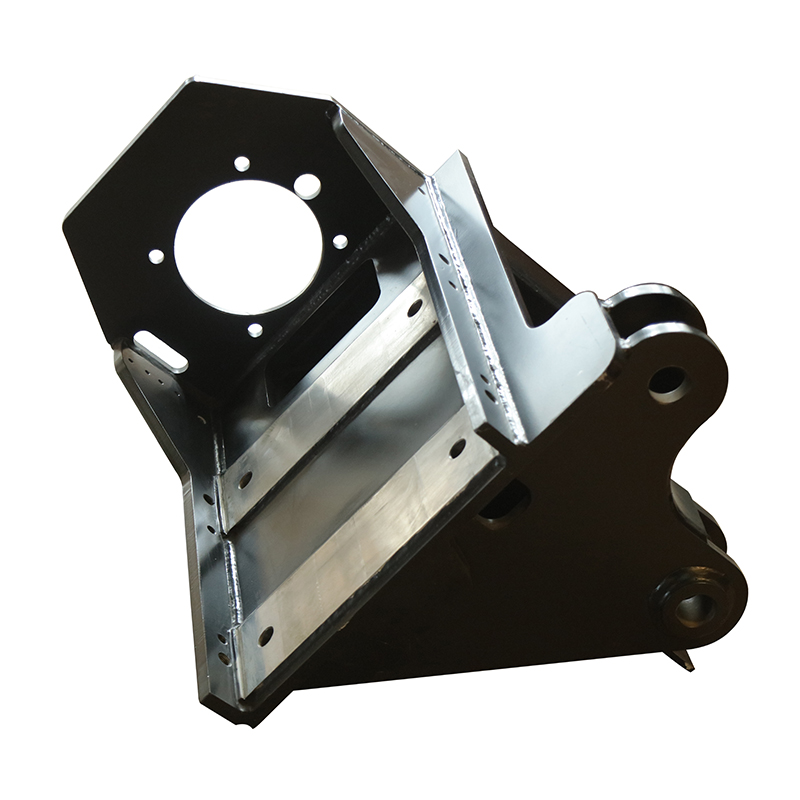

The new sheet metal prototype fabrication service is designed to cater to the growing demand for rapid prototyping and small-scale production in industries such as aerospace, automotive, electronics, and medical devices. With the ability to produce complex, high-precision sheet metal components, [Company Name] is well-positioned to meet the needs of customers looking to bring their designs to life quickly and efficiently.

"Our sheet metal prototype fabrication service is a natural extension of our capabilities as a precision engineering company," said [Spokesperson Name], CEO of [Company Name]. "We understand the importance of fast turnaround times and the need for high-quality prototypes in the product development process. Our new service will enable our customers to quickly test and iterate their designs before moving to full-scale production."

The sheet metal prototype fabrication process at [Company Name] begins with a thorough review of the customer's design requirements. The company's team of experienced engineers works closely with the customer to understand their specific needs and to ensure that the end product meets their exact specifications. Using state-of-the-art CAD/CAM software and CNC machining equipment, [Company Name] is able to produce highly accurate and repeatable sheet metal components.

With a wide range of materials available, including stainless steel, aluminum, and titanium, [Company Name] can accommodate a variety of design requirements and production needs. Whether customers require simple flat patterns or complex, multi-faceted components, the company's team of skilled technicians is capable of delivering on even the most challenging projects.

In addition to its cutting-edge fabrication capabilities, [Company Name] also offers a range of finishing services to ensure that the end product meets the highest standards of quality and aesthetic appeal. From deburring and grinding to powder coating and plating, the company has the expertise to add the finishing touches that will make each component stand out.

The launch of the sheet metal prototype fabrication service is a testament to [Company Name]'s commitment to staying at the forefront of the industry. By investing in the latest technology and continually expanding its capabilities, the company is well-positioned to meet the evolving needs of its customers and to maintain its reputation as a trusted partner for precision engineering solutions.

"We are proud to introduce our new sheet metal prototype fabrication service, which we believe will be a game-changer for our customers," said [Spokesperson Name]. "With this new offering, we are further solidifying our position as a one-stop shop for all precision engineering needs. We are excited to see the impact that this new service will have on our customers' product development efforts."

As [Company Name] continues to grow and expand its capabilities, the launch of the sheet metal prototype fabrication service is a clear indication of the company's commitment to innovation and customer satisfaction. With its unparalleled expertise, state-of-the-art equipment, and dedication to quality, [Company Name] is well-positioned to continue delivering exceptional results for its customers across a wide range of industries.

Company News & Blog

High-Quality Metal Cutting Services: A Comprehensive Guide

Metal Cutting Service Expands Production Capacity to Meet Growing DemandMetal Cutting Service, a leading provider of metal cutting solutions, has recently expanded its production capacity to meet the growing demand for its services.With over a decade of experience in the industry, Metal Cutting Service has earned a reputation for delivering high-quality precision cutting services to a wide range of industries, including automotive, aerospace, and manufacturing. The company is known for its state-of-the-art equipment and highly skilled team of technicians, who are able to handle a variety of metal cutting tasks with precision and efficiency.The recent expansion of production capacity comes in response to an increase in demand for Metal Cutting Service's services. As the manufacturing sector continues to grow, the need for high-quality metal cutting services has become more pronounced. Metal Cutting Service has positioned itself as a go-to provider for companies in need of precision metal cutting solutions, and the expansion of its production capacity will allow the company to better serve its clients and take on larger projects."We are pleased to announce the expansion of our production capacity," said the CEO of Metal Cutting Service. "This expansion will allow us to keep up with the increasing demand for our services and continue to provide the high-quality metal cutting solutions that our clients have come to expect from us. We are committed to investing in our capabilities and infrastructure to ensure that we can meet the evolving needs of our clients in today's fast-paced manufacturing environment."The expansion of production capacity at Metal Cutting Service includes the addition of new cutting machines, as well as the hiring of additional skilled technicians to operate the equipment. The company has also invested in advanced training programs to ensure that its team is equipped with the latest techniques and best practices in the industry.In addition to the expansion of production capacity, Metal Cutting Service has also focused on improving its efficiency and turnaround times. The company has implemented streamlined processes and advanced scheduling systems to ensure that it can deliver its services in a timely manner, even for large-scale projects."We understand the importance of efficiency and reliability in the metal cutting industry," said the CEO. "That's why we have made significant investments in our infrastructure and processes to ensure that we can meet our clients' deadlines and deliver high-quality results on every project."Metal Cutting Service's commitment to quality and customer satisfaction has earned it a loyal customer base and a strong reputation in the industry. The company's expansion of production capacity reflects its dedication to meeting the evolving needs of its clients and maintaining its position as a leader in the metal cutting sector."We are grateful for the support of our clients and the trust they have placed in us," said the CEO. "We are excited to be able to offer even more capabilities and capacity to serve them better and continue to help them succeed in their own businesses."As Metal Cutting Service expands its production capacity and continues to invest in its capabilities, the company is well-positioned to meet the growing demand for its services and remain a top choice for precision metal cutting solutions in the industry. With its state-of-the-art equipment, skilled team, and commitment to excellence, Metal Cutting Service is poised for continued success and growth in the years to come.

Essential Techniques for Welding Stainless Steel Pipes: A Comprehensive Guide

Stainless Steel Pipe Welding: Delivering Quality and Precision(Company Introduction)In a rapidly evolving industrial landscape, companies must constantly innovate to stay ahead of the competition. One such enterprise leading the charge is {{Company Name}}, a market leader in the stainless steel industry. With years of experience and a dedication to quality, they have revolutionized the world of stainless steel pipe welding.(Opening Paragraph)Stainless steel pipes play a crucial role in various industries, including oil and gas, construction, and manufacturing. Their ability to withstand extreme temperatures, pressure, and corrosion makes them an essential component in many applications. However, it is the welding process that truly determines the integrity and durability of these pipes.(Main Body - Paragraph 1)Recognizing the critical importance of stainless steel pipe welding, {{Company Name}} has invested heavily in state-of-the-art technology and equipment. Equipped with cutting-edge welding machines, they ensure the highest standards of quality and precision in every welded joint. The company also places significant emphasis on continuous training and development of its welding technicians, allowing them to maintain the highest level of expertise in the industry.(Main Body - Paragraph 2)Precision is a key factor in stainless steel pipe welding, as even the tiniest of flaws can compromise the integrity of the final product. {{Company Name}} utilizes advanced welding techniques, such as Tungsten Inert Gas (TIG) and Metal Inert Gas (MIG), to achieve flawless welds. Through meticulous control of the welding parameters, including voltage, current, and speed, they guarantee consistent and reliable welds, meeting the stringent requirements of various industries.(Main Body - Paragraph 3)Quality assurance is at the core of {{Company Name}}'s operations. Every welded joint undergoes rigorous testing and inspection to ensure conformity to international standards. Non-destructive testing techniques, such as ultrasonic testing and radiographic examination, are employed to detect any hidden flaws or defects. By adhering to these strict quality control measures, {{Company Name}} has earned an impeccable reputation for supplying stainless steel pipes of superior quality.(Main Body - Paragraph 4){{Company Name}} takes environmental responsibility seriously. Through the implementation of environmentally friendly welding processes, such as low-emission welding techniques, they reduce the carbon footprint associated with stainless steel pipe manufacturing. This commitment to sustainability not only benefits the environment but also demonstrates {{Company Name}}'s dedication to meeting the evolving needs of socially conscious industries.(Main Body - Paragraph 5)As the demand for stainless steel pipes continues to grow, {{Company Name}} remains at the forefront of innovation. Their research and development department is constantly exploring new materials, welding techniques, and technologies to further enhance the performance and longevity of their products. By staying ahead of the curve, they ensure that their customers always receive the most cutting-edge solutions for their specific applications.(Closing Paragraph)With a steadfast commitment to quality, precision, and innovation, {{Company Name}} has become a trusted partner for businesses worldwide, seeking exceptional stainless steel pipe welding solutions. Their unwavering dedication to customer satisfaction, coupled with their continuous drive for excellence, positions them as an industry leader in the competitive stainless steel market.

Leveraging the Power of CNC Laser Services for Your Business's Needs

CNC Laser Service Launches Cutting-Edge Laser Technology to Meet the Needs of Modern BusinessesThe world of manufacturing and industrial production is constantly evolving, and businesses that want to stay ahead of the curve need to stay up to date with the latest technology. That's why CNC Laser Service (name removed) has recently launched their latest laser cutting system, designed to meet the needs of today's businesses.At CNC Laser Service, we have been providing high-quality laser cutting solutions to our customers for over twenty years. During that time, we have built a reputation for excellence, innovation, and customer service, and we are committed to continuing to meet the evolving needs of our clients.Our latest laser cutting system is a testament to that commitment, incorporating the latest technology and design features to deliver precision cutting solutions that are unmatched in the industry. With CNC Laser Service's state-of-the-art system, businesses can quickly and easily create custom parts, prototypes, and products with the highest level of accuracy and efficiency.One of the key benefits of CNC Laser Service's new laser cutting system is its speed. The system can produce parts and products at a significantly faster pace than traditional cutting methods, which means businesses can bring their products to market much more quickly. This speed also allows for faster changes and modifications to products, which is essential in today's fast-paced business environment.The precision of our system is another crucial attribute. Our laser cutting technology allows us to make cuts with an accuracy of 0.001 of an inch, which means we can create parts and products that are incredibly precise, with no room for error. This level of precision not only ensures the final product is of the highest quality, but it also minimizes waste and reduces costs associated with errors or rework.Another feature that sets CNC Laser Service's cutting-edge laser technology apart from traditional manufacturing solutions is its flexibility. Our system can work with a wide range of materials, including metals, plastics, and even delicate materials such as fabrics and ceramics. This versatility means we can tailor our processes to meet the unique needs of each of our clients, covering a wide range of industries.CNC Laser Service's laser machine also offers a high level of customization, allowing us to create parts and products with unique shapes, sizes, and textures. This customization is a vital feature for businesses that need to create parts that are tailored to specific needs, such as the medical or aerospace industries.Finally, our system's automation capabilities allow us to streamline our processes and reduce the need for manual labor, which translates to lower costs and faster turnaround times for our clients. Our laser cutting system allows us to quickly and easily produce large quantities of parts, making it an ideal solution for businesses with high-volume manufacturing needs.At CNC Laser Service, we are incredibly proud of our latest laser cutting system and the benefits it offers our clients. With its speed, precision, flexibility, customization, and automation capabilities, our technology is poised to take businesses to the next level of manufacturing excellence.Whether you're in the automotive, medical, aerospace, defense, or any other industry, CNC Laser Service's laser cutting system has the capability to meet your unique needs. We invite you to contact us today to learn more about our cutting-edge technology and discover how we can help you take your business to the next level of success.

Welding Zinc Coated Steel: Tips and Techniques for Mig Welders

Mig Welding Zinc Coated Steel for Stronger and More Durable Products{Company Name}, a leading manufacturer in the steel industry, is proud to announce the implementation of Mig welding technology for zinc coated steel products. This innovative welding process will result in stronger and more durable steel products, further solidifying {Company Name}’s reputation for high-quality materials and advanced manufacturing techniques.As a company dedicated to providing the best products to our customers, we are constantly looking for ways to improve the quality and durability of our steel. Mig welding technology offers significant advantages in terms of strength and consistency, making it the ideal choice for welding zinc coated steel.Zinc coated steel is widely used in various industries due to its excellent corrosion resistance and long-lasting performance. By incorporating Mig welding technology, {Company Name} aims to enhance these already impressive qualities, ensuring that our customers receive the most reliable and durable steel products on the market.Mig welding, also known as Gas Metal Arc Welding (GMAW), is a process that uses a continuous solid wire electrode and shielding gas to create strong, high-quality welds. This technique is known for its versatility and ability to produce precise and uniform welds, making it the perfect choice for welding zinc coated steel.The implementation of Mig welding technology is a testament to {Company Name}’s commitment to staying at the forefront of innovation in the steel industry. By investing in the latest welding techniques, we are able to offer our customers superior steel products that meet the highest standards of quality and performance.In addition to Mig welding technology, {Company Name} also prides itself on utilizing state-of-the-art manufacturing processes and cutting-edge equipment. Our facilities are equipped with the latest technology to ensure the highest level of precision and efficiency in every step of the production process.With a team of highly skilled and experienced professionals, {Company Name} has built a reputation for delivering top-quality steel products that exceed our customers’ expectations. Our dedication to excellence and continuous improvement has allowed us to become a trusted partner for companies in a wide range of industries, from construction and infrastructure to automotive and manufacturing.Incorporating Mig welding technology for zinc coated steel is just one example of {Company Name}’s ongoing efforts to enhance our product offerings and provide our customers with the best steel solutions available. We take pride in our ability to adapt to the latest advancements in the industry and consistently raise the bar for quality and performance.As we move forward with the implementation of Mig welding technology, we are excited about the possibilities it presents for the future of our steel products. By leveraging this innovative welding process, we aim to set new standards for strength, durability, and overall product excellence in the steel industry.{Company Name} is committed to maintaining our position as a leader in the steel manufacturing sector, and we will continue to explore new technologies and approaches to ensure that our customers receive the finest steel products on the market. We are confident that the implementation of Mig welding technology for zinc coated steel will further solidify our reputation for excellence and quality in the industry.In conclusion, {Company Name}’s adoption of Mig welding technology for zinc coated steel represents a significant advancement in our ongoing commitment to delivering the best steel products to our customers. This innovative welding process will result in stronger, more durable steel products, further establishing {Company Name} as a reliable source for high-quality materials and advanced manufacturing techniques. With our dedication to excellence and continuous improvement, {Company Name} is proud to be at the forefront of innovation in the steel industry and looks forward to setting new standards for product quality and performance.

Fiber Laser Engraving Service: Enhancing Precision and Efficiency for Your Engraving Needs

Efficient and Precise Steel Flame Cutting Services

Flame cutting steel is a method used in the manufacturing industry to shape and manipulate steel into various forms. This process involves using a high-temperature flame to cut through steel, resulting in precise and clean cuts. It is a widely used technique in many industries, including construction, automotive, and machinery manufacturing.One company that specializes in flame cutting steel is {}. With over 20 years of experience in the steel fabrication industry, {} has established itself as a leading provider of high-quality flame-cut steel products. The company prides itself on its advanced technology, skilled workforce, and commitment to delivering top-notch products to its customers.{} offers a wide range of flame-cut steel products, including steel plates, sheets, and custom-cut shapes. Their state-of-the-art facility is equipped with the latest flame cutting machinery, allowing them to handle large-scale production while maintaining high precision and quality. In addition to their cutting-edge technology, {} also places a strong emphasis on safety and environmental sustainability in their manufacturing processes.One of the key advantages of flame cutting steel is its ability to cut through thick steel materials with ease. This makes it an ideal method for producing heavy-duty components such as structural beams, machinery parts, and high-strength steel plates. Furthermore, flame cutting allows for a high degree of customization, making it possible to create complex shapes and designs according to specific customer requirements.The use of flame cutting steel has become increasingly popular in the manufacturing industry due to its cost-effectiveness and efficiency. With the ability to produce large quantities of accurately cut steel components in a relatively short amount of time, companies like {} are able to meet the demands of their customers while maintaining competitive pricing.Furthermore, the versatility of flame cutting steel makes it suitable for a wide range of applications. From building construction to industrial machinery, flame-cut steel products play a vital role in numerous sectors of the economy. As such, {} has positioned itself as a reliable and trusted supplier of flame-cut steel products to various industries.In addition to its commitment to quality and efficiency, {} also places a strong emphasis on customer satisfaction. The company works closely with its clients to understand their specific needs and provides tailored solutions to meet their requirements. With a dedicated team of experts and engineers, {} is able to offer technical support and consultation throughout the production process, ensuring that their customers receive the best possible outcome.As the demand for flame-cut steel products continues to grow, {} remains at the forefront of the industry, continuously investing in technologies and processes to meet the evolving needs of its customers. The company's dedication to excellence and innovation has solidified its reputation as a premier provider of flame-cut steel products in the market.In conclusion, flame cutting steel is a crucial process in the manufacturing industry, with {} standing out as a leading expert in this field. With its cutting-edge technology, skilled workforce, and commitment to customer satisfaction, {} continues to set the standard for excellence in the production of flame-cut steel products. As the industry evolves, {} remains dedicated to providing high-quality, customized solutions to its customers, ensuring their continued success in the market.

Benefits of Using Laser Technology for Stainless Steel Applications

Laser Stainless Steel, a leading manufacturer of stainless steel products, has been making waves in the industry with its innovative and high-quality offerings. Founded in 2005, Laser Stainless Steel has quickly become a trusted name in the stainless steel manufacturing sector, producing a wide range of products for various industries.The company's state-of-the-art manufacturing facilities and cutting-edge technology have set it apart from its competitors. Laser Stainless Steel's dedication to quality and precision has made it a preferred supplier for many businesses around the world.One of the key factors contributing to Laser Stainless Steel's success is its commitment to innovation. The company is constantly investing in research and development to improve its products and processes. This dedication to innovation has allowed Laser Stainless Steel to stay ahead of the curve and adapt to the ever-changing needs of the industry.Laser Stainless Steel offers a comprehensive range of stainless steel products, including sheets, coils, plates, pipes, tubes, and fittings. The company's products are known for their durability, corrosion resistance, and aesthetic appeal, making them ideal for a wide range of applications.In addition to its standard product offerings, Laser Stainless Steel also provides custom solutions for clients with specific requirements. The company's team of experienced engineers and designers work closely with clients to develop tailor-made products that meet their exact specifications. This personalized approach has earned Laser Stainless Steel a reputation for delivering bespoke solutions that exceed customer expectations.Laser Stainless Steel's dedication to quality is reflected in its adherence to international standards and certifications. The company holds ISO 9001 certification, ensuring that its products meet the highest quality standards. This commitment to quality assurance has earned Laser Stainless Steel the trust and confidence of its customers, who rely on the company's products for their critical applications.In addition to its focus on quality and innovation, Laser Stainless Steel prioritizes sustainability in its operations. The company is committed to environmentally friendly manufacturing practices, minimizing its impact on the planet. Laser Stainless Steel's sustainable approach has resonated with environmentally conscious clients who seek eco-friendly solutions for their projects.Laser Stainless Steel's strong commitment to customer satisfaction sets it apart from its competitors. The company places a high priority on building long-term relationships with its clients, working closely with them to understand their needs and deliver solutions that add value to their businesses. This customer-centric approach has resulted in a loyal customer base that continues to rely on Laser Stainless Steel for their stainless steel requirements.As a global leader in stainless steel manufacturing, Laser Stainless Steel serves a diverse range of industries, including construction, automotive, aerospace, healthcare, and more. The company's products are trusted by clients around the world for their quality, reliability, and performance.Looking ahead, Laser Stainless Steel is focused on expanding its product portfolio and strengthening its position as a market leader in stainless steel manufacturing. The company continues to invest in research and development, exploring new technologies and materials to develop innovative solutions for its clients.In conclusion, Laser Stainless Steel's dedication to quality, innovation, sustainability, and customer satisfaction has solidified its position as a leading manufacturer of stainless steel products. With a strong track record of delivering high-quality solutions for diverse industries, Laser Stainless Steel is poised for continued success and growth in the global market.

Discover Top-quality Bending Products and Services on Ferret.com.au

Are you searching for efficient and reliable CNC bending services for your business needs? Look no further than www.ferret.com.au to cater to all your bending requirements.At www.ferret.com.au, we offer a wide range of bending products and services from leading suppliers in the industry. Our suppliers are reputable and well-established, ensuring that you get the best quality products and services at an affordable price.CNC bending services are a vital component in the manufacturing industry. CNC (Computer Numerical Control) bending service is a highly automated process that reduces human error and increases efficiency. This advanced technology makes it possible to achieve high accuracy and precision in bending metal sheets.Our suppliers use modern CNC bending machines that are versatile and capable of bending different types of metal sheets in a range of sizes and thicknesses. These machines can also bend metal pipes and tubes, making them ideal for different manufacturing applications.CNC bending services offered at www.ferret.com.au include press brake bending, tube bending, and roll bending. Press brake bending is suitable for producing parts in large quantities and is used for both simple and complex bending operations. Tube bending is ideal for creating complex shapes and designs, while roll bending is ideal for producing curved and circular metal parts.We understand the importance of delivering high-quality products and services to our customers. Therefore, our suppliers use only the best materials and processes to ensure that the end product meets or exceeds your expectations.Our suppliers also offer customized CNC bending services to cater to specific needs and requirements. They work closely with customers to ensure that the end product meets their precise specifications. This personalized approach ensures that every customer gets the best possible bending solution for their business.In conclusion, if you require CNC bending services for your manufacturing needs, look no further than www.ferret.com.au. We offer a wide range of bending products and services from reputable and reliable suppliers in the industry. Our suppliers use modern CNC bending machines to provide high-quality products and services that meet or exceed your expectations. Contact us today to get started on your CNC bending project!

Custom Steel Plate Fabrication Services for Your Project Needs

[Company Name] Strengthens Steel Plate Fabrication Capabilities[City, State] – [Date] – [Company Name], a leading provider of fabrication and manufacturing services, has announced the expansion of its steel plate fabrication capabilities. With this investment, the company aims to meet the growing demand for high-quality steel plate products across various industries.Steel plate fabrication is a critical process in the manufacturing and construction sectors, as it involves shaping and forming steel plates to create structural components for buildings, machinery, and equipment. With the latest enhancement in [Company Name]’s fabrication division, the company can now offer a wider range of steel plate fabrication services to its clients.The expansion of [Company Name]’s steel plate fabrication capabilities includes the addition of advanced machinery and equipment, as well as the hiring of skilled fabricators and engineers. This investment allows the company to take on larger and more complex projects, while ensuring precision and efficiency in the fabrication process.“We are excited to announce the expansion of our steel plate fabrication capabilities,” said [Spokesperson’s Name], [Title] at [Company Name]. “With the increased demand for steel plate products in various industries, it was essential for us to bolster our capabilities in this area. This enhancement not only strengthens our position in the market but also enables us to better serve our clients with top-notch fabrication solutions.”[Company Name] has built a strong reputation for delivering high-quality fabrication and manufacturing services to a diverse clientele. The company’s commitment to excellence, combined with its state-of-the-art facilities and experienced team, positions it as a preferred partner for companies seeking reliable fabrication solutions.In addition to its expanded steel plate fabrication capabilities, [Company Name] offers a comprehensive range of services, including welding, machining, assembly, and finishing. The company caters to various industries, such as aerospace, automotive, construction, energy, and manufacturing, providing tailored solutions to meet each client’s specific needs.“We take pride in our ability to deliver customized fabrication services that address the unique requirements of our clients,” added [Spokesperson’s Name]. “Our team works closely with customers to understand their projects and provide cost-effective solutions that align with their goals. Whether it’s a small-scale prototype or a large-scale production run, [Company Name] has the expertise and resources to deliver exceptional results.”With its strengthened steel plate fabrication capabilities, [Company Name] is well-positioned to take on a wide range of projects, from small-scale components to large structural assemblies. The company’s commitment to quality, precision, and customer satisfaction sets it apart as a leader in the fabrication industry.As [Company Name] continues to expand its capabilities and enhance its service offerings, the company remains dedicated to driving innovation and exceeding client expectations. With a focus on continuous improvement and investment in cutting-edge technology, [Company Name] is poised for sustained growth and success in the fabrication and manufacturing sectors.For more information about [Company Name] and its fabrication services, visit [Company Website].About [Company Name]:[Company Name] is a leading provider of fabrication and manufacturing services, serving clients in various industries. With a focus on quality, innovation, and customer satisfaction, the company offers a comprehensive range of solutions, including steel plate fabrication, welding, machining, assembly, and finishing. [Company Name] is committed to delivering exceptional results and tailored services to meet the unique needs of its clients. For more information, visit [Company Website].