High-Quality Metal Stamping Services for Your Custom Needs

By:Admin

One company that is at the forefront of providing exceptional custom metal stamping services is {}. With over 20 years of experience in the industry, they have established themselves as a leading provider of precision metal stamping solutions. Their state-of-the-art facilities and advanced technology enable them to deliver high-quality products that meet the needs and specifications of their clients.

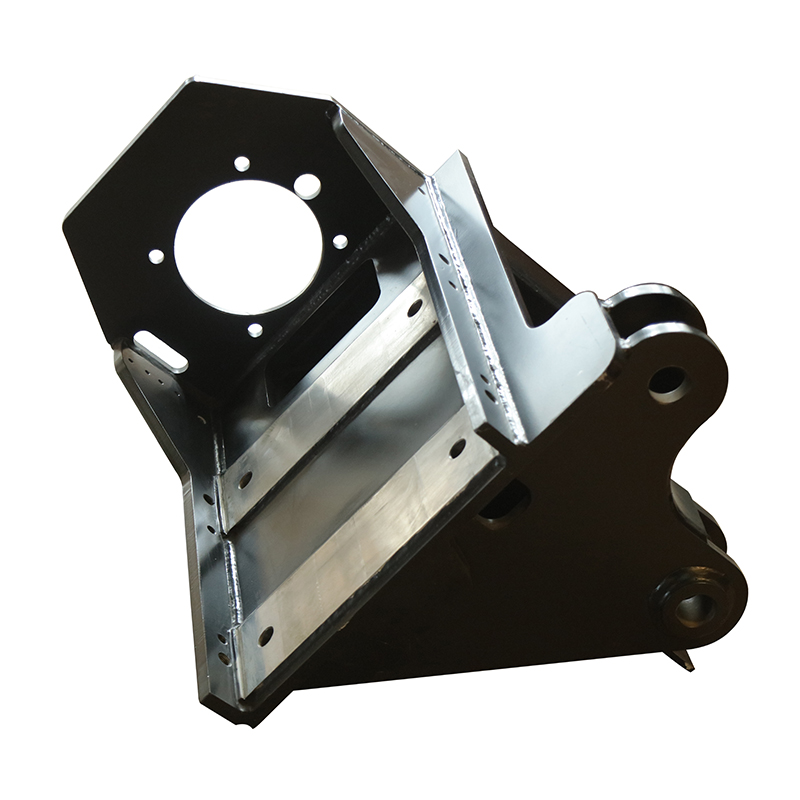

The process of custom metal stamping involves the use of specialized machinery and equipment to cut, bend, and shape metal sheets into the desired form. This requires a high level of precision and expertise to ensure that the resulting parts meet the exact specifications and tolerances required for their intended application. From simple brackets and fasteners to complex automotive components and electronic parts, custom metal stamping services are essential for creating a wide variety of products.

One of the key advantages of custom metal stamping is the ability to produce large quantities of parts with consistent quality and accuracy. This makes it an ideal manufacturing solution for companies looking to streamline their production processes and reduce costs. By working with a reputable custom metal stamping provider like {}, businesses can benefit from the expertise and experience of a team that is dedicated to delivering exceptional results.

Another benefit of custom metal stamping services is the versatility it offers in terms of the materials that can be used. Whether it's aluminum, stainless steel, brass, or other metals, a skilled metal stamping provider can work with a wide range of materials to meet the specific needs of each project. This flexibility allows for the creation of custom parts that are tailored to the unique requirements of each application.

In addition to their expertise in metal stamping, {} also offers a range of additional services to support their clients' needs. This includes tool and die design, prototyping, and assembly services, providing a comprehensive solution for companies looking to bring their product concepts to reality. By offering a full suite of manufacturing capabilities, they are able to streamline the production process and deliver cost-effective solutions for their clients.

The team at {} is committed to delivering the highest standards of quality and customer satisfaction. From small businesses to large corporations, they work closely with each client to understand their specific requirements and provide tailored solutions that meet their needs. With a focus on continuous improvement and innovation, they are constantly seeking new ways to enhance their capabilities and deliver even greater value to their clients.

As the demand for custom metal stamping services continues to grow across a wide range of industries, companies like {} are well-positioned to play a key role in meeting this demand. With their comprehensive capabilities, dedication to quality, and commitment to client satisfaction, they are a trusted partner for businesses seeking precision metal stamping solutions. Whether it's creating custom components for automotive applications or producing specialized parts for electronic devices, {} has the expertise and capability to deliver exceptional results.

Company News & Blog

High-Quality Custom Metal Stampings for Your Project

Custom Metal Stampings has been providing high quality metal stamping services for over 20 years. With a strong focus on precision and customization, the company has earned a reputation for delivering top-notch products to a wide range of industries including automotive, aerospace, electronics, and more.The company’s state-of-the-art facility is equipped with the latest technology and machinery, allowing them to produce custom metal stampings with a high degree of accuracy and consistency. Their team of skilled engineers and technicians work closely with clients to understand their specific requirements and develop tailored solutions to meet their exact needs.Custom Metal Stampings offers a wide range of materials including steel, aluminum, copper, and brass, as well as various finishes and coatings to ensure that their products meet the highest standards of quality and performance. Whether it’s a small batch of prototype parts or a large-scale production run, the company is able to handle projects of any size with efficiency and precision.In addition to their metal stamping services, Custom Metal Stampings also provides a range of secondary operations including deburring, tapping, welding, and assembly to offer a comprehensive solution for their customers. This allows them to deliver finished components that are ready for use right out of the box, saving their clients time and money in the production process.One of the key strengths of Custom Metal Stampings is their ability to work closely with clients from the initial concept and design phase all the way through to production and delivery. This collaborative approach enables them to provide customized solutions that are tailored to each client’s unique specifications and requirements, ensuring that the end product meets their exact needs and expectations.The company is dedicated to continuous improvement and invests heavily in research and development to stay at the forefront of the industry. This commitment to innovation has enabled Custom Metal Stampings to develop advanced stamping techniques and processes that deliver superior results for their clients, setting them apart as a leader in the metal stamping industry.Custom Metal Stampings also places a strong emphasis on quality control and assurance, with a rigorous inspection and testing process in place to ensure that all products meet the highest standards of excellence. Their strict adherence to quality standards and regulatory requirements gives their customers the confidence that they are receiving top-quality products that will perform reliably in their applications.With their unwavering commitment to excellence, Custom Metal Stampings has built a strong and loyal customer base, earning a reputation as a trusted partner for metal stamping solutions. The company’s dedication to quality, precision, and customization has made them a preferred choice for a wide range of industries, and they continue to expand their capabilities and offerings to meet the evolving needs of their clients.In conclusion, Custom Metal Stampings is a leading provider of customized metal stamping solutions, with a strong focus on precision, quality, and customer satisfaction. With their advanced technology, skilled team, and dedication to excellence, they have established themselves as a trusted partner for clients across various industries, delivering top-notch products that meet the highest standards of performance and reliability.

Top Tips for Precision CNC Metal Cutting

CNC Metal Cutting Technology Revolutionizes Manufacturing at []In today's fast-paced manufacturing industry, precision and efficiency are key factors in success. With the advent of CNC metal cutting technology, manufacturers are now able to produce high-quality and complex metal components with ease and accuracy. This technology has revolutionized the way metal parts are fabricated, offering a wide range of benefits for companies looking to enhance their productivity and performance.CNC metal cutting, also known as computer numerical control metal cutting, is a modern manufacturing process that utilizes computer-controlled machines to accurately and efficiently cut and shape metal materials. This technology allows for precise and repeatable machining operations, resulting in high-quality metal components with tight tolerances and smooth finishes. By utilizing advanced computer-aided design (CAD) and computer-aided manufacturing (CAM) software, manufacturers can create detailed and intricate metal parts that meet the exact specifications of their customers.For [], the integration of CNC metal cutting technology has been a game-changer in their manufacturing operations. With an extensive background in metal fabrication, they have embraced CNC metal cutting as a way to stay ahead of the competition and meet the growing demands of their customers. By investing in state-of-the-art CNC machines and training their staff on the latest cutting techniques, [] has been able to expand their capabilities and offer a wider range of metal cutting services to their clients.One of the key advantages of CNC metal cutting technology is its ability to streamline the production process and reduce production time. Traditional metal cutting methods, such as manual milling and turning, are time-consuming and often prone to human error. With CNC metal cutting, the entire process is automated and controlled by the computer, leading to faster and more efficient machining operations. This not only results in quicker turnaround times for customers but also allows manufacturers to take on more complex and challenging projects.In addition to improved efficiency, CNC metal cutting technology also enables manufacturers to achieve higher levels of precision and accuracy. The computer-controlled machines are capable of performing intricate cuts and shaping operations with minimal error, ensuring that each metal component meets the exact specifications of the design. This level of precision is essential for industries that require tight tolerances and complex geometries, such as aerospace, automotive, and medical device manufacturing.Furthermore, CNC metal cutting technology offers a high degree of versatility, allowing manufacturers to work with a wide range of metal materials, including stainless steel, aluminum, titanium, and exotic alloys. This flexibility enables companies like [] to cater to diverse industry needs and provide custom metal cutting solutions for various applications. Whether it's prototyping a new product or mass-producing metal components, CNC metal cutting technology offers the ability to handle a wide spectrum of projects with ease.With the ongoing advancements in CNC metal cutting technology, the future looks promising for the manufacturing industry. As demand for high-quality metal components continues to grow, companies that embrace this cutting-edge technology will be well-positioned to thrive in an increasingly competitive marketplace. [] is a prime example of a company that has leveraged CNC metal cutting to elevate its manufacturing capabilities and deliver exceptional results to its customers.As CNC metal cutting technology becomes more accessible and cost-effective, it's expected that more manufacturers will adopt this innovative approach to metal fabrication. With its unmatched precision, efficiency, and versatility, CNC metal cutting has truly revolutionized the way metal parts are produced, setting a new standard for excellence in the manufacturing industry. As the industry continues to evolve, companies like [] will be at the forefront of this technological revolution, driving innovation and delivering superior metal cutting solutions to their clients.

Sheet Metal Manufacturers: Everything You Need to Know

Sheet metal manufacturing is an essential process in several industries, making it a common requirement for diverse businesses. The process includes cutting, bending, and assembling different types of metals to create finished products. Today, we will be discussing Sheet Metal Prototype Services, an important aspect of sheet metal manufacturing.Sheet metal prototype services refer to the creation of a sample or model of a finished product before full-scale production begins. It allows manufacturers to test and refine their designs before producing them in large quantities. This process is especially crucial for complex products that require several intricate details to come together.Several Sheet Metal Manufacturers offer Sheet Metal Prototype Services, which is an ideal way to ensure that your finished product is perfect before mass production. Below are some reasons sheet metal prototype services are crucial:1. Cost-EffectiveCreating a sheet metal prototype before full-scale production ensures that any design flaws are caught earlier and fixed before mass production begins. This strategy helps to avoid costly redesigns and modifications after mass production has already started. With sheet metal prototype services, you can avoid costly mistakes and achieve the perfect finished product without overspending.2. Enhanced DesignsWith sheet metal prototype services, manufacturers can make design changes to the product in real-time. This approach allows for better, improved designs, and ensures that the final product meets customers' needs and preferences. Additionally, collaborating with Sheet Metal Prototype Services experts helps to build trust by clearly communicating design ideas and ensuring that everyone is on the same page.3. Saves TimeIn the past, creating a sheet metal prototype would take weeks, waiting for a third-party provider to handle the project. Today, many Sheet Metal Manufacturers offer quick prototype services, ensuring that design changes are made quickly. This process helps reduce the time spent building a product and helps manufacturers to meet project deadlines.4. Customer SatisfactionWith sheet metal prototype services, manufacturers can create products that match the exact specifications and requirements of their customers. Creating a prototype allows the customer to see the product before mass production starts, which fosters better communication and collaboration.In conclusion, Sheet Metal Prototype Services are an essential aspect of sheet metal manufacturing. It offers manufacturers and businesses the ability to test and perfect their designs before starting mass production. By doing so, they can produce cost-effective, high-quality, and customer-centric final products that meet their clients' specific needs. Therefore, if you are a business seeking sheet metal manufacturing services, make sure to choose a manufacturer that offers Sheet Metal Prototype Services to ensure the perfect finished product.

Latest Standard Release for High-Precision Plasma, Slope CNC, and Longmen Laser Cutting Machines by Manufacturing Expert

Title: Unleashing the Power of High Precision Laser Cutting for Unparalleled AccuracyIntroduction:In the realm of manufacturing and fabrication, precision is paramount. Industries across the globe rely on cutting-edge technologies to achieve unmatched accuracy and superior quality. Among these technologies, high precision laser cutting has emerged as a game-changer. In this blog, we will delve into the world of high precision laser cutting machines and explore their limitless potential in delivering top-notch results. With a specific focus on CNC high-precision plasma cutting machines, slope CNC cutting machines, and Longmen laser cutting machines, we will analyze the standards set by Kunshan Qiankun Machinery Manufacturing Co., Ltd. in this groundbreaking sector.Unveiling the CNC High-Precision Plasma Cutting Machine:The CNC high-precision plasma cutting machine revolutionizes the cutting process with its exceptional precision and efficiency. Utilizing plasma technology, it allows for high-speed cutting of various materials, ranging from metals to alloys. This innovation is particularly beneficial in industries like automotive, aerospace, and construction, where precision is of the utmost importance. By implementing the high-precision plasma cutting machine, manufacturers can accomplish intricate cuts on thick materials while maintaining clean edges and minimal heat-affected zones. This machine enables intricate designs and complex geometries, providing a remarkable level of customization to cater to unique project requirements.Exploring the Slope CNC Cutting Machine:The slope CNC cutting machine stands out as a game-changer in the field of material processing. It offers a high level of precision and accuracy in beveled cutting applications. Whether it is chamfering, angular shaping, or dependable welding preparation, the slope CNC cutting machine offers remarkable cutting capabilities. This technology effectively eliminates the inconsistencies that arise from manual processes, guaranteeing perfectly angled cuts. With reduced production time, increased efficiency, and improved accuracy, this machine ensures consistent results, thus elevating productivity in the manufacturing industry.Unleashing the Potential of Longmen Laser Cutting Machines:When it comes to Large Scale cutting projects, the Longmen laser cutting machine is an indispensable tool. Renowned for its versatility and flexibility, the Longmen laser cutting technology strikes a perfect balance between precision and speed. It allows for the effortless cutting of large-scale materials, such as sheets, pipes, and beams, providing manufacturers with unlimited creative possibilities. With advanced calibration systems and automated functionality, this machine guarantees pinpoint accuracy, even in complex designs. By implementing the Longmen laser cutting machine, manufacturing companies can achieve exceptional levels of precision, enhancing their competitive edge across multiple industries.Setting the Standard: Kunshan Qiankun Machinery Manufacturing Co., Ltd.:Kunshan Qiankun Machinery Manufacturing Co., Ltd. has been at the forefront of revolutionizing the laser cutting industry. With its unwavering commitment to cutting-edge technology and superior manufacturing processes, the company has set unparalleled standards for high precision laser cutting machines. Their CNC high-precision plasma cutting machine, slope CNC cutting machine, and Longmen laser cutting machine exemplify their dedication to precision, quality, and innovation. Built with state-of-the-art components and stringent quality control measures, these machines offer exceptional reliability and precision, making them the ideal choice for companies seeking superior cutting capabilities.Conclusion:High precision laser cutting machines have revolutionized the manufacturing industry, delivering unmatched accuracy and top-quality results. The CNC high-precision plasma cutting machine, slope CNC cutting machine, and Longmen laser cutting machine have all played pivotal roles in enhancing precision, efficiency, and productivity in diverse sectors worldwide. Kunshan Qiankun Machinery Manufacturing Co., Ltd. is at the forefront of this cutting-edge technology, setting new standards with their dedication to excellence. By incorporating high precision laser cutting machines into their processes, manufacturers can unleash the power of accuracy, thereby elevating their businesses to new heights.

Discover Top-quality Bending Products and Services on Ferret.com.au

Are you searching for efficient and reliable CNC bending services for your business needs? Look no further than www.ferret.com.au to cater to all your bending requirements.At www.ferret.com.au, we offer a wide range of bending products and services from leading suppliers in the industry. Our suppliers are reputable and well-established, ensuring that you get the best quality products and services at an affordable price.CNC bending services are a vital component in the manufacturing industry. CNC (Computer Numerical Control) bending service is a highly automated process that reduces human error and increases efficiency. This advanced technology makes it possible to achieve high accuracy and precision in bending metal sheets.Our suppliers use modern CNC bending machines that are versatile and capable of bending different types of metal sheets in a range of sizes and thicknesses. These machines can also bend metal pipes and tubes, making them ideal for different manufacturing applications.CNC bending services offered at www.ferret.com.au include press brake bending, tube bending, and roll bending. Press brake bending is suitable for producing parts in large quantities and is used for both simple and complex bending operations. Tube bending is ideal for creating complex shapes and designs, while roll bending is ideal for producing curved and circular metal parts.We understand the importance of delivering high-quality products and services to our customers. Therefore, our suppliers use only the best materials and processes to ensure that the end product meets or exceeds your expectations.Our suppliers also offer customized CNC bending services to cater to specific needs and requirements. They work closely with customers to ensure that the end product meets their precise specifications. This personalized approach ensures that every customer gets the best possible bending solution for their business.In conclusion, if you require CNC bending services for your manufacturing needs, look no further than www.ferret.com.au. We offer a wide range of bending products and services from reputable and reliable suppliers in the industry. Our suppliers use modern CNC bending machines to provide high-quality products and services that meet or exceed your expectations. Contact us today to get started on your CNC bending project!

Stainless Steel Pipe Welding: Tips and Techniques for a Strong and Durable Connection

Stainless steel pipe welding is a crucial process in the manufacturing of various industrial products. It requires precision and expertise to ensure the highest quality and durability of the final product. With this in mind, {Company} has been leading the way in providing top-notch stainless steel pipe welding services to its clients.{Company} is a renowned name in the industry, known for its expertise in stainless steel fabrication and welding. With over 20 years of experience, the company has established itself as a reliable and trusted partner for businesses across various sectors, including oil and gas, construction, and manufacturing.The company's state-of-the-art facility is equipped with the latest welding technology and machinery, allowing them to handle a wide range of stainless steel pipe welding projects with precision and efficiency. Their team of skilled welders and engineers undergo regular training to stay updated with the latest industry standards and techniques, ensuring that the welding process is carried out with the highest level of expertise and precision.One of {Company}'s key strengths is its ability to cater to custom requirements. They understand that every client has unique needs and specifications, and they work closely with them to ensure that these are met. Whether it's a small-scale project or a large industrial undertaking, {Company} has the capability to deliver exceptional stainless steel pipe welding services tailored to the client's specific requirements.In addition to their technical expertise, {Company} is also committed to upholding the highest standards of quality and safety. They adhere to strict quality control measures throughout the welding process, conducting thorough inspections to ensure that the welded pipes meet the required quality standards. Moreover, the company prioritizes safety in all aspects of their operations, implementing stringent safety protocols to protect their workforce and the environment.{Company} has earned a solid reputation for delivering reliable, high-quality stainless steel pipe welding services within agreed-upon timelines. Their commitment to excellence and customer satisfaction has made them a preferred choice for many businesses looking for seamless and efficient stainless steel pipe welding solutions.Furthermore, the company's dedication to innovation and continuous improvement sets them apart in the industry. They constantly invest in research and development to explore new welding techniques and technologies that can further enhance the quality and efficiency of their services. This proactive approach ensures that their clients benefit from the latest advancements in stainless steel pipe welding, giving them a competitive edge in their respective industries.In conclusion, {Company} is a leading provider of stainless steel pipe welding services, known for its expertise, reliability, and commitment to quality. With a focus on precision, safety, and customer satisfaction, the company continues to set the benchmark for excellence in the industry. Whether it's a complex industrial project or a custom requirement, clients can trust {Company} to deliver exceptional stainless steel pipe welding solutions that meet their needs and exceed their expectations.

Quality Sheet Metal Fabrication Shop

Sheet Metal Fabrication Shop provides high-quality metal fabrication services to a wide range of industries, including automotive, aerospace, construction, and more. With a team of highly skilled technicians and state-of-the-art equipment, the company has established itself as a leader in the metal fabrication industry.The company offers a comprehensive range of services, including laser cutting, CNC punching, bending, welding, and assembly. They are able to work with a variety of materials, including stainless steel, aluminum, and carbon steel, and can accommodate projects of all sizes and complexities.One of the key strengths of Sheet Metal Fabrication Shop is its commitment to quality. The company adheres to strict quality control measures throughout the fabrication process, ensuring that each and every product meets the highest standards. This dedication to quality has earned them a reputation for excellence in the industry and has led to long-standing relationships with many satisfied clients.In addition to their commitment to quality, Sheet Metal Fabrication Shop also places a strong emphasis on customer service. They work closely with each client to understand their specific needs and requirements, and then tailor their services to meet those needs. This level of personalized attention has set them apart from their competitors and has helped them build a loyal customer base.The company has also made significant investments in technology and infrastructure to ensure that they are at the forefront of the industry. Their state-of-the-art equipment allows them to take on a wide variety of projects, from simple prototypes to large-scale production runs. This flexibility has made them a go-to resource for many companies in need of custom metal fabrication solutions.But Sheet Metal Fabrication Shop's commitment to excellence goes beyond just their products and services. They also prioritize environmental sustainability in their operations, striving to minimize their impact on the environment. This includes recycling scrap metal, utilizing energy-efficient equipment, and implementing processes to reduce waste.With a strong foundation built on quality, customer service, and innovation, Sheet Metal Fabrication Shop is well-positioned for continued success in the industry. They have proven themselves as a reliable partner for companies in need of metal fabrication services and will continue to provide high-quality solutions for years to come.As Sheet Metal Fabrication Shop looks towards the future, they are exploring new opportunities for growth and expansion. They are constantly seeking ways to improve their operations and services, whether through new technology, expanded capabilities, or strategic partnerships. This drive for continual improvement will no doubt solidify their position as a leader in the metal fabrication industry.The company is also committed to giving back to the community. They are involved in various charitable initiatives and are dedicated to supporting local organizations and causes. This commitment to social responsibility reflects their values and further solidifies their reputation as a company that cares about more than just the bottom line.In conclusion, Sheet Metal Fabrication Shop has established itself as a trusted provider of metal fabrication services, known for their commitment to quality, customer service, and innovation. With a solid foundation and a drive for continual improvement, they are well-positioned for continued success in the industry. Their dedication to excellence, environmental sustainability, and community involvement sets them apart as a company that not only delivers top-notch products and services but also values integrity and responsibility.

New Standards for Advanced Cutting Machinery Released by Kunshan Manufacturer

Kunshan Qiankun Machinery Manufacturing Co., Ltd. has recently released their new line of CNC high-precision plasma cutting machines, slope CNC cutting machines, and Longmen laser cutting machines. These machines are designed to offer high precision laser cutting, making them a popular choice for industrial and commercial applications.Over the years, laser cutting machines have become a popular choice for cutting, engraving, and marking various materials like metal, wood, and plastic. As advancements continue to be made in laser cutting technology, the demand for high precision laser cutting machines has significantly increased.This is where Kunshan Qiankun Machinery Manufacturing Co., Ltd. comes in. They specialize in providing advanced CNC high-precision plasma cutting machines, slope CNC cutting machines, and Longmen laser cutting machines, which offer incredible accuracy and precision on a wide range of materials.Their CNC high-precision plasma cutting machine uses plasma to precisely cut through metal sheets, making it an excellent choice for manufacturers who need to cut thicker materials. It combines a precise cutting head with a powerful plasma generator, which can easily cut through thick sheets of metal quickly and precisely.The slope CNC cutting machine is another innovative solution that has been designed for accuracy and precision. This machine is suitable for cutting materials at different angles, making it a great choice for industries such as automotive, aerospace, and construction.And then there's the Longmen laser cutting machine, which is ideal for manufacturers that require high precision cutting on large materials. This machine has been designed to efficiently and precisely cut large material sheets with minimal errors, saving manufacturers time and money.These machines come with advanced features such as automatic edge detection, which ensures that the cut is made precisely, with no deviations. Additionally, these machines are built to withstand the rigors of industrial use, ensuring you can rely on them for long periods with minimal maintenance.In conclusion, the CNC high-precision plasma cutting machine, slope CNC cutting machine, and Longmen laser cutting machine from Kunshan Qiankun Machinery Manufacturing Co., Ltd. are excellent choices for manufacturers that demand precision and accuracy in their laser cutting operations.With advanced features, durable construction, and high cutting speeds, these machines are ideal for industries that require high precision laser cutting, including automotive, aerospace, construction, and manufacturing, among others. So if you're looking for an innovative solution for your laser cutting needs, Kunshan Qiankun Machinery Manufacturing Co., Ltd. has got you covered!

Top Structural Steel Manufacturer Provides Quality Products for Construction Projects

Structural Steel Manufacturer, a leading steel fabrication company, has recently announced its expansion plans and commitment to provide high-quality steel products for construction and infrastructure projects.Established in 1990, Structural Steel Manufacturer has been at the forefront of the steel industry, specializing in the production of structural steel components for commercial, industrial, and residential projects. With state-of-the-art manufacturing facilities and a team of experienced engineers and technicians, the company has built a solid reputation for delivering reliable and cost-effective steel solutions.In a recent statement, the company revealed its plans for expansion to meet the growing demand for steel products in the construction and infrastructure sectors. With the increasing number of development projects and the need for high-quality steel components, Structural Steel Manufacturer aims to enhance its production capacity and capabilities to cater to the evolving market requirements.The expansion plans include the addition of new manufacturing equipment and facilities, as well as the implementation of advanced technologies to improve production processes and efficiency. By investing in these initiatives, the company aims to streamline its operations and increase its overall output to better serve its clients and partners.Furthermore, Structural Steel Manufacturer is committed to maintaining its stringent quality control standards, ensuring that all its steel products meet the highest industry specifications and standards. The company's dedication to quality has been a key factor in its success, and it remains a top priority as it expands its operations.In addition to its expansion plans, Structural Steel Manufacturer is also focused on sustainability and environmental responsibility. The company recognizes the importance of minimizing its environmental impact and has adopted various eco-friendly practices in its manufacturing processes. From utilizing energy-efficient technologies to implementing recycling initiatives, the company is committed to operating in a sustainable manner and reducing its carbon footprint.Furthermore, as part of its commitment to excellence, Structural Steel Manufacturer continues to invest in its workforce, providing ongoing training and development opportunities for its employees. By nurturing a skilled and dedicated team, the company can ensure the highest standards of workmanship and customer service.As the construction and infrastructure industries continue to evolve, the demand for high-quality steel products is expected to rise. Structural Steel Manufacturer is well-positioned to address this demand with its expansion plans and unwavering commitment to quality and sustainability.The company's dedication to innovation, sustainability, and excellence has enabled it to establish itself as a trusted partner for construction and infrastructure projects. With its expansion plans and ongoing commitment to quality, Structural Steel Manufacturer is poised to continue its success and contribute to the advancement of the steel industry.