Professional Metal Fabrication Services for Quality Results

By:Admin

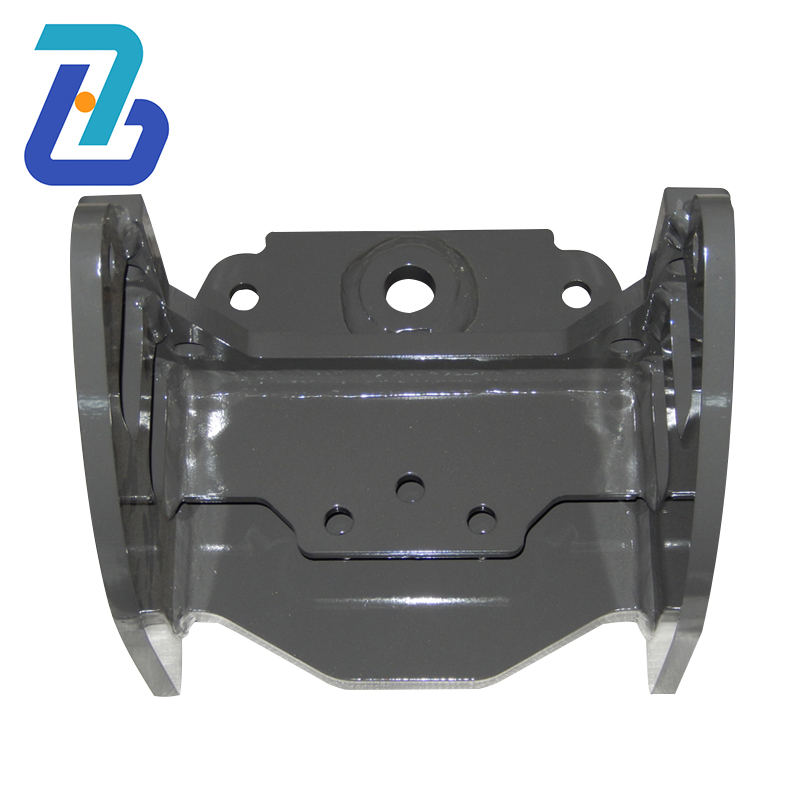

With over 20 years of experience in the industry, Metal Fabrication Works has established a solid reputation for delivering high-quality products and exceptional customer service. The company's state-of-the-art facilities and team of skilled professionals enable them to handle complex fabrication projects with precision and efficiency. From design and engineering to manufacturing and finishing, Metal Fabrication Works is committed to providing cost-effective and reliable solutions to their clients.

One of the key factors that sets Metal Fabrication Works apart from their competitors is their ability to offer customized solutions tailored to the specific needs of their clients. Whether it's a one-off prototype or a large-scale production run, the company has the capabilities to deliver products that meet the highest standards of quality and performance.

Metal Fabrication Works' commitment to excellence is evident in their dedication to continuous improvement and investment in the latest technologies. By staying ahead of industry trends and advancements, the company is able to offer cutting-edge fabrication solutions that are both innovative and efficient.

In addition to their technical expertise, Metal Fabrication Works places a strong emphasis on customer satisfaction. The company works closely with their clients to understand their needs and expectations, and strives to exceed them at every opportunity. Whether it's providing regular progress updates or offering post-production support, Metal Fabrication Works is dedicated to building long-lasting relationships with their clients based on trust and reliability.

Metal Fabrication Works' diverse portfolio of projects speaks to their versatility and adaptability. From small-scale custom fabrications to large-scale production runs, the company has the capacity to handle projects of all sizes and complexities. Their commitment to quality and customer satisfaction has earned them the trust of clients from various industries, making them a preferred partner for metal fabrication needs.

Metal Fabrication Works also takes pride in their commitment to environmental sustainability. The company adheres to strict environmental standards and practices responsible waste management to minimize their environmental impact. By incorporating sustainable practices into their operations, Metal Fabrication Works is able to contribute to a cleaner and greener future for the industry and the community.

The company's dedication to excellence, innovation, and sustainability has positioned Metal Fabrication Works as a leader in the metal fabrication industry. With a strong track record of delivering superior products and outstanding service, the company continues to set the standard for quality and reliability in the industry.

As Metal Fabrication Works looks to the future, they remain committed to upholding their values and exceeding the expectations of their clients. By staying at the forefront of technological advancements and industry best practices, the company is poised to continue providing cutting-edge metal fabrication solutions for years to come. With a steadfast commitment to excellence and customer satisfaction, Metal Fabrication Works is a trusted partner for all metal fabrication needs.

Company News & Blog

Top 5 Custom Metal Fabrication Services to Enhance Your Business

Custom Metal Fabrication Services has been providing top-quality metal fabrication services for over a decade. The company has carved a niche for itself in the industry thanks to its commitment to producing the highest-quality products for its clients, while staying up-to-date with the latest technologies and techniques.The company offers a wide range of custom metal fabrication services to businesses across various industries, including aerospace, automotive, food and beverage, and more. The team comprises highly-skilled and experienced fabricators that are passionate about delivering exceptional results."We are proud to offer our clients a wide range of custom metal fabrication services, each tailored to meet their specific needs," said a company representative. "We are committed to ensuring that our clients get the best possible results, and we are relentless in our pursuit of excellence."Custom Metal Fabrication Services utilizes the latest technologies and materials to produce products that meet the highest-quality standards. They specialize in working with a variety of materials, including carbon steel, aluminum, stainless steel, and more.The company offers a range of services that includes designing, prototyping, manufacturing, finishing, and installation. They work closely with their clients throughout the entire process, ensuring that their unique needs are met and that their expectations are exceeded.At Custom Metal Fabrication Services, quality is of utmost importance. The company has a comprehensive quality control process in place, which ensures that every product that leaves their facility meets the required quality standards. Every project is carefully monitored and tested to ensure that it meets the client's specific requirements.The company's commitment to quality has earned them a reputation as a trusted provider of custom metal fabrication services. Clients can always count on them to deliver exceptional results on time and within budget.In addition to providing high-quality metal fabrication services, Custom Metal Fabrication Services is also committed to providing exceptional customer service. Their team is always available to assist clients throughout the entire process, from the initial consultation to the final installation."We understand that our clients have unique needs, and we are always willing to go above and beyond to ensure that those needs are met," said the company representative. "Our team is passionate about what we do, and we are committed to delivering outstanding results and exceptional customer service, every time."Custom Metal Fabrication Services has invested heavily in the latest technologies and equipment to ensure that they stay ahead of the curve in the metal fabrication industry. They are constantly exploring new ways to improve their processes and techniques to deliver the best possible results for their clients.Whether it's a small or large project, Custom Metal Fabrication Services is equipped to handle it. They have the resources, skills, and experience necessary to take on any project, from simple designs to complex custom fabrications.In conclusion, Custom Metal Fabrication Services is a premier provider of custom metal fabrication services. Their commitment to quality, exceptional customer service, and staying up-to-date with the latest technologies and techniques has earned them a reputation as a trusted provider in the industry. Businesses looking for top-quality metal fabrication services can count on Custom Metal Fabrication Services to deliver the results they need.

High-Quality CNC Machining and Sand Blasting Services for Aluminum Materials

Axis CNC Machining Sand Blasting AluminumThe process of CNC machining and sand blasting aluminum is a crucial part of the manufacturing industry. It requires precision, skill, and expertise to produce high-quality aluminum parts that are used in various industries such as aerospace, automotive, and electronics. {Company Name} is a leading provider of axis CNC machining and sand blasting services for aluminum materials. With their state-of-the-art facilities and highly skilled team, they are able to deliver top-quality products to meet the needs of their customers.Axis CNC machining is a computer-controlled process that uses multi-axis machines to remove material from aluminum blocks and create precision parts. This process is highly efficient and accurate, ensuring that the final products meet the exact specifications required by the customers. With the advanced technology used by {Company Name}, they are able to produce complex and intricate aluminum parts with tight tolerances, making them a preferred choice for many businesses in need of high-precision components.In addition to CNC machining, {Company Name} also provides sand blasting services for aluminum materials. Sand blasting is a surface treatment process that uses abrasive materials to clean, smooth, or shape a hard surface. In the case of aluminum, sand blasting can be used to remove any surface impurities, create a matte finish, or prepare the material for further coating or painting. The skilled technicians at {Company Name} have the expertise to carry out sand blasting with precision and attention to detail, ensuring that the aluminum parts are of the highest quality and finish.One of the key advantages of axis CNC machining and sand blasting aluminum at {Company Name} is their commitment to quality and continuous improvement. They have implemented strict quality control measures at every stage of the manufacturing process to ensure that the final products meet the highest standards. This includes thorough inspections, rigorous testing, and adherence to industry regulations and guidelines. As a result, customers can have full confidence in the reliability and durability of the aluminum parts produced by {Company Name}.Furthermore, {Company Name} takes pride in their dedication to customer satisfaction. They work closely with their clients to understand their specific requirements and provide tailored solutions to meet their needs. Whether it's a one-off prototype or a large-scale production run, {Company Name} has the capacity and capability to deliver on time and within budget. Their customer-centric approach has earned them a solid reputation in the industry, making them a trusted partner for businesses looking for high-quality axis CNC machining and sand blasting services for aluminum materials.The team at {Company Name} is comprised of highly skilled and experienced professionals who are passionate about their craft. They are committed to staying ahead of the curve in terms of technology, techniques, and industry trends to ensure that they continue to deliver excellence in every project they undertake. Their expertise, dedication, and attention to detail are what set them apart from their competitors, making them a go-to source for axis CNC machining and sand blasting aluminum.In conclusion, axis CNC machining and sand blasting are essential processes in the manufacturing of aluminum parts, and {Company Name} is a trusted provider of these services. With their advanced technology, skilled team, and commitment to quality, they are able to produce high-precision aluminum components for various industries. Their customer-centric approach and dedication to excellence make them a valuable partner for businesses in need of top-quality axis CNC machining and sand blasting services.

Ultimate Guide to Steel Profile Cutting

Steel Profile Cutting, a subsidiary of (company name), is making waves in the steel cutting industry with its innovative technologies and commitment to delivering high-quality products to its customers. With a strong focus on precision and efficiency, Steel Profile Cutting has become a leader in the field, serving a wide range of industries including construction, automotive, and manufacturing.One of the keys to Steel Profile Cutting’s success is its state-of-the-art equipment, including the latest in CNC plasma and oxy-fuel cutting machines. These machines allow for highly accurate and clean cuts, ensuring that the finished products meet the highest standards of quality. In addition, the company’s team of skilled technicians is dedicated to providing personalized service to each customer, ensuring that their specific needs are met with precision and attention to detail.In addition to its cutting-edge technology, Steel Profile Cutting prides itself on its commitment to sustainability and environmental responsibility. The company utilizes advanced recycling processes to minimize waste and reduce its carbon footprint, making it a trusted partner for environmentally conscious businesses. By prioritizing sustainability, Steel Profile Cutting is not only meeting the demands of its customers, but also contributing to a more sustainable future for the steel industry as a whole.Despite its success and growth, Steel Profile Cutting remains dedicated to its core values of integrity, honesty, and customer satisfaction. The company’s team understands the importance of building strong relationships with its clients, and goes above and beyond to ensure that every project is completed to the highest standard. This commitment to excellence has earned Steel Profile Cutting a reputation as a trusted and reliable partner in the steel cutting industry.One recent project that showcases Steel Profile Cutting’s capabilities is the fabrication of custom steel profiles for a major construction project. The client, a leading construction company, required a high volume of precision-cut steel profiles to be used in the construction of a new commercial building. Steel Profile Cutting was able to meet the client’s specifications with accuracy and efficiency, delivering the finished products ahead of schedule and exceeding the client’s expectations.In addition to its commercial projects, Steel Profile Cutting also serves individual customers with custom cutting services for a wide range of applications. Whether it’s a small DIY project or a large-scale industrial application, the company is committed to providing the same level of quality and precision to every client, regardless of the size of the project. This dedication to customer satisfaction has earned Steel Profile Cutting a loyal and satisfied customer base, further solidifying its position as a leader in the industry.Looking ahead, Steel Profile Cutting is poised for continued growth and success, with plans to expand its capabilities and reach new markets. By staying at the forefront of technological advancements and continuously improving its processes, the company aims to remain a top choice for customers in need of high-quality steel cutting solutions. With its unwavering commitment to excellence and customer satisfaction, Steel Profile Cutting is set to continue making a significant impact in the steel cutting industry for years to come.

Top Trends in Industrial Metal Fabrication You Need to Know

Industrial Metal Fabrication Company Announces Expansion Plans{Company Name} is a leading industrial metal fabrication company known for its high-quality products and services. With over 20 years of experience in the industry, the company has built a strong reputation for delivering precision metal fabrication solutions to a wide range of industries including aerospace, automotive, construction, and more.In a recent announcement, {Company Name} revealed its plans for expansion to meet the growing demand for its products and services. The expansion will include the construction of a new state-of-the-art manufacturing facility and the addition of advanced machinery and equipment to increase production capacity.The decision to expand comes as a result of the company's continuous growth and success in serving its clients' needs for custom metal fabrication solutions. With an increasing number of orders and a growing customer base, {Company Name} is committed to investing in its infrastructure to ensure that it can continue to meet and exceed the expectations of its clients.The new manufacturing facility will be equipped with the latest technology and machinery to enable {Company Name} to offer a wider range of metal fabrication services, including laser cutting, CNC machining, welding, forming, and more. This will allow the company to take on larger and more complex projects while maintaining its high standards of quality and precision.In addition to expanding its manufacturing capabilities, {Company Name} also plans to invest in its workforce by hiring and training skilled professionals to join its team. The company recognizes the importance of having a highly skilled and experienced workforce to deliver top-notch metal fabrication solutions, and is committed to providing the necessary resources and training to support its employees' growth and development.The expansion plans will not only benefit {Company Name} and its clients, but also the local community by creating new job opportunities and contributing to the growth and development of the region's manufacturing industry. {Company Name} is dedicated to being a responsible corporate citizen and is committed to giving back to the community in which it operates.{Company Name} is excited about the upcoming expansion and is confident that it will enable the company to better serve its clients and meet the evolving needs of the market. The company's leadership is optimistic about the future and is looking forward to the opportunities and challenges that come with the expansion.As a leading industrial metal fabrication company, {Company Name} is committed to delivering the highest quality products and services to its clients. The company's expansion plans are a testament to its dedication to excellence and its commitment to staying at the forefront of the industry.With its new manufacturing facility and expanded capabilities, {Company Name} is poised to continue its success and further establish itself as a trusted partner for custom metal fabrication solutions. The company's clients can look forward to even greater possibilities for their projects as {Company Name} continues to raise the bar for excellence in the metal fabrication industry.

Custom Steel Tube Fabrication: Everything You Need to Know

Steel Tube Fabrication Company Excels in Delivering High-Quality ProductsSteel Tube Fabrication Company is a leading manufacturer and distributor of high-quality steel tubes and customized metal fabrication solutions. The company has been in the industry for over two decades and has established a strong reputation for delivering superior products and services to its clients across a wide range of industries.With state-of-the-art facilities and a team of skilled professionals, the Steel Tube Fabrication Company has excelled in meeting the diverse needs of its customers. From small-scale businesses to large corporations, the company prides itself on its ability to tailor its products and services to meet the specific requirements of each client.The company's dedication to quality and customer satisfaction has been a driving force behind its success. By investing in advanced technology and adhering to strict quality control measures, Steel Tube Fabrication Company has consistently delivered products that meet and exceed industry standards.One of the key factors that sets Steel Tube Fabrication Company apart from its competitors is its commitment to innovation. The company continuously seeks out new technologies and processes to improve its manufacturing capabilities and expand its product offerings. This forward-thinking approach has allowed Steel Tube Fabrication Company to stay ahead of the curve and provide its clients with cutting-edge solutions that address their evolving needs.Furthermore, the company's team of engineers and technicians are highly skilled and experienced in working with various types of metals, including stainless steel, carbon steel, and aluminum. This expertise, combined with the company's advanced machinery and equipment, enables Steel Tube Fabrication Company to produce a wide range of custom products, from precision-cut steel tubes to complex metal components.Steel Tube Fabrication Company also takes pride in its commitment to sustainability and environmental responsibility. The company has implemented environmentally friendly practices throughout its operations, including the use of recyclable materials and energy-efficient processes. Additionally, the company actively seeks out ways to reduce waste and minimize its environmental footprint, further demonstrating its dedication to being a responsible corporate citizen.As a testament to its dedication to excellence, Steel Tube Fabrication Company has received numerous accolades and certifications for its outstanding performance in the industry. These accolades are a testament to the company's unwavering commitment to quality, innovation, and customer satisfaction.In addition to its manufacturing capabilities, Steel Tube Fabrication Company also offers a range of value-added services to its clients. These services include design assistance, prototyping, and project management, which allow clients to streamline their production processes and bring their projects to fruition more efficiently.Overall, Steel Tube Fabrication Company has proven itself to be a reliable and trusted partner for businesses seeking superior steel tubing and custom metal fabrication solutions. With its unwavering commitment to quality, innovation, and customer satisfaction, the company continues to set the standard for excellence in the industry.If your business is in need of high-quality steel tubes or custom metal fabrication services, Steel Tube Fabrication Company is the partner you can rely on to deliver exceptional results. Contact them today to learn more about their products and services and how they can help meet your specific needs. With their expertise and dedication to excellence, you can trust Steel Tube Fabrication Company to be your go-to source for all your steel tubing and metal fabrication needs.

US Manufacturer Launches High-Quality Precision Metal Fabrication Services" can be rewritten as "New High-Quality Precision Metal Fabrication Services Now Available in the US.

Precision Fabrications, a leading manufacturing company, is making headlines with its cutting-edge technologies and innovative solutions in the industry. With a strong commitment to quality and customer satisfaction, Precision Fabrications continues to excel in delivering exceptional products and services to its clients worldwide.Established several decades ago, Precision Fabrications has evolved into a global powerhouse in the manufacturing sector. Specializing in the production of precision components and fabricated metal products, the company has garnered a reputation for its expertise, reliability, and attention to detail. With state-of-the-art facilities and a highly skilled workforce, Precision Fabrications is well-equipped to meet the ever-growing demands of its diverse clientele.One of the key strengths of Precision Fabrications lies in its extensive range of capabilities. The company possesses a wide variety of machining and fabrication equipment, allowing it to produce intricate components with utmost precision. From CNC machining and turning to welding and assembly, Precision Fabrications offers comprehensive solutions tailored to meet the unique needs of each client. By combining advanced manufacturing techniques with rigorous quality control measures, the company ensures that every product leaving its facility is of the highest standard.Precision Fabrications serves clients across diverse sectors, including aerospace, automotive, medical, and energy. By catering to such diverse industries, the company has gained invaluable experience in navigating complex manufacturing challenges and delivering solutions that exceed expectations. Its commitment to continuous improvement and investment in research and development have enabled Precision Fabrications to stay ahead of the curve, offering cutting-edge technologies and innovative solutions that keep its clients at the forefront of their respective industries.In addition to its technical expertise, Precision Fabrications places great emphasis on building strong and lasting relationships with its clients. The company recognizes that open communication and collaboration are crucial to ensuring successful partnerships. By actively engaging with clients from project inception to completion, Precision Fabrications is able to fully understand their needs and develop customized solutions that address their specific requirements. This client-focused approach has earned the company a solid reputation for its reliability and ability to deliver on time and within budget.Precision Fabrications also prides itself on its commitment to sustainability and environmental responsibility. The company actively seeks ways to minimize its ecological footprint through efficient use of resources, waste reduction, and recycling initiatives. By implementing eco-friendly practices throughout its operations, Precision Fabrications not only contributes to a greener planet but also demonstrates its commitment to corporate social responsibility.Looking towards the future, Precision Fabrications remains driven by a strong vision to be at the forefront of technological advancements in the manufacturing industry. The company continues to invest in research and development, exploring emerging technologies such as additive manufacturing and automation to further enhance its capabilities. By embracing innovation and staying ahead of industry trends, Precision Fabrications aims to provide its clients with cutting-edge solutions that drive their success in an ever-evolving global market.In conclusion, Precision Fabrications is a leading manufacturing company that has established itself as a trusted partner for clients worldwide. With its commitment to quality, technical expertise, and customer satisfaction, the company continues to deliver exceptional products and services across diverse industries. As it remains dedicated to innovation and sustainability, Precision Fabrications is poised to shape the future of the manufacturing sector, setting new industry standards and raising the bar for excellence.

Optimize Production Efficiency with Sheet Metal Laser Cutting Service

article:Sheet Metal Laser Cutting ServiceSheet Metal Laser Cutting Service, the latest addition to the manufacturing industry, has drastically revolutionized the way metal products are fabricated, and it has become one of the most preferred and reliable methods for cutting and shaping metal. With the advancement in technology, laser cutting has become an affordable and efficient way for businesses to cut and shape their products. The process involves directing a concentrated beam of light at a metal surface, melting or vaporizing the material and leaving a precise, clean cut.The laser cutting technology has been in use since the 1970s, but the process has only recently gained popularity in the manufacturing industry. Prior to this, traditional methods such as sawing, drilling, and punching were used to cut and shape metal. However, these methods caused a lot of wear and tear on the material, leaving rough edges and requiring more finishing work after the cut. Laser cutting has revolutionized the industry by providing businesses with a precision cutting and shaping technique.Sheet Metal Laser Cutting Service is a company that has taken this technology to the next level, with its years of experience and a team of skilled professionals. The company is located in an industrial park in a metropolitan city, equipped with modern, state-of-the-art facilities that allow them to execute orders accurately and efficiently. Sheet Metal Laser Cutting Service takes pride in delivering high-quality metal fabrication services, and they have been successful in providing reliability and affordability to their clients.Sheet Metal Laser Cutting Service offers a wide range of services, including laser cutting of various metals such as aluminum, steel, and stainless steel. The company specializes in customized designs and shapes, and their laser-cut metal products range from metals for transportation, agricultural parts, electronic enclosures, to decorative accents, and customized parts. The precision of the laser cutting process enables the company to produce intricate shapes and designs that are difficult to achieve with traditional manufacturing techniques. They have a team of skilled designers and engineers who work closely with their clients, ensuring that their clients receive the perfect metal product they require.Moreover, Sheet Metal Laser Cutting Service uses the latest technology and equipment to ensure that their clients receive top-notch quality metal products. They have high-powered lasers that are capable of cutting metals of up to 1-inch thickness. The company also has a variety of software programs that enable them to customize and optimize cutting designs, resulting in minimal wastage of materials.The company has an elaborate quality assurance process that ensures they deliver high-quality metal products to their clients. They have strict quality standards in place, with every material goes through a rigorous inspection process to confirm that it meets the client's exact specifications. The company is also committed to ensuring that it delivers products within the specified timeline, and they have a fast turnaround time for orders, ensuring that their clients receive their products promptly.With the commitment to delivering high-quality metal products, reliability, and affordability, Sheet Metal Laser Cutting Service has become one of the preferred choices for businesses in various industries. They have a team of skilled professionals who work tirelessly to ensure the best services for their clients. The company has successfully maintained client satisfaction through the high quality of its metal products and prompt delivery services. In addition, Sheet Metal Laser Cutting Service has competitive pricing, ensuring that their services are affordable for all businesses.In conclusion, Sheet Metal Laser Cutting Service offers high-quality metal fabrication services that have revolutionized the manufacturing industry. With the latest technologies and equipment, the company has a competitive edge in the market and is renowned for timely delivery, reliability, and affordability. The company has set high standards in the industry and has established itself as a reliable service provider. It's an ideal place to seek out for all your metal fabrication requirements.

Plate Cutting Services: A Guide to Laser Technology

Laser Plate Cutting: Revolutionizing Manufacturing ProcessesIn today's fast-paced manufacturing industry, precision and efficiency are key factors in staying ahead of the competition. Companies are constantly on the lookout for innovative technologies that can streamline their production processes and improve the quality of their products. One such technology that has been making waves in the industry is laser plate cutting.Laser plate cutting is a cutting-edge technology that uses a high-powered laser to cut through metal plates with incredible precision and speed. This method of cutting has revolutionized the manufacturing industry, allowing companies to produce intricate and complex metal parts with ease.One company at the forefront of this technology is {Company Name}. They have been leading the way in laser plate cutting services, offering a wide range of cutting capabilities to meet the needs of various industries. Using state-of-the-art laser cutting machines, {Company Name} has been able to provide high-quality, precise cuts on a wide variety of materials, including stainless steel, aluminum, and titanium.With their extensive experience and expertise in laser cutting, {Company Name} has become a trusted partner for many companies looking to outsource their cutting needs. The benefits of laser plate cutting are numerous, including faster production times, lower costs, and the ability to produce complex designs that would be difficult to achieve with traditional cutting methods.{Company Name} has also invested heavily in their facilities and equipment, ensuring that they are always at the cutting edge of technology. They have a team of highly skilled technicians who are trained to operate the laser cutting machines with precision and accuracy, ensuring that each cut meets the highest standards of quality.In addition to their cutting services, {Company Name} also offers design and engineering support to their clients, helping them to optimize their designs for laser cutting and maximize the efficiency of the manufacturing process. This level of support and expertise has made {Company Name} a preferred choice for many companies in need of precision laser cutting services.One of the key advantages of laser plate cutting is its ability to produce clean, burr-free cuts with minimal material waste. This is especially important for companies looking to reduce production costs and improve the overall quality of their products. By choosing laser cutting services from {Company Name}, companies can benefit from these advantages and stay ahead of the competition.The versatility of laser cutting also allows companies to produce a wide range of products, from simple components to complex parts with intricate designs. This flexibility is a major advantage for manufacturers looking to diversify their product offerings and explore new opportunities in the market.As the demand for high-quality, precision-cut metal parts continues to grow, the importance of laser plate cutting services cannot be understated. Companies that invest in this technology can benefit from faster production times, lower costs, and a competitive edge in the market.In conclusion, laser plate cutting has emerged as a game-changing technology in the manufacturing industry, offering a wide range of benefits to companies looking to improve their production processes and stay ahead of the competition. With their expertise and cutting-edge technology, {Company Name} has positioned itself as a leading provider of laser cutting services, helping companies across various industries achieve their manufacturing goals with precision and efficiency.

Demand for High-Quality Elbow Fittings Increases in Construction Industry

In the world of plumbing and construction, stainless steel is an essential material that has earned its reputation for its durability, strength, and resistance to corrosion. One of the primary components of plumbing systems that use stainless steel pipes is the stainless steel elbow, which is indispensable in redirecting the flow of fluids through the system.One of the leading manufacturers of stainless steel elbows in the industry is [Company name], a company that has cemented its place as a reliable and innovative manufacturer of plumbing fittings. The company has been in operation for over {number of years} years and has earned a reputation for maintaining the highest standards of quality in all its products.[Company name] manufactures various types of stainless steel elbows that are designed, developed, and manufactured to meet the diverse needs of the plumbing and construction industries. The company uses state-of-the-art technology, coupled with high-quality raw materials, to create durable and functional stainless steel elbows that are ideal for a wide range of applications.One of the standout features of [Company name]'s stainless steel elbows is their ability to withstand high-pressure environments. This is because the company uses high-grade stainless steel that has been engineered to maintain its structural integrity even under intense pressure. As a result, their products are ideal for use in systems that deal with corrosive fluids, high-temperature environments, and other challenging conditions.Additionally, [Company name]'s stainless steel elbows exhibit excellent resistance to a wide range of chemicals, ensuring that they can be used in an array of plumbing applications. This feature makes their products a popular choice for use in industries such as pharmaceuticals, food and beverage, and chemical production, among others.[Company name]'s team of skilled and experienced professionals is committed to ensuring that their products meet the highest standards of quality and safety. The company adheres to stringent quality control measures, from sourcing raw materials to the finished product's final inspection, to ensure that their stainless steel elbows are of the highest quality possible.The company's customer-centric approach has earned them a loyal customer base, with clients singling out their exceptional customer service experience. [Company name] provides comprehensive support to its customers, from initial product recommendations to after-sales support.In summary, [Company name] is a leading manufacturer of high-quality stainless steel elbows that are engineered to meet the highest standards of quality, durability, and functionality. Their products are ideal for use in a wide range of plumbing applications and are designed to withstand harsh environments, high-pressure systems, and corrosive fluids. By maintaining excellent customer service standards, [Company name] has earned its place as a trusted and reliable plumbing fittings manufacturer in the industry.

Discover a Wide Range of Bending Products and Services on Ferret.com.au

CNC Bending Service: The Future of Metal FabricationMetal fabrication has come a long way since the days of manual hand-operated machines, where the process of metal bending was labor-intensive and required skilled craftsmen. Today, computer numerical control (CNC) technology has revolutionized the manufacturing industry, making it faster, more efficient, and highly accurate.What is CNC Bending?CNC Bending is a process of metal forming that utilizes computer-controlled machines to create precise and complex bends in sheet metal and other materials. CNC machines can perform multiple bends in a single cycle, and they are capable of producing large quantities of parts with minimal operator intervention.The Advantages of CNC BendingCNC metal bending offers several advantages over traditional metal forming methods, including:1. High precision: CNC machines are highly accurate and can produce parts with precise tolerances.2. Rapid production: CNC bending machines can produce parts at a faster rate than manual bending machines, making the process more efficient and cost-effective.3. Versatility: CNC machines can perform multiple bending operations in a single cycle, allowing for the creation of complex shapes and intricate designs.4. Consistency: CNC machines can produce identical parts with the same level of precision every time, ensuring consistency in the final product.5. Reduced waste: CNC machines are programmed to optimize material usage, reducing waste and saving costs.Applications of CNC BendingCNC bending is widely used in various industries, including aerospace, automotive, construction, and electronics. Some of the common applications of CNC bending include:1. Fabrication of metal enclosures, chassis, and panels.2. Production of brackets, frames, and supports.3. Creation of bends in pipes and tubes.4. Manufacturing of complex shapes for medical devices.Choosing the Right CNC Bending Service ProviderWhen it comes to CNC bending services, it’s essential to choose a reliable and experienced service provider that can deliver quality results. Here are some factors to consider when selecting a CNC bending service provider:1. Technology: Choose a provider that uses the latest CNC bending technology and equipment to ensure high precision and efficiency.2. Experience: Look for a provider with years of experience in CNC bending and a proven track record of delivering quality results.3. Capacity: Consider the provider’s capacity to handle your specific project requirements, including materials, specifications, and volume.4. Quality control: Ensure that the provider has a robust quality control process in place to ensure the final product meets your specifications.5. Cost-effectiveness: Compare quotes from multiple providers and choose the one that offers the best value for your money.ConclusionCNC bending is the future of metal fabrication, and its advantages over traditional metal forming methods make it an ideal choice for various industries. By choosing the right CNC bending service provider, you can ensure that your project is produced with high precision, efficiency, and quality. Contact us today to learn more about our CNC bending services!