Top Quality Auto Parts Made in China: A Complete Guide

By:Admin

China Auto Parts specializes in producing a wide range of auto parts, including brake pads, oil filters, air filters, spark plugs, and much more. The company is dedicated to using the latest technology and the highest quality materials in its manufacturing processes, ensuring that all of its products meet or exceed industry standards.

One of the key factors that sets China Auto Parts apart from its competitors is its dedication to research and development. The company has a team of highly skilled engineers and product designers who are constantly working to develop new and innovative products that will meet the ever-changing needs of the automotive industry. This commitment to innovation has allowed China Auto Parts to stay ahead of the curve and continue to be a leader in the market.

In addition to its extensive product line, China Auto Parts also prides itself on its commitment to quality control. The company has implemented strict manufacturing and testing processes to ensure that all of its products are of the highest quality. This dedication to quality has earned China Auto Parts a loyal customer base, as automotive professionals and consumers alike trust the company to provide reliable and durable auto parts.

Furthermore, China Auto Parts also places a strong emphasis on sustainability and environmental responsibility. The company is committed to reducing its carbon footprint and minimizing its impact on the environment. It has implemented various eco-friendly practices in its manufacturing processes, such as using recyclable materials and reducing waste. This commitment to sustainability has not only earned China Auto Parts accolades within the industry, but has also resonated with environmentally-conscious consumers.

One of the most notable products that China Auto Parts has recently introduced to the market is its advanced brake pad technology. The company's new brake pads are designed to deliver superior performance and durability, offering exceptional stopping power and extended lifespan. These brake pads have been rigorously tested and have received high praise from industry professionals and consumers alike.

In addition to its focus on quality and innovation, China Auto Parts is also dedicated to providing outstanding customer service. The company has established a strong distribution network, ensuring that its products are readily available to customers around the world. It also offers comprehensive technical support and assistance to help customers with any questions or concerns they may have.

Looking ahead, China Auto Parts has ambitious plans for the future. The company is continuously expanding its product line and exploring new markets to further solidify its position as a leading auto parts manufacturer. With its unwavering commitment to excellence, innovation, and sustainability, China Auto Parts is well-positioned to continue making significant contributions to the automotive industry.

Overall, China Auto Parts is a company that is truly making a difference in the auto parts industry. With its dedication to quality, innovation, and customer satisfaction, it has earned a well-deserved reputation as a trusted and respected supplier of auto parts. As the company continues to grow and evolve, it is clear that China Auto Parts will remain a driving force in the industry for years to come.

Company News & Blog

New technique for eco-friendly microstructure etching on complex-shaped components

Technique, Microstructures, Environmentally-Friendly, Free-Form Surfaces, Traditional Etching Methods, Efficiency, SustainabilityThe development of a new laser cutting technique by German researchers promises to revolutionize the way we etch microstructures into complex-shaped surfaces. This new method is expected to be more environmentally friendly and efficient than traditional etching methods, which use chemicals to remove surface material.The technique involves using a laser beam to burn micrometre-fine patterns into free-form surfaces, creating fine microstructures that were previously impossible to achieve with traditional etching methods. In addition to being more precise, this laser cutting technique is believed to be cheaper and more sustainable than its predecessors, making it a more accessible solution for a wider range of applications.One area where this technique is expected to have a significant impact is in the development and production of prototypes. With the Prototype Laser Cutting Technique, it will be easier and more efficient to create fine microstructures on complex-shaped components, which are essential for prototyping. This is an important step in the development of products, as prototypes allow companies to test and refine their products before mass production.The development of this laser cutting technique is a major step towards improving efficiency and sustainability in various industries. It has the potential to revolutionize the manufacturing process by making it more accessible and cost-effective. In addition to being used in prototyping, this technique will be useful for a variety of other applications, including the production of electronics, medical devices, and other precision components.In conclusion, this new Prototype Laser Cutting Technique is a game-changer in the world of microstructure etching. It offers a more environmentally-friendly, efficient, and cost-effective solution than traditional etching methods. With potential applications in a wide range of industries, this laser cutting technique has the potential to revolutionize the way we create precision components and prototypes.

Sheet Metal Fabrication Services in the USA at Competitive Prices

Sheet Metal Fabrication Shop: Providing Quality Sheets for Your Manufacturing NeedsIn today's manufacturing industry, sheet metal fabrication is an integral part of producing finished products. From appliances, automotive parts, to custom enclosures, sheet metal is the backbone of every product that requires strength, durability, and precision.To meet the demands of this competitive market, industries turn to sheet metal fabrication shops to provide high-quality sheets and services. These shops specialize in the production, designing, and finishing of sheet metal products that meet the unique requirements of every client.Sheet metal fabrication shops play a crucial role in the manufacturing industry. Here's why:Fabrication CapabilitiesSheet metal fabrication shops have advanced technology and a team of skilled professionals that can handle even the most complex sheet metal projects. They use computer-aided design (CAD) and computer-aided manufacturing (CAM) to create precise and accurate designs that can be easily edited and modified. With their cutting-edge machines and techniques, they can create any shape, size, or design you require.High-Volume Precision ServicesSheet metal fabrication shops pride themselves on providing high-volume precision services. They ensure that every piece of sheet metal they produce meets the exact specifications set by the client. They use a variety of tools and techniques, such as CNC machining, stamping, laser cutting, and welding, to produce sheet metal products that are durable, safe, and meet all industry standards.Fast Delivery OptionsThe fast-paced manufacturing industry demands quick turnaround times. Sheet metal fabrication shops understand the importance of delivering finished products on time, every time. They prioritize meeting deadlines and have streamlined processes to ensure that each project is delivered promptly without compromising quality.Competitive PricingSheet metal fabrication shops offer competitive pricing for their products and services. With their advanced technology and streamlined processes, they can provide cost-effective solutions to meet every client's needs while maintaining the highest quality standards.In conclusion, sheet metal fabrication shops play an essential role in the manufacturing industry. They take pride in providing high-quality sheet metal products that meet the specific needs of their clients. They have the experience, expertise, and technology to handle any sheet metal project, big or small, and deliver it on time and within budget with competitive pricing. If you require sheet metal products, turn to a reputable sheet metal fabrication shop to ensure that your products are safe, durable, and of the highest quality.

Trendy Steel and Fabrication Options for Your Projects

Steel And Fabrication Company Joins Forces with Leading ManufacturerThe [Company Name] is proud to announce its recent collaboration with a leading manufacturer in the industry. This partnership is set to establish a unique and innovative approach to steel fabrication that will further elevate the company's position as a leader in the field.With decades of experience in steel fabrication, [Company Name] has been revered for its high-quality products and exceptional customer service. The company has built a strong reputation for its ability to handle a wide range of projects, from small-scale custom fabrications to large industrial constructions. By providing clients with personalized solutions and superior craftsmanship, [Company Name] has consistently proven itself to be a top choice for steel fabrication needs.The recent partnership with the leading manufacturer comes as an exciting development for [Company Name]. With a shared commitment to excellence and cutting-edge innovation, this collaboration is expected to yield groundbreaking results in the industry. By combining resources and expertise, the two companies aim to deliver even more advanced and efficient solutions to their clients.One of the key benefits of this collaboration is the expanded range of capabilities that will be available to clients. The partnership will enable [Company Name] to leverage the manufacturer's state-of-the-art technologies and advanced materials, allowing for the creation of even more complex and intricate designs. This will ultimately translate to greater flexibility and creativity in meeting the diverse needs of customers.Furthermore, the collaboration will also result in enhanced efficiency and cost-effectiveness. By streamlining processes and optimizing resources, [Company Name] will be able to offer competitive pricing without compromising on quality. Clients can expect to receive the same level of excellence they have come to expect from [Company Name], but with added value and affordability.In addition to technological advancements, the partnership will also foster a culture of continuous improvement within [Company Name]. Through knowledge sharing and best practices exchange, the company will further bolster its internal capabilities and elevate its standards of operation. This will ultimately benefit clients, as they will be met with heightened levels of professionalism and proficiency.Another significant aspect of this collaboration is the emphasis on sustainability and environmental responsibility. Both [Company Name] and the leading manufacturer are committed to minimizing their ecological footprint and promoting sustainable practices. By working together, they will explore new ways to integrate eco-friendly materials and processes into their operations, thereby contributing to a greener and more sustainable industry.The leadership team at [Company Name] is enthusiastic about the prospects of this collaboration and the positive impact it will have on their clients. By aligning with a reputable and forward-thinking partner, [Company Name] is reinforcing its commitment to providing unparalleled service and staying at the forefront of the industry.As for the leading manufacturer, they see this partnership as an opportunity to further expand their reach and influence within the market. By teaming up with [Company Name], they will have a trusted and capable partner to help them realize their vision of delivering top-notch solutions to a wider audience.In conclusion, the collaboration between [Company Name] and the leading manufacturer represents a significant milestone for the steel fabrication industry. This partnership is set to drive progress and innovation, ultimately benefiting clients and setting a new standard for excellence in the field. As the two companies embark on this new chapter together, they look forward to the exciting possibilities that lie ahead.

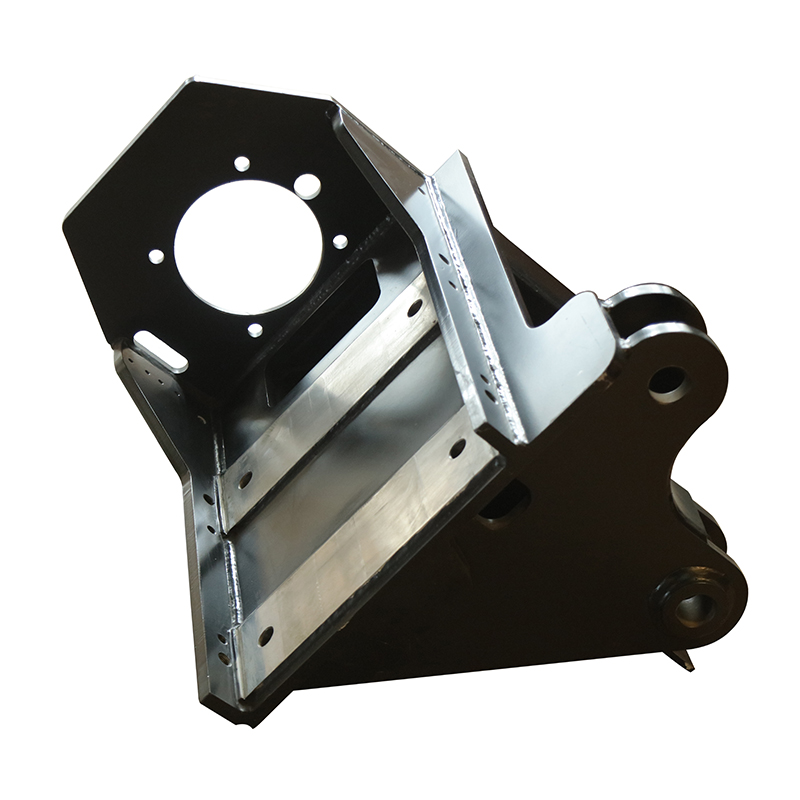

Custom Metal Fabrication Suppliers for Electrical and Control Boxes in China

Hangzhou Qianqi Industry Co., Ltd.: Leading the Way in Custom Metal FabricationHangzhou Qianqi Industry Co., Ltd. is a leading manufacturer and supplier of custom metal fabrication. The company has been established for over a decade, and has built a reputation for manufacturing quality metal products that meet the highest standards. With an experienced team and state-of-the-art equipment, Hangzhou Qianqi Industry Co., Ltd. is able to provide a wide range of custom metal fabrication services to meet the unique needs of its clients.Custom metal fabrication involves the production of metal products such as machine parts, electrical cabinets, junction boxes, and control boxes. These products can be made from various types of metal including steel, aluminum, brass, and copper, among others. Hangzhou Qianqi Industry Co., Ltd. has a team of experts who have expertise in working with these materials, and are able to craft unique and functional products that meet the needs of clients across a range of industries.One of the key strengths of Hangzhou Qianqi Industry Co., Ltd. is its ability to work with clients from start to finish in the product development process. Its team of skilled engineers and designers are able to develop custom solutions to meet the specific needs of each client. With a focus on quality, efficiency, and client satisfaction, the company provides design assistance, prototyping, and full-scale production services to ensure that each product meets the requirements of its intended application.The company's production capabilities are broad, and include cutting, drilling, welding, bending, and finishing. With its state-of-the-art equipment and skilled production team, Hangzhou Qianqi Industry Co., Ltd. is able to produce products that are accurate, functional, and durable. The company has years of experience in production management, and is able to ensure that projects are delivered on time and within budget.One of the key highlights of Hangzhou Qianqi Industry Co., Ltd. is its commitment to quality. The company has implemented a quality management system that is certified to ISO 9001:2015. This means that all of its products are held to the highest standards of quality and durability. The company also has a rigorous quality control process to ensure that each product meets the requirements of its intended application.In addition to quality and excellence, Hangzhou Qianqi Industry Co., Ltd. places a strong emphasis on sustainability. The company is committed to reducing its environmental impact and has taken measures to ensure that it operates in an environmentally responsible manner. This includes the use of eco-friendly materials and the implementation of practices that reduce waste and minimize energy consumption.Hangzhou Qianqi Industry Co., Ltd. is a company that takes pride in its ability to provide custom metal fabrication services that meet the highest standards of quality and customer satisfaction. With an experienced team, state-of-the-art equipment, and a commitment to excellence, the company is poised to continue leading the way in the metal fabrication industry.In closing, Hangzhou Qianqi Industry Co., Ltd. is a company that has built a reputation for providing exceptional custom metal fabrication services. With a focus on quality, efficiency, and customer satisfaction, the company has distinguished itself as a leader in the industry. Its commitment to sustainability and its use of state-of-the-art equipment ensure that clients can trust Hangzhou Qianqi Industry Co., Ltd. to provide reliable, high-quality products that meet their unique needs.

US Manufacturer Launches High-Quality Precision Metal Fabrication Services" can be rewritten as "New High-Quality Precision Metal Fabrication Services Now Available in the US.

Precision Fabrications, a leading manufacturing company, is making headlines with its cutting-edge technologies and innovative solutions in the industry. With a strong commitment to quality and customer satisfaction, Precision Fabrications continues to excel in delivering exceptional products and services to its clients worldwide.Established several decades ago, Precision Fabrications has evolved into a global powerhouse in the manufacturing sector. Specializing in the production of precision components and fabricated metal products, the company has garnered a reputation for its expertise, reliability, and attention to detail. With state-of-the-art facilities and a highly skilled workforce, Precision Fabrications is well-equipped to meet the ever-growing demands of its diverse clientele.One of the key strengths of Precision Fabrications lies in its extensive range of capabilities. The company possesses a wide variety of machining and fabrication equipment, allowing it to produce intricate components with utmost precision. From CNC machining and turning to welding and assembly, Precision Fabrications offers comprehensive solutions tailored to meet the unique needs of each client. By combining advanced manufacturing techniques with rigorous quality control measures, the company ensures that every product leaving its facility is of the highest standard.Precision Fabrications serves clients across diverse sectors, including aerospace, automotive, medical, and energy. By catering to such diverse industries, the company has gained invaluable experience in navigating complex manufacturing challenges and delivering solutions that exceed expectations. Its commitment to continuous improvement and investment in research and development have enabled Precision Fabrications to stay ahead of the curve, offering cutting-edge technologies and innovative solutions that keep its clients at the forefront of their respective industries.In addition to its technical expertise, Precision Fabrications places great emphasis on building strong and lasting relationships with its clients. The company recognizes that open communication and collaboration are crucial to ensuring successful partnerships. By actively engaging with clients from project inception to completion, Precision Fabrications is able to fully understand their needs and develop customized solutions that address their specific requirements. This client-focused approach has earned the company a solid reputation for its reliability and ability to deliver on time and within budget.Precision Fabrications also prides itself on its commitment to sustainability and environmental responsibility. The company actively seeks ways to minimize its ecological footprint through efficient use of resources, waste reduction, and recycling initiatives. By implementing eco-friendly practices throughout its operations, Precision Fabrications not only contributes to a greener planet but also demonstrates its commitment to corporate social responsibility.Looking towards the future, Precision Fabrications remains driven by a strong vision to be at the forefront of technological advancements in the manufacturing industry. The company continues to invest in research and development, exploring emerging technologies such as additive manufacturing and automation to further enhance its capabilities. By embracing innovation and staying ahead of industry trends, Precision Fabrications aims to provide its clients with cutting-edge solutions that drive their success in an ever-evolving global market.In conclusion, Precision Fabrications is a leading manufacturing company that has established itself as a trusted partner for clients worldwide. With its commitment to quality, technical expertise, and customer satisfaction, the company continues to deliver exceptional products and services across diverse industries. As it remains dedicated to innovation and sustainability, Precision Fabrications is poised to shape the future of the manufacturing sector, setting new industry standards and raising the bar for excellence.

Revolutionary Laser Cutting Technology Introduces Groundbreaking Solutions for Engineering Industry

Laser Cutting: The Optimal Solution for Aluminium Cutting Aluminium is a widely used material, utilized in various industries such as automotive, aerospace, construction, and electronics. Its unique properties such as lightweight, durable, corrosion-resistant, and versatile make it a sought-after material. However, cutting through Aluminium can prove to be a challenging task due to its high thermal conductivity and low melting point. To overcome this challenge, Aluminium Laser Cutting Service is the optimal solution.Laser cutting is a precision technique that uses a high-powered laser beam to cut through different materials, including Aluminium. The laser beam melts, burns, or vaporizes the Aluminium material, producing a clean and precise cut. This method provides various advantages compared to traditional cutting methods such as sawing or milling. Some of the benefits include:1. Precision: Laser cutting provides a precise and accurate cut that is difficult to achieve through other methods. This is because the laser beam follows a pre-programmed path, ensuring that the cut is exact and consistent throughout the material.2. Efficiency: Laser cutting is a quick and efficient method, with the ability to cut multiple shapes and sizes within seconds. This is ideal for large-scale production and can save a significant amount of time, cost, and labor.3. Clean Cut: The laser beam produces minimal heat and leaves no residue or burrs after cutting. This results in a clean and smooth cut that requires minimal post-processing compared to other cutting methods.4. Versatility: Laser cutting is a versatile method that can cut through a wide range of materials, including Aluminium, stainless steel, copper, and acrylics. This means that businesses can cut different materials using the same machine, eliminating the need for multiple setups and equipment.Aluminium Laser Cutting provides an array of applications in various industries. In the automotive industry, Aluminium laser cutting is used to produce lightweight car parts, which reduces fuel consumption and emissions. In the aerospace industry, Aluminium Laser Cutting is used to create intricate parts for aircraft such as wings, engine parts, and landing gear. In construction, Aluminium Laser Cutting is used to produce parts for doors, windows, and frames.In conclusion, Laser Cutting is the optimal solution for cutting Aluminium materials due to its precision, efficiency, and versatility. It provides a clean and consistent cut that is difficult to achieve through traditional cutting methods. As a result, Aluminium Laser Cutting can save time, cost, and labor while maintaining high-quality standards. Contact your local Aluminium Laser Cutting service provider today for all your Aluminium cutting needs.

Discover the Best Techniques for Welding Stainless Steel to Stainless Steel

Welding Stainless To Stainless: A Seamless Connection for Durable Strength[Placeholder for brand name removal] Industries, a leading manufacturer of welding equipment and solutions, continues to push the boundaries of innovation in the welding industry. With a strong commitment to excellence and customer satisfaction, [Placeholder for brand name removal] has introduced its latest welding technology, specifically designed for welding stainless steel to stainless steel. This cutting-edge solution promises a seamless connection, providing unparalleled strength and durability.As stainless steel has become a popular choice of material in various industries, the need for efficient and reliable welding techniques has grown significantly. Welding stainless steel to stainless steel requires precision and expertise to ensure a strong bond that can withstand the test of time. This is where [Placeholder for brand name removal] Industries steps in, offering a revolutionary solution that simplifies the welding process while delivering impeccable results.The key to [Placeholder for brand name removal]'s success lies in its advanced welding technology, specifically designed to overcome the challenges associated with welding stainless steel. This innovative technology not only guarantees a strong and seamless connection but also ensures that the final weld is resistant to corrosion, a common concern when working with stainless steel.One of the standout features of this welding solution is its versatility. [Placeholder for brand name removal] Industries has developed a range of welding equipment suitable for various applications, catering to the diverse needs of industries such as construction, automotive, aerospace, and more. Whether it's joining thin sheets of stainless steel or fabricating complex structures, [Placeholder for brand name removal] provides tailored solutions to meet every requirement.The welding process itself is highly efficient, allowing for faster completion times and increased productivity. Thanks to [Placeholder for brand name removal]'s state-of-the-art technology, welders can now achieve high-quality results in a fraction of the time typically required for stainless steel welding. This not only saves valuable time but also reduces overall costs, making it an attractive solution for businesses seeking to streamline their operations.Furthermore, [Placeholder for brand name removal] Industries ensures that its welding equipment is user-friendly, even for welders with limited experience. The machines are equipped with intuitive interfaces and advanced controls, making the welding process more accessible and less prone to errors. This user-centric approach reflects [Placeholder for brand name removal]'s commitment to empowering welders and enhancing their capabilities.But it doesn't end there. [Placeholder for brand name removal]'s dedication to customer satisfaction extends beyond its innovative products. The company provides comprehensive technical support and training to its customers, ensuring seamless integration and maximum efficiency. With a team of knowledgeable experts at their disposal, customers can rely on [Placeholder for brand name removal] for guidance and assistance at every step of their welding journey.In conclusion, [Placeholder for brand name removal] Industries has revolutionized the welding industry with its groundbreaking technology for welding stainless steel to stainless steel. By combining precision, durability, and user-friendliness, [Placeholder for brand name removal] has introduced a solution that simplifies the welding process while delivering exceptional results. As businesses across different industries continue to rely on stainless steel for their projects, [Placeholder for brand name removal] remains at the forefront of innovation, providing an indispensable tool to ensure strong and durable connections that stand the test of time.

Sheet Metal Fabrication: The Process and Uses of Copper Sheets

Copper Sheet Metal Fabrication Company Helps Businesses Meet Demand for Custom Metal PartsAs the demand for custom metal parts continues to grow across numerous industries, businesses need reliable partners to help them meet their needs. That’s where Copper Sheet Metal Fabrication (CSMF), one of the leading metal fabrication companies in the country, comes in.Based in the heart of the industrial Midwest, CSMF has been serving the needs of businesses of all sizes for over two decades. During that time, they’ve developed a reputation as a company that can deliver high-quality metal parts with quick turnaround times and competitive pricing.One of the keys to CSMF’s success is their ability to work with a wide range of metals. In addition to copper, they work with materials like aluminum, brass, stainless steel, and cold-rolled steel, among others. This versatility allows them to serve a variety of industries, from automotive to construction to oil and gas.But it’s their expertise in copper fabrication that really sets them apart. Copper is a unique metal that requires specialized knowledge and techniques to work with. And as demand for copper parts continues to soar due to its high conductivity, anti-microbial properties, and other unique attributes, the need for skilled copper fabricators has never been greater.That’s where CSMF’s team of experienced copper fabricators come in. They have years of experience working with copper in all its forms, from sheets and coils to rods and wire. They use the latest techniques and equipment to ensure precision and consistency in every part they produce.But CSMF isn’t just known for their technical expertise. They also pride themselves on their exceptional customer service. From the moment a customer places an order to the moment it’s delivered, CSMF’s team is there to provide support and guidance every step of the way. They work closely with customers to understand their unique needs and ensure that the final product meets their exact specifications.This commitment to quality and service has earned CSMF a loyal base of customers from across the country. Customers praise them for their reliability, attention to detail, and ability to deliver high-quality parts on time and on budget. And as the demand for custom metal parts continues to grow, CSMF is poised to remain a leading provider of copper fabrication services for years to come.But CSMF isn’t resting on its laurels. They continue to invest in new equipment and technology to improve their processes and stay ahead of the competition. They’re always looking for new ways to streamline their operations and deliver even better results for their customers.For businesses looking for a partner in custom metal fabrication, CSMF is a name they can trust. With their expertise in copper fabrication, their commitment to quality, and their exceptional customer service, they’re well positioned to help businesses of all sizes meet their metal fabrication needs.

Discover a Wide Range of Bending Products and Services on Ferret.com.au

CNC Bending Service: The Future of Metal FabricationMetal fabrication has come a long way since the days of manual hand-operated machines, where the process of metal bending was labor-intensive and required skilled craftsmen. Today, computer numerical control (CNC) technology has revolutionized the manufacturing industry, making it faster, more efficient, and highly accurate.What is CNC Bending?CNC Bending is a process of metal forming that utilizes computer-controlled machines to create precise and complex bends in sheet metal and other materials. CNC machines can perform multiple bends in a single cycle, and they are capable of producing large quantities of parts with minimal operator intervention.The Advantages of CNC BendingCNC metal bending offers several advantages over traditional metal forming methods, including:1. High precision: CNC machines are highly accurate and can produce parts with precise tolerances.2. Rapid production: CNC bending machines can produce parts at a faster rate than manual bending machines, making the process more efficient and cost-effective.3. Versatility: CNC machines can perform multiple bending operations in a single cycle, allowing for the creation of complex shapes and intricate designs.4. Consistency: CNC machines can produce identical parts with the same level of precision every time, ensuring consistency in the final product.5. Reduced waste: CNC machines are programmed to optimize material usage, reducing waste and saving costs.Applications of CNC BendingCNC bending is widely used in various industries, including aerospace, automotive, construction, and electronics. Some of the common applications of CNC bending include:1. Fabrication of metal enclosures, chassis, and panels.2. Production of brackets, frames, and supports.3. Creation of bends in pipes and tubes.4. Manufacturing of complex shapes for medical devices.Choosing the Right CNC Bending Service ProviderWhen it comes to CNC bending services, it’s essential to choose a reliable and experienced service provider that can deliver quality results. Here are some factors to consider when selecting a CNC bending service provider:1. Technology: Choose a provider that uses the latest CNC bending technology and equipment to ensure high precision and efficiency.2. Experience: Look for a provider with years of experience in CNC bending and a proven track record of delivering quality results.3. Capacity: Consider the provider’s capacity to handle your specific project requirements, including materials, specifications, and volume.4. Quality control: Ensure that the provider has a robust quality control process in place to ensure the final product meets your specifications.5. Cost-effectiveness: Compare quotes from multiple providers and choose the one that offers the best value for your money.ConclusionCNC bending is the future of metal fabrication, and its advantages over traditional metal forming methods make it an ideal choice for various industries. By choosing the right CNC bending service provider, you can ensure that your project is produced with high precision, efficiency, and quality. Contact us today to learn more about our CNC bending services!

How Laser Cutting is Transforming Sheet Metal Manufacturing

Sheet metal laser cutting technology has revolutionized the manufacturing industry, providing companies with precise and efficient cutting capabilities for a wide range of materials. One company that has been at the forefront of this technology is {Company Name}, a leading provider of sheet metal fabrication and laser cutting services.With over 20 years of experience in the industry, {Company Name} has established itself as a reliable and innovative partner for businesses seeking high-quality sheet metal fabrication solutions. The company's state-of-the-art facility is equipped with advanced machinery, including the latest sheet metal laser cutting technology, allowing them to meet the diverse needs of their clients.The sheet metal laser cutting process involves the use of a high-powered laser to precisely cut through various types of metal sheets with speed and accuracy. This technology has significantly improved the efficiency and quality of metal fabrication, allowing for intricate designs and complex shapes to be easily achieved.{Company Name} has invested in the most advanced sheet metal laser cutting machines, ensuring that they can handle a wide range of materials, including stainless steel, aluminum, and copper, with thicknesses ranging from thin gauge to heavy plate. The company's team of skilled engineers and technicians are trained in the latest laser cutting techniques, enabling them to deliver precise and reliable results for their clients.In addition to its cutting-edge technology, {Company Name} is committed to providing exceptional customer service and support. The company works closely with each client to understand their specific requirements and objectives, offering customized solutions to meet their needs. Whether it's a one-off prototype or a large-scale production run, {Company Name} has the expertise and capabilities to deliver high-quality sheet metal products on time and within budget.{Company Name} serves a wide range of industries, including automotive, aerospace, electronics, and telecommunications, among others. The company's ability to handle complex projects and deliver superior results has earned them a solid reputation within the industry, making them a trusted partner for businesses looking for reliable sheet metal fabrication services.As the manufacturing industry continues to evolve, {Company Name} remains committed to staying ahead of the curve by investing in the latest sheet metal laser cutting technology and expanding its capabilities. This dedication to innovation and excellence has allowed the company to grow and adapt to the ever-changing needs of its clients, solidifying its position as a leader in the sheet metal fabrication industry.In conclusion, sheet metal laser cutting technology has become an essential tool for modern manufacturing, and {Company Name} has established itself as a premier provider of laser cutting services. With its advanced machinery, skilled team, and commitment to customer satisfaction, {Company Name} is well-equipped to meet the diverse needs of businesses across various industries. As the demand for high-quality sheet metal fabrication continues to grow, {Company Name} is poised to remain at the forefront of the industry, delivering innovative solutions and superior results for its clients.