Expert Metal Bending Services for Your Industrial Needs

By:Admin

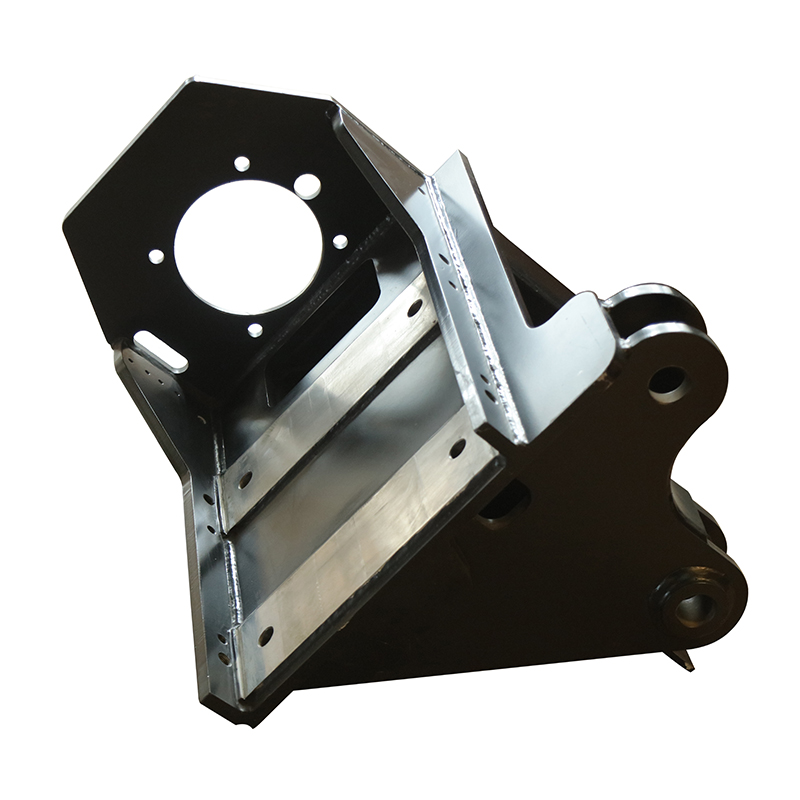

Metal Bending Services specializes in a variety of metal bending techniques, including press brake bending, roll bending, and stretch bending. Their state-of-the-art facilities are equipped with the latest technology and machinery, allowing them to handle even the most complex bending projects with ease. From small batch prototyping to large-scale production runs, Metal Bending Services has the capability to meet the diverse needs of their clients.

One of the key differentiators of Metal Bending Services is their commitment to continuous improvement and innovation. The company invests heavily in research and development to stay ahead of industry trends and technological advancements. This proactive approach has allowed Metal Bending Services to offer cutting-edge solutions to their clients, ensuring that they always receive the highest quality products and services.

In addition to their technical expertise, Metal Bending Services takes great pride in their customer-centric approach. The company works closely with each client to understand their specific needs and requirements, providing customized solutions that meet and exceed expectations. Their team of highly skilled engineers and technicians are dedicated to delivering exceptional results, and their attention to detail ensures that every project is executed with the utmost precision.

Metal Bending Services also places a strong emphasis on efficiency and cost-effectiveness. By leveraging their expertise and resources, the company is able to streamline production processes and optimize workflow, ultimately reducing lead times and production costs for their clients. This focus on operational excellence has made Metal Bending Services a preferred partner for businesses looking to enhance their manufacturing capabilities without compromising on quality.

Furthermore, Metal Bending Services is committed to sustainability and environmental responsibility. The company adheres to strict environmental standards and regulations, implementing eco-friendly practices throughout their operations. From waste reduction and recycling to energy conservation, Metal Bending Services strives to minimize their environmental footprint while delivering top-notch metal bending solutions.

As Metal Bending Services continues to grow and expand their reach, they remain dedicated to upholding their core values of quality, innovation, customer satisfaction, and sustainability. With their proven track record of success and their unwavering commitment to excellence, Metal Bending Services is poised to remain a leader in the metal bending industry for years to come.

With their extensive experience, cutting-edge technology, and customer-focused approach, Metal Bending Services is well-positioned to meet the evolving needs of the manufacturing industry. Whether it's a complex metal shaping project or a high-volume production run, clients can rely on Metal Bending Services to deliver superior results with efficiency, precision, and unmatched quality.

Company News & Blog

Professional Steel Welding Services for Your Project Needs

Steel Welding Service, a leading provider of welding and fabrication services, is pleased to announce the launch of their newest location in the heart of the industrial district. With over 20 years of experience in the welding industry, Steel Welding Service has established itself as a trusted partner for businesses in need of high-quality welding and fabrication solutions.The new facility is equipped with state-of-the-art machinery and a team of highly skilled welders and fabricators, allowing Steel Welding Service to meet the increasing demand for their services in the area. The company's commitment to excellence and customer satisfaction has been a driving force behind their expansion, and the new location will enable them to better serve their growing client base."We are thrilled to open our newest location in the industrial district," said the CEO of Steel Welding Service. "This expansion is a testament to our dedication to providing top-notch welding and fabrication services to our clients. We are excited to bring our expertise and craftsmanship to the businesses in this area and look forward to fostering new partnerships."Steel Welding Service offers a wide range of welding and fabrication services, including MIG welding, TIG welding, stainless steel fabrication, aluminum fabrication, custom metal fabrication, and more. Their team of experts is capable of handling projects of all sizes, from small prototypes to large-scale industrial applications. By combining cutting-edge technology with traditional craftsmanship, Steel Welding Service ensures that each project is completed with precision and according to the highest standards of quality.In addition to their welding and fabrication capabilities, Steel Welding Service also offers on-site welding and fabrication services, allowing clients to receive their services directly at their location. This convenience has been instrumental in their success, as it enables businesses to minimize downtime and improve efficiency by having their welding and fabrication needs met on-site.The company's dedication to exceptional customer service and satisfaction has earned them a stellar reputation in the industry. Steel Welding Service has built long-lasting relationships with their clients by consistently delivering superior results and exceeding expectations. Their commitment to quality and reliability has set them apart as a leader in the welding and fabrication space.With the opening of their new location, Steel Welding Service is poised to further elevate their position as a trusted provider of welding and fabrication solutions. The company's expansion represents a significant milestone in their growth, and they are eager to extend their services to more businesses in the industrial district and beyond.As they continue to expand, Steel Welding Service remains focused on upholding their core values of integrity, professionalism, and excellence. Their team is dedicated to staying at the forefront of industry advancements and delivering innovative solutions that meet the evolving needs of their clients. With their new location, Steel Welding Service is well-equipped to continue exceeding expectations and setting new standards for welding and fabrication services.For businesses in need of top-quality welding and fabrication services, Steel Welding Service stands as a reliable and capable partner. Their commitment to excellence, combined with their extensive experience and expertise, makes them the go-to choice for businesses looking for superior welding and fabrication solutions. As they embark on this new chapter of growth, Steel Welding Service is fully prepared to meet the increasing demand for their services and provide unmatched craftsmanship to their clients.

High-Quality Custom Metal Stampings for Various Industries

Custom Metal Stampings (CMS) is a leading company in the metal stamping industry, providing high-quality precision metal stamping services to a wide range of industries. With over 20 years of experience, CMS has established itself as a trusted partner for businesses seeking reliable and cost-effective metal stamping solutions.At CMS, our team of skilled professionals is committed to delivering the highest quality products and services to our customers. We specialize in the production of custom metal stampings, utilizing advanced technologies and equipment to meet the unique needs of each client. Whether it's a simple component or a complex design, CMS has the capabilities to deliver precision metal stampings that meet or exceed industry standards.Our state-of-the-art facilities are equipped with the latest metal stamping equipment, allowing us to produce a wide variety of metal parts with tight tolerances and intricate designs. We have the expertise to work with a range of materials, including stainless steel, aluminum, brass, and copper, ensuring that we can accommodate the needs of diverse industries.In addition to our precision metal stamping capabilities, CMS also offers a range of secondary services, including assembly, plating, and finishing, to provide our customers with comprehensive solutions for their metal stamping needs. Our commitment to excellence and customer satisfaction has earned us a reputation for delivering high-quality products on time and within budget.The success of CMS can be attributed to our dedication to continuous improvement and innovation. We regularly invest in new technologies and processes to enhance our capabilities and stay ahead of industry trends. This commitment to innovation enables us to provide our customers with the latest advancements in metal stamping technology, ensuring that we can meet the evolving needs of their businesses.In the news, CMS is pleased to announce the launch of a new line of custom metal stampings that offers enhanced features and performance for our customers. The new product line has been developed in response to the growing demand for high-quality metal stampings with advanced capabilities, and it reflects our ongoing commitment to innovation and excellence.The new custom metal stampings incorporate the latest advancements in metal stamping technology, including improved precision, durability, and consistency. These enhancements are designed to meet the needs of customers in a wide range of industries, including automotive, aerospace, electronics, and more, where precision and reliability are critical.With the launch of the new product line, CMS is positioned to further solidify its reputation as a leading provider of custom metal stamping solutions. Our continued investment in advanced technologies and processes ensures that we can offer our customers the highest quality products and services, making us a trusted partner for their metal stamping needs."We are excited to introduce our new line of custom metal stampings, which reflects our commitment to delivering innovative and high-quality solutions to our customers," said [Name], CEO of CMS. "With the latest advancements in metal stamping technology, we are confident that our new product line will meet the evolving needs of our customers and provide them with the performance and reliability they expect from CMS."In conclusion, CMS continues to be a leader in the metal stamping industry, providing high-quality precision metal stamping services to a diverse range of industries. With our commitment to excellence, innovation, and customer satisfaction, we are well-positioned to meet the evolving needs of our customers and deliver the highest quality products and services for years to come.

Affordable Metal Cutting Laser - Latest News on Budget-Friendly Options

Title: Pioneering the Metal Cutting Industry: Revolutionary Affordable Laser Technology Disrupts Market NormsIntroduction:In an industry known for its costly equipment and extensive manual labor, a groundbreaking development is set to revolutionize metal cutting processes. A new entrant, hereinafter referred to as the "Company," has launched the market's most affordable and efficient metal cutting laser, poised to transform manufacturing operations globally. This article discusses the key features and benefits of the Cheapest Metal Cutting Laser and highlights the implications of this disruptive innovation.Disrupting Industry Norms:Traditionally, metal cutting operations have demanded substantial financial investments, making them prohibitive for small and medium-sized enterprises. However, the Company's commitment to advancing technology and affordability has revolutionized the market. The Cheapest Metal Cutting Laser disrupts industry norms by offering a cost-effective solution without compromising on efficiency or quality.Unleashing Laser Technology's Potential:The market-leading metal cutting laser represents a significant leap in laser technology, harnessing its potential and delivering exceptional results. Laser cutting processes have been highly valued for their precision and speed, streamlining manufacturing operations across various industries. The Company's innovation not only significantly reduces costs but also ensures optimal performance, making laser cutting accessible to businesses of all sizes.Key Features and Benefits:1. Affordability:The Cheapest Metal Cutting Laser is priced substantially lower than its competitors without compromising on quality or performance. This affordability allows businesses to invest in laser technology, increasing their productivity and expanding their capabilities.2. Enhanced Precision:Advanced laser technology ensures exceptional precision levels, resulting in high-quality, accurate cuts. This precision reduces material wastage, thereby enhancing cost-effectiveness and supporting sustainable manufacturing practices.3. Rapid Cutting Speeds:The Cheapest Metal Cutting Laser boasts impressive cutting speeds, dramatically reducing production time. Shorter processing times translate to increased efficiency and quicker turnaround, enabling businesses to meet growing customer demands while potentially expanding their client base.4. Versatility:With its ability to cut through various metals, including steel, aluminum, copper, and alloys, this cutting-edge technology caters to a wide range of industrial applications. From automotive parts manufacturing to intricate jewelry design, the Cheapest Metal Cutting Laser empowers businesses to explore new opportunities.5. Minimal Downtime:Designed with durability and reliability in mind, the laser tool minimizes downtime due to maintenance and repairs. This results in uninterrupted operations, reducing losses accrued from production halts and maximizing overall productivity.Implications for the Metal Cutting Industry:The introduction of this affordable metal cutting laser marks a pivotal moment in the industry. The accessibility of laser technology to a more extensive range of businesses is expected to yield several significant implications:1. Democratizing Manufacturing:The Cheapest Metal Cutting Laser democratizes the manufacturing industry by bringing laser-cutting capabilities to small and medium-sized enterprises. This broadened access fosters competition, drives innovation, and stimulates overall industry growth.2. Job Creation:As businesses adopt laser technology, there is potential for increased job creation within the metal cutting sector. The integration of advanced machinery necessitates skilled technicians, strengthening the labor market and promoting economic development.3. Sustainability:By minimizing material wastage and optimizing production processes, the Cheapest Metal Cutting Laser contributes to sustainable manufacturing practices. Efficiency gains and reduced energy consumption support eco-friendly policies, aligning industry practices with global demands for environmental responsibility.Conclusion:In this era of technological advancements, the Company has emerged as a game-changer in metal cutting. The introduction of the Cheapest Metal Cutting Laser is set to transform the industry by making laser technology more accessible, significantly reducing costs, and maintaining high precision levels. As more businesses embrace this revolutionary innovation, these affordable and efficient metal cutting lasers have the potential to shape the future of manufacturing, empowering businesses of all sizes to thrive in a highly competitive market.

Expert Welding and Steel Fabrication Services in Rock Springs, WY

and Fabrication, Rock Springs, Wyoming.Rock Springs, Wyoming, is a bustling city, known for its rich natural resources and exceptional manufacturing industries. One such industry that has been thriving in Rock Springs for years is the welding and steel fabrication industry. Welding and steel fabrication are important components of numerous projects, from construction to automotive and aircraft industries. This industry requires skill, precision, and expertise, which is what makes the welding and steel fabrication companies in Rock Springs, Wyoming, stand out from the rest.What is Steel Welding and Fabrication?Steel welding and fabrication refer to the processes of joining metal parts together by heating them to melting points, fusing them together and shaping them into a specific shape, size, and strength. This process is used to create products ranging from simple shapes to complex structures that are used in different industries.Steel welding and fabrication require a high level of skill and knowledge to carry them out effectively. They include various scientific principles such as metallurgy, physics, and thermodynamics, and they involve different welding techniques such as TIG, MIG, and Stick welding, among others.Rock Springs Welding and Steel FabricationThe Welding and Steel Fabrication industry in Rock Springs, Wyoming, is incredibly important to the region's economy. The city has plenty of businesses that specialize in various welding and steel fabrication services, including custom fabrication, structural steel, welding repair, and equipment repair services.One welding and fabrication business in Rock Springs, Wyoming, stands out from the rest due to their exceptional services. The company is located at 531 N Front Street and has been serving the community with welding and steel fabrication services for years.The company offers a complete range of welding and steel fabrication services to both residential and commercial clients. They have a team of highly skilled and experienced welders who are experts in different welding techniques, including TIG, MIG and Stick welding. Additionally, they've invested in advanced equipment to provide fast and efficient services, which is an essential aspect of any welding and fabrication project.Their steel fabrication services are unparalleled. They can design and fabricate a wide range of structural steel products, including stairs, railings, beams, columns, and trusses. Their custom fabrication services are also noteworthy. They can fabricate any steel, aluminum, or stainless-steel product a client may require, ranging from tables, chairs, grills and fire pits, to name a few.One of the things that make this business stand out is their commitment to quality services and their attention to detail. Every project they undertake is treated with the utmost care and precision, ensuring that the final product is of exceptional quality. Their service is known to be reliable, thus demonstrating their dedication to excellent customer service.ConclusionSteel welding and fabrication are essential to the success of numerous industries. In Wyoming, Rock Springs has a thriving welding and steel fabrication industry. Numerous businesses located in Rock Springs specialize in different welding and steel fabrication services, including custom fabrication, repair services, and structural steel products.One company, in particular, stands out from the rest due to their exceptional services, dedication, advanced equipment, and a team of highly skilled, experienced welders - All at an affordable price. These factors differentiate them from other welding and steel fabrication businesses in Rock Springs, Wyoming. If you're in need of high-quality welding and steel fabrication services in the Rock Springs, Wyoming area, reach out to them for a free estimate today.

Professional Sheet Metal Folding Services: Get Precision Results for Your Project

Sheet metal folding services are vital in the manufacturing and construction industries as they allow for the creation of precise and complex sheet metal components. These services are essential for a wide range of industries, including automotive, aerospace, electronics, and architecture. With the advancements in technology, sheet metal folding services have become more efficient and accurate, offering businesses the ability to create high-quality products at a faster pace.{Company Name} is a leading provider of sheet metal folding services, offering a wide range of capabilities to meet the needs of various industries. With state-of-the-art equipment and a team of skilled professionals, {Company Name} is able to produce complex and precise sheet metal components to exact specifications.One of the key benefits of sheet metal folding services is the ability to create components with tight tolerances and complex geometries. This is essential for industries such as aerospace and automotive, where precision is paramount. By using advanced folding techniques and high-quality equipment, {Company Name} is able to produce components that meet the most stringent requirements.In addition to precision, sheet metal folding services also offer the benefit of cost-effectiveness. By utilizing efficient processes and cutting-edge technology, {Company Name} is able to reduce production time and minimize material waste, ultimately leading to cost savings for their clients. This makes sheet metal folding services an attractive option for businesses looking to streamline their manufacturing processes and reduce overall production costs.Furthermore, sheet metal folding services offer versatility in the types of materials that can be used. {Company Name} has the capability to work with a variety of materials, including aluminum, stainless steel, and carbon steel, allowing them to meet the diverse needs of their clients. This versatility is essential for businesses that require components made from different materials for various applications.With the increasing demand for high-quality sheet metal components, {Company Name} has continued to invest in their sheet metal folding capabilities. Their commitment to staying ahead of industry trends and advancements in technology has allowed them to maintain their position as a leader in the sheet metal fabrication industry.{Company Name}'s dedication to quality and customer satisfaction is evident in their approach to sheet metal folding services. They work closely with their clients to understand their specific needs and requirements, ensuring that the final product meets or exceeds expectations. This customer-centered approach has earned them a reputation for delivering reliable and high-quality sheet metal components.As the manufacturing and construction industries continue to evolve, the demand for sheet metal folding services is expected to increase. With their advanced capabilities and commitment to excellence, {Company Name} is well-positioned to meet the growing needs of these industries and continue to provide top-notch sheet metal folding services to their clients.In conclusion, sheet metal folding services are essential for a wide range of industries, and {Company Name} is a leading provider of these services. With their advanced capabilities, commitment to quality, and customer-centered approach, {Company Name} is well-equipped to meet the increasing demand for high-quality sheet metal components. As technology continues to advance, {Company Name} is poised to remain a key player in the sheet metal fabrication industry, delivering efficient and precise sheet metal folding services to their clients.

Discover the Latest Trends in Welding and Metal Fabrication

Title: Advancements in Welding and Metal Fabrication Pioneered by Industry LeaderIntroduction [Company Introduction: Remove brand name][Company Name], a renowned leader in the welding and metal fabrication industry, has consistently set new benchmarks through its innovative solutions and cutting-edge technologies. With a firm dedication towards quality and customer satisfaction, [Company Name] has revolutionized the sector and helped shape modern-day welding and metal fabrication practices. Through its unwavering commitment to excellence, it continues to drive advancements that redefine the industry's landscape.Body:1. History of Welding and Metal Fabrication:Welding and metal fabrication have been integral to human civilization for centuries. From ancient blacksmiths shaping metal to modern-day industries constructing intricate structures, the art of welding and metal fabrication has undergone remarkable transformations. Over time, various techniques and equipment have evolved, allowing for stronger, more durable, and complex welds.2. The Role of [Company Name] in Advancing the Industry:[Company Name] has played a pivotal role in propelling the welding and metal fabrication industry forward through its relentless pursuit of innovation and excellence. By investing in research and development, [Company Name] has introduced groundbreaking techniques and technologies that have redefined the industry's capabilities.3. Cutting-Edge Welding and Metal Fabrication Technologies:[Company Name] has consistently pioneered modern welding and metal fabrication technologies, ensuring enhanced efficiency and precision in various applications. Some notable advancements introduced by [Company Name] include: a. Laser Welding: [Company Name]'s revolutionary laser welding technology enables precise and high-speed welding, minimizing deformation and increasing productivity. The precise control offered by this technique ensures superior quality welds in various materials. b. Robotic Welding: By incorporating robotic welding systems, [Company Name] has revolutionized productivity and accuracy in metal fabrication. These systems offer a level of consistency and repeatability that human operators find hard to match, resulting in impeccable weld quality and increased output. c. CNC Plasma Cutting: [Company Name]'s CNC plasma cutting technology enables precise and efficient metal cutting, ensuring faster turnaround times and reduced material waste. This technology enables intricate designs to be translated flawlessly, expanding the possibilities for creative metal fabrication.4. Advancements in Materials and Metallurgy:[Company Name] has also focused on advancements in materials and metallurgy to cater to evolving industry needs. By harnessing innovative alloys and metals, [Company Name] has expanded the range of possible welding and fabrication applications. This includes developing high-strength materials suitable for demanding environments, as well as alloys specifically tailored for lightweight structures.5. Commitment to Safety and Sustainability:[Company Name] places great emphasis on safety and sustainability in welding and metal fabrication practices. It actively promotes the use of environmentally friendly processes, such as minimization of waste and pollution, as well as the adoption of safe welding procedures. By prioritizing sustainability, [Company Name] ensures a cleaner and greener future for the industry.Conclusion:As a frontrunner in the welding and metal fabrication industry, [Company Name] has consistently pushed the boundaries of what is possible. Through its relentless dedication to innovation, it has redefined the sector with groundbreaking technologies, materials, and safety practices. By setting new benchmarks, [Company Name] continues to shape the future of welding and metal fabrication, ensuring a more efficient, sustainable, and advanced industry for years to come.

How to Weld Stainless Steel to Steel: Tips and Techniques

In a recent development, (company name) has announced the successful welding of stainless steel to steel, a breakthrough that has the potential to revolutionize the manufacturing industry. This achievement is the result of years of research and development, solidifying (company name)’s position as a leader in innovative engineering solutions.The ability to effectively weld stainless steel to steel has long been a challenge for manufacturers. Stainless steel is known for its corrosion resistance and strength, making it a popular choice in a wide range of industries, from automotive to construction. However, welding stainless steel to other materials, such as steel, has proven to be difficult due to the differences in their properties.With this breakthrough, (company name) has overcome these challenges and opened up new possibilities for manufacturers. By being able to weld stainless steel to steel, manufacturers can now create stronger and more durable products, while also reducing costs and complexity in the manufacturing process.The successful welding process developed by (company name) involves a combination of advanced welding techniques and proprietary technologies. This includes the use of specialized equipment and expertise in metallurgy to ensure a strong and reliable bond between the two materials.This achievement is a testament to (company name)’s commitment to pushing the boundaries of what is possible in engineering and manufacturing. The company’s dedication to research and development has allowed them to stay ahead of the curve and provide their customers with cutting-edge solutions to their most pressing challenges.In addition to the technical aspects of this achievement, (company name)’s success in welding stainless steel to steel also highlights their commitment to sustainability. By enabling the use of more durable materials in manufacturing, (company name) is helping to reduce the environmental impact of the products produced by their customers. This is in line with the company’s overall mission to promote sustainable practices and reduce the carbon footprint of the manufacturing industry.The implications of this breakthrough are far-reaching and have the potential to impact a wide range of industries. From automotive components to infrastructure projects, the ability to weld stainless steel to steel will open up new possibilities for designers and engineers, allowing them to create products that are stronger, more durable, and more efficient.This achievement also positions (company name) as a key player in the global manufacturing industry, offering a competitive advantage to their customers and cementing their reputation as a provider of innovative and reliable solutions.Looking ahead, (company name) is committed to further refining and expanding on this breakthrough, with the goal of making the welding of stainless steel to steel even more accessible and cost-effective for manufacturers. With their track record of success and their dedication to pushing the boundaries of what is possible, (company name) is well-positioned to continue leading the way in engineering and manufacturing innovation.In conclusion, the successful welding of stainless steel to steel by (company name) represents a major milestone in the manufacturing industry. This achievement not only demonstrates the company’s technical expertise and commitment to sustainability, but also opens up new possibilities for manufacturers across a wide range of industries. As (company name) continues to build on this success, they are laying the groundwork for a future where stronger, more durable, and more sustainable products are the new standard in manufacturing.

High-Quality CNC Machining and Sand Blasting Services for Aluminum Materials

Axis CNC Machining Sand Blasting AluminumThe process of CNC machining and sand blasting aluminum is a crucial part of the manufacturing industry. It requires precision, skill, and expertise to produce high-quality aluminum parts that are used in various industries such as aerospace, automotive, and electronics. {Company Name} is a leading provider of axis CNC machining and sand blasting services for aluminum materials. With their state-of-the-art facilities and highly skilled team, they are able to deliver top-quality products to meet the needs of their customers.Axis CNC machining is a computer-controlled process that uses multi-axis machines to remove material from aluminum blocks and create precision parts. This process is highly efficient and accurate, ensuring that the final products meet the exact specifications required by the customers. With the advanced technology used by {Company Name}, they are able to produce complex and intricate aluminum parts with tight tolerances, making them a preferred choice for many businesses in need of high-precision components.In addition to CNC machining, {Company Name} also provides sand blasting services for aluminum materials. Sand blasting is a surface treatment process that uses abrasive materials to clean, smooth, or shape a hard surface. In the case of aluminum, sand blasting can be used to remove any surface impurities, create a matte finish, or prepare the material for further coating or painting. The skilled technicians at {Company Name} have the expertise to carry out sand blasting with precision and attention to detail, ensuring that the aluminum parts are of the highest quality and finish.One of the key advantages of axis CNC machining and sand blasting aluminum at {Company Name} is their commitment to quality and continuous improvement. They have implemented strict quality control measures at every stage of the manufacturing process to ensure that the final products meet the highest standards. This includes thorough inspections, rigorous testing, and adherence to industry regulations and guidelines. As a result, customers can have full confidence in the reliability and durability of the aluminum parts produced by {Company Name}.Furthermore, {Company Name} takes pride in their dedication to customer satisfaction. They work closely with their clients to understand their specific requirements and provide tailored solutions to meet their needs. Whether it's a one-off prototype or a large-scale production run, {Company Name} has the capacity and capability to deliver on time and within budget. Their customer-centric approach has earned them a solid reputation in the industry, making them a trusted partner for businesses looking for high-quality axis CNC machining and sand blasting services for aluminum materials.The team at {Company Name} is comprised of highly skilled and experienced professionals who are passionate about their craft. They are committed to staying ahead of the curve in terms of technology, techniques, and industry trends to ensure that they continue to deliver excellence in every project they undertake. Their expertise, dedication, and attention to detail are what set them apart from their competitors, making them a go-to source for axis CNC machining and sand blasting aluminum.In conclusion, axis CNC machining and sand blasting are essential processes in the manufacturing of aluminum parts, and {Company Name} is a trusted provider of these services. With their advanced technology, skilled team, and commitment to quality, they are able to produce high-precision aluminum components for various industries. Their customer-centric approach and dedication to excellence make them a valuable partner for businesses in need of top-quality axis CNC machining and sand blasting services.

Reliable Metal Forming Services Revamp Manufacturing Processes for Enhanced Efficiency

Metal Forming Services, a renowned manufacturer in the metalworking industry, continues to revolutionize the sector with its cutting-edge technology and efficient solutions. With a dedicated team of experts and state-of-the-art facilities, the company has built a strong reputation for delivering high-quality products and exemplary customer service.Metal Forming Services is committed to meeting the growing demands of various industries, including automotive, aerospace, and construction. They offer a wide range of metal forming services, such as stamping, bending, and deep drawing. Their advanced equipment and skilled technicians allow them to tackle complex projects with precision and consistency.One of Metal Forming Services' key strengths lies in their ability to customize solutions that meet individual client specifications. They understand that every project is unique and requires a tailored approach. Through close collaboration with customers, they gather detailed requirements and provide innovative solutions that fulfill their specific needs.The company's commitment to cutting-edge technology has been instrumental in their success. They continuously invest in the latest equipment, allowing them to stay at the forefront of the industry. By embracing automation and digitalization, Metal Forming Services ensures increased efficiency, reduced lead times, and enhanced product quality.Moreover, Metal Forming Services prioritizes sustainability and adopts environmentally friendly practices throughout their operations. They understand the importance of minimizing their ecological footprint and strive to make a positive impact on the environment. From employing energy-efficient machinery to recycling waste materials, they are dedicated to promoting sustainability in the metalworking industry.As a customer-centric company, Metal Forming Services places great emphasis on delivering exceptional service. They value their relationships with clients and strive to exceed expectations at every opportunity. Their knowledgeable and friendly staff are always available to address any concerns and provide prompt assistance, making the customer experience seamless and enjoyable.To ensure consistent excellence, Metal Forming Services employs a rigorous quality control process. They adhere to stringent industry standards and implement stringent quality assurance measures. With a comprehensive inspection system in place, they guarantee that every product leaving their facility meets or exceeds the highest quality benchmarks.In addition to their commitment to quality, Metal Forming Services believes in fostering a culture of safety in the workplace. They prioritize the well-being of their employees and strictly adhere to safety protocols to minimize accidents and injuries. By providing a safe and secure working environment, they promote employee satisfaction and productivity.Metal Forming Services also prides itself on its continuous commitment to research and development. They understand the importance of staying ahead of technological advancements and industry trends. Through ongoing innovation and learning, they anticipate emerging needs and deliver solutions that cater to the evolving demands of their customers.As a market leader in the metalworking industry, Metal Forming Services continues to set the benchmark for excellence. Their unwavering dedication to customer satisfaction, technological innovation, and sustainable practices ensures that they remain at the forefront of the industry. With each project they undertake, they strive to create lasting partnerships and deliver unparalleled value to their clients.In summary, Metal Forming Services is a dynamic and forward-thinking manufacturer that offers a comprehensive range of metal forming services. With their state-of-the-art facilities, skilled workforce, and commitment to quality, the company consistently delivers exceptional solutions to a diverse clientele. Through their ongoing investment in technology and environmentally friendly practices, Metal Forming Services sets itself apart as an industry leader that is capable of meeting the ever-changing demands of modern manufacturing.

Watch the Best Sheet Metal Fabrication Videos Online

Title: Unveiling the Craft: Exploring the World of Metal FabricationIntroduction (Approximately 100 words):Metal fabrication, an essential manufacturing process that shapes raw metal sheets into intricate and functional structures, plays a vital role in various industries. From automotive parts to machinery components, the applications of metal fabrication are boundless. In this blog post, we delve into the intriguing world of metal fabrication, shedding light on the processes, techniques, and advantages that make it an indispensable aspect of modern manufacturing. Join us as we unravel the secrets behind the creation of awe-inspiring metal structures and explore the possibilities offered by a reliable Metal Fabrication Factory.1. The Art of Sheet Metal Fabrication (Approximately 200 words):Sheet metal fabrication, also known as metalworking, is a highly intricate process that involves converting raw metal sheets into products of various shapes and sizes. Through a combination of cutting, bending, and shaping techniques, skilled fabricators transform plain metal sheets into detailed structures that serve a multitude of purposes.At a Metal Fabrication Factory, advanced machinery and equipment are utilized to achieve precise results while ensuring efficiency. CNC laser cutting machines, for instance, provide accurate and consistent cuts, while hydraulic presses enable intricate bending and forming of metals. Welding and surface finishing processes are also essential to enhance the aesthetic appeal and durability of the fabricated metal structures.2. Industries Served by Metal Fabrication (Approximately 200 words):Metal fabrication caters to an extensive range of industries and sectors. From construction and architecture to transportation and manufacturing, the applications are limitless. For example, in the construction industry, architectural metalwork such as staircases, handrails, and structural components are fabricated to ensure functionality, strength, and aesthetic appeal.The automotive industry heavily relies on metal fabrication to manufacture critical components like chassis, exhaust systems, and suspension parts. Metal fabrication is also crucial in the production of electrical enclosures, HVAC systems, and machinery components that are utilized in various manufacturing plants.3. The Advantages of Metal Fabrication (Approximately 200 words):Metal fabrication offers numerous advantages that make it the go-to manufacturing process for countless industries. First and foremost is the versatility it provides. Metal can be shaped into intricate designs and structures, making it suitable for both functional and aesthetic purposes. Additionally, metals are inherently strong and durable, ensuring the longevity of fabricated products.Moreover, metal fabrication allows for quick prototyping and customization. By utilizing computer-aided design (CAD) software, fabricators can create detailed digital designs, optimize them for precision, and then produce multiple replicas with ease.Furthermore, metal fabrication is a cost-effective solution as it eliminates the need for intricate assembly processes that add to the overall expenses. By integrating multiple manufacturing steps into one streamlined process, metal fabrication increases efficiency and reduces production time.4. Choosing a Metal Fabrication Factory (Approximately 200 words):When selecting a metal fabrication factory, various factors must be considered to ensure high-quality results. Look for a facility equipped with state-of-the-art machinery and cutting-edge technology that can meet your specific project requirements. Cross-check the factory's capabilities, such as laser cutting, bending, welding, and finishing, to ensure they align with your needs.Certifications and industry credentials are also important indicators of the fabricator's reliability and expertise. Prioritize a factory that adheres to international standards to guarantee exceptional quality and compliance with regulatory norms.Additionally, consider the factory's experience in your specific industry. A well-established fabricator with a portfolio of successful projects in your desired sector is more likely to understand the unique challenges and deliver tailored solutions.Conclusion (Approximately 100 words):Metal fabrication remains an essential pillar of modern manufacturing, enabling the creation of intricate and durable structures in diverse industries. The artistry and skill behind metal fabrication, combined with advanced machinery and technology, make it a captivating subject to explore. By partnering with a trustworthy Metal Fabrication Factory, businesses can unlock the potential of this versatile process, leveraging its advantages to bring their innovative ideas to life. So, whether you require custom architectural metalwork or need precise automotive components, metal fabrication is the key to turning your visions into reality.