Welding Cast Steel to Mild Steel: How to Seamlessly Join Different Metals

By:Admin

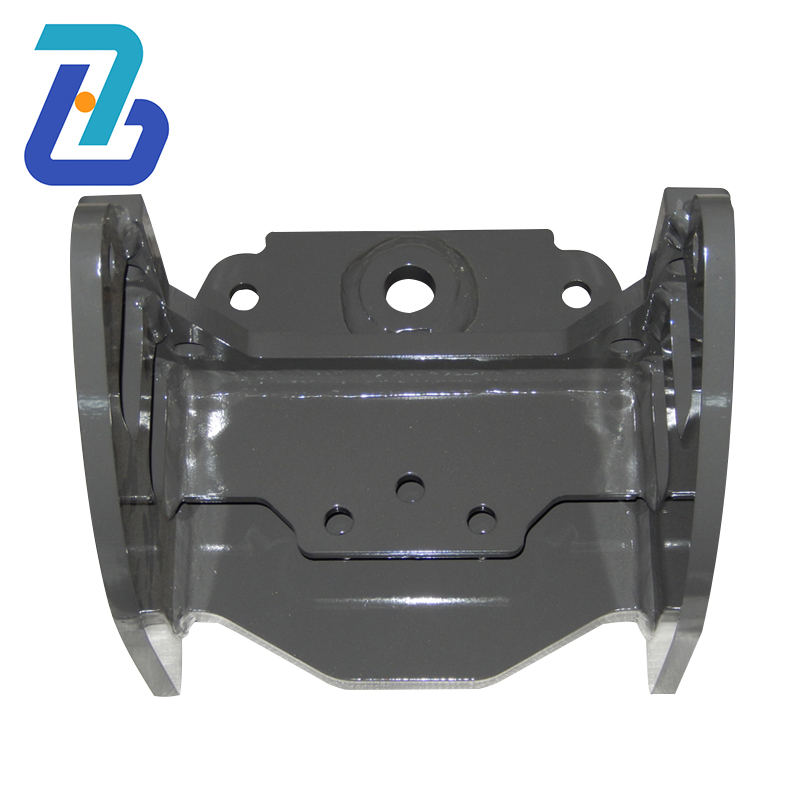

Welding is a crucial process in the manufacturing industry, and it requires precision and expertise to ensure the quality and durability of the final product. One of the most common welding processes is joining cast steel to mild steel, a technique that requires skill and the right equipment to achieve a strong and reliable bond.

{} is a leading company in the welding industry, specializing in providing high-quality welding equipment and solutions for various applications. With a strong focus on innovation and customer satisfaction, {} has been at the forefront of developing advanced welding technologies that meet the needs of modern industries.

When it comes to welding cast steel to mild steel, {} has proven to be a trusted partner for many manufacturing companies. With a wide range of welding equipment and consumables, {} offers the right tools and expertise to achieve a successful weld between cast steel and mild steel.

The process of welding cast steel to mild steel requires careful preparation and execution to ensure a strong and durable bond. {} provides a comprehensive range of welding consumables, including electrodes, wires, and fluxes, specially designed for welding cast steel to mild steel. These consumables are manufactured to the highest standards, ensuring the integrity of the weld and the quality of the final product.

In addition to providing high-quality consumables, {} also offers a range of welding equipment designed for joining cast steel to mild steel. From advanced welding machines to cutting-edge welding torches and accessories, {} provides the necessary tools for achieving a precise and reliable weld.

One of the key challenges in welding cast steel to mild steel is the difference in the composition and properties of the two materials. Cast steel is known for its high strength and resistance to wear, while mild steel is more ductile and easier to weld. {} understands the unique characteristics of both materials and offers specialized welding solutions to overcome the challenges of joining them together.

With a team of experienced technicians and engineers, {} also provides technical support and expertise to help customers optimize their welding processes. From selecting the right consumables to fine-tuning welding parameters, {} works closely with its customers to ensure a successful weld between cast steel and mild steel.

In addition to its expertise in welding technology, {} is also committed to innovation and continuous improvement. The company invests in research and development to advance the capabilities of its welding equipment and consumables, ensuring that customers have access to the latest technologies for welding cast steel to mild steel.

Furthermore, {} is dedicated to providing comprehensive training and support to its customers, empowering them with the knowledge and skills to achieve high-quality welds. Through its training programs and technical workshops, {} equips welding professionals with the expertise they need to master the process of joining cast steel to mild steel.

As a trusted partner in the welding industry, {} has built a reputation for delivering reliable solutions and exceptional customer service. The company's commitment to quality and innovation has established {} as a preferred supplier for welding equipment and consumables, particularly for challenging applications such as welding cast steel to mild steel.

In conclusion, welding cast steel to mild steel is a critical process that requires precision, expertise, and the right equipment. With its comprehensive range of welding solutions and technical support, {} has emerged as a leading provider of high-quality welding technology for joining cast steel to mild steel. As manufacturing industries continue to evolve, {} remains dedicated to supporting its customers with advanced welding solutions that meet their specific needs and challenges.

Company News & Blog

Custom Metal Fabrication Services for All Your Needs

All Metal Fabrication Services, a leading provider of metal fabrication solutions, has recently announced the expansion of their services to meet the growing demands of the metal fabrication industry. With over 20 years of experience in the field, the company has established itself as a reliable and trusted partner for businesses looking for custom metal fabrication solutions.Specializing in a wide range of fabrication services, including laser cutting, welding, and metal forming, the company has the expertise and equipment to handle projects of all sizes and complexities. Their state-of-the-art facility is equipped with the latest technology and machinery, allowing them to deliver high-quality products with fast turnaround times.The expansion of their services comes as a response to the increasing demand for custom metal fabrication solutions in various industries, including construction, automotive, and aerospace. With their extensive experience and expertise, All Metal Fabrication Services is well-positioned to meet the needs of their clients and provide solutions that meet the highest standards of quality and precision.“Our goal is to provide our clients with the best metal fabrication solutions that meet their specific needs and requirements,” said a spokesperson for the company. “We are constantly expanding our capabilities and investing in the latest technology to ensure that we can deliver the highest quality products and services to our clients.”In addition to their fabrication services, All Metal Fabrication Services also offers design and engineering support to help their clients bring their ideas to life. With a team of experienced engineers and designers, the company can assist with product development, prototyping, and custom fabrication projects, providing a complete solution from concept to production.The company’s commitment to quality and customer satisfaction has earned them a reputation as a reliable and trusted partner in the metal fabrication industry. By expanding their services, they aim to further solidify their position as a leading provider of custom metal fabrication solutions, offering a one-stop shop for all metal fabrication needs.With their expanded services, All Metal Fabrication Services is well-equipped to take on a wide range of projects, from small-scale prototypes to large-scale production runs. Their comprehensive capabilities and commitment to excellence make them a go-to choice for businesses looking for reliable and high-quality metal fabrication solutions.For businesses in need of custom metal fabrication solutions, All Metal Fabrication Services provides a one-stop shop for all their needs. With their extensive experience, state-of-the-art facility, and commitment to quality, the company is well-positioned to meet the growing demands of the metal fabrication industry and provide comprehensive solutions for businesses across various sectors.As they continue to expand and enhance their capabilities, All Metal Fabrication Services aims to remain at the forefront of the metal fabrication industry, providing innovative and reliable solutions that meet the evolving needs of their clients. Their dedication to quality and customer satisfaction sets them apart as a leading provider of custom metal fabrication services, capable of delivering the highest standards of excellence in every project they undertake.For businesses looking for a trusted partner in the metal fabrication industry, All Metal Fabrication Services offers the expertise, experience, and capabilities needed to bring their projects to life. With their expanded services and commitment to excellence, the company is well-equipped to meet the growing demands of the industry and provide comprehensive solutions for businesses of all sizes.

High-Quality Steel and Fabrication Services for Commercial and Residential Projects

Steel And Fabrication Company Celebrates 20 Years of Excellence in Fabrication and Manufacturing[Company Name] is a leading steel and fabrication company that has been providing top-notch services in the fabrication and manufacturing industry for the past 20 years. The company has a proven track record of delivering high-quality products and exceptional customer service, making them a trusted and reliable partner for businesses across various industries.Founded in 2001, [Company Name] has steadily grown to become a powerhouse in the fabrication and manufacturing sector. With a state-of-the-art facility and a team of highly skilled and experienced professionals, the company has the capabilities to handle projects of all sizes and complexities. From custom steel fabrication to heavy equipment manufacturing, [Company Name] offers a wide range of services to cater to the diverse needs of its clients.Over the years, [Company Name] has built a solid reputation for consistently delivering superior products and services. The company is committed to upholding the highest standards of quality and precision in its work, ensuring that every project is completed to perfection. From concept to completion, [Company Name] works closely with its clients to understand their unique requirements and provide tailor-made solutions that exceed expectations.One of the key factors that sets [Company Name] apart from its competitors is its dedication to innovation and continuous improvement. The company invests heavily in cutting-edge technology and machinery to enhance its capabilities and stay ahead of industry trends. This commitment to innovation has enabled [Company Name] to tackle complex projects with efficiency and effectiveness, earning the trust and loyalty of its clients.In addition to its technical expertise, [Company Name] also prides itself on its unwavering commitment to safety and environmental sustainability. The company adheres to strict safety protocols and best practices to ensure the well-being of its employees and the preservation of the environment. By prioritizing safety and sustainability, [Company Name] demonstrates its responsibility as a corporate citizen and a steward of the community.As [Company Name] celebrates its 20th anniversary, the company looks back on its journey with a sense of pride and accomplishment. Over the years, [Company Name] has successfully completed a wide array of projects across different industries, from construction and infrastructure to oil and gas. The company's versatility and expertise have earned it a stellar reputation in the fabrication and manufacturing sector, positioning it as a preferred partner for leading businesses.Looking ahead, [Company Name] is poised for continued success and growth in the years to come. The company remains committed to delivering best-in-class products and services, upholding its core values of quality, integrity, and reliability. With a focus on innovation and customer satisfaction, [Company Name] is well-equipped to meet the evolving needs of the market and set new benchmarks for excellence in the fabrication and manufacturing industry.In conclusion, [Company Name] has emerged as a force to be reckoned with in the fabrication and manufacturing sector, and its 20th anniversary is a testament to its unwavering dedication and success. As the company continues to thrive and expand its horizons, it remains a trusted partner for businesses seeking top-quality solutions in steel fabrication and manufacturing. Congratulations to [Company Name] on this remarkable milestone, and here's to many more years of excellence and achievement.

Top Solutions for Custom Metal Forming Services

Custom metal forming is a manufacturing process where metal is shaped into a desired form using various techniques such as rolling, stamping, bending, and forging. This process is widely used in various industries including automotive, aerospace, and construction.Custom Metal Forming (CMF), a leading company in the metal forming industry, has been at the forefront of providing high-quality metal forming solutions to its clients for over two decades. With state-of-the-art facilities and a team of experienced engineers and technicians, CMF has earned a reputation for delivering precision-engineered metal components that meet the strictest quality standards.The company's commitment to innovation and continuous improvement has allowed it to stay ahead of the competition and become a preferred partner for businesses looking for custom metal forming solutions. CMF's extensive capabilities and expertise in metal forming enable it to produce a wide range of products, from simple components to complex assemblies, all tailored to meet the specific needs of its customers.One of CMF's core strengths lies in its ability to work with a variety of materials, including steel, aluminum, and stainless steel, and deliver products that are not only durable and reliable but also cost-effective. This versatility allows the company to cater to diverse industries and offer custom metal forming solutions that are tailored to each client's unique requirements.In addition to its manufacturing capabilities, CMF also offers a range of value-added services including design assistance, prototype development, and assembly services. This comprehensive approach allows the company to be a one-stop shop for its clients, providing them with end-to-end solutions for their metal forming needs.In line with its commitment to quality and customer satisfaction, CMF has implemented strict quality control measures throughout its manufacturing process. From raw material inspection to final product testing, the company ensures that each component meets the highest standards of quality and performance.Furthermore, CMF is dedicated to sustainability and environmental responsibility, and it has implemented eco-friendly practices in its manufacturing processes to minimize its carbon footprint and reduce waste. This commitment to sustainability has not only allowed the company to contribute to a greener planet but also to meet the increasing demand for environmentally-friendly products from its customers.As part of its continuous growth and expansion strategy, CMF has recently invested in the latest technology and equipment to further enhance its manufacturing capabilities. This investment has enabled the company to increase its production capacity and efficiency, allowing it to better serve its growing customer base and take on more complex and larger-scale projects.With an unwavering commitment to excellence and a track record of delivering superior metal forming solutions, CMF is poised for continued success and growth in the industry. The company's dedication to innovation, quality, and customer satisfaction has positioned it as a leader in the custom metal forming sector, and it is well-equipped to meet the evolving needs of the market.In conclusion, Custom Metal Forming is a company that stands out in the metal forming industry due to its extensive capabilities, commitment to quality, and customer-centric approach. With a strong focus on innovation and continuous improvement, the company has established itself as a trusted partner for businesses seeking top-notch custom metal forming solutions. As it continues to invest in technology and expand its capabilities, CMF is well-positioned to maintain its leadership position and continue to provide exceptional metal forming solutions to its clients for years to come.

Benefits of Using Laser Technology for Stainless Steel Applications

Laser Stainless Steel, a leading manufacturer of stainless steel products, has been making waves in the industry with its innovative and high-quality offerings. Founded in 2005, Laser Stainless Steel has quickly become a trusted name in the stainless steel manufacturing sector, producing a wide range of products for various industries.The company's state-of-the-art manufacturing facilities and cutting-edge technology have set it apart from its competitors. Laser Stainless Steel's dedication to quality and precision has made it a preferred supplier for many businesses around the world.One of the key factors contributing to Laser Stainless Steel's success is its commitment to innovation. The company is constantly investing in research and development to improve its products and processes. This dedication to innovation has allowed Laser Stainless Steel to stay ahead of the curve and adapt to the ever-changing needs of the industry.Laser Stainless Steel offers a comprehensive range of stainless steel products, including sheets, coils, plates, pipes, tubes, and fittings. The company's products are known for their durability, corrosion resistance, and aesthetic appeal, making them ideal for a wide range of applications.In addition to its standard product offerings, Laser Stainless Steel also provides custom solutions for clients with specific requirements. The company's team of experienced engineers and designers work closely with clients to develop tailor-made products that meet their exact specifications. This personalized approach has earned Laser Stainless Steel a reputation for delivering bespoke solutions that exceed customer expectations.Laser Stainless Steel's dedication to quality is reflected in its adherence to international standards and certifications. The company holds ISO 9001 certification, ensuring that its products meet the highest quality standards. This commitment to quality assurance has earned Laser Stainless Steel the trust and confidence of its customers, who rely on the company's products for their critical applications.In addition to its focus on quality and innovation, Laser Stainless Steel prioritizes sustainability in its operations. The company is committed to environmentally friendly manufacturing practices, minimizing its impact on the planet. Laser Stainless Steel's sustainable approach has resonated with environmentally conscious clients who seek eco-friendly solutions for their projects.Laser Stainless Steel's strong commitment to customer satisfaction sets it apart from its competitors. The company places a high priority on building long-term relationships with its clients, working closely with them to understand their needs and deliver solutions that add value to their businesses. This customer-centric approach has resulted in a loyal customer base that continues to rely on Laser Stainless Steel for their stainless steel requirements.As a global leader in stainless steel manufacturing, Laser Stainless Steel serves a diverse range of industries, including construction, automotive, aerospace, healthcare, and more. The company's products are trusted by clients around the world for their quality, reliability, and performance.Looking ahead, Laser Stainless Steel is focused on expanding its product portfolio and strengthening its position as a market leader in stainless steel manufacturing. The company continues to invest in research and development, exploring new technologies and materials to develop innovative solutions for its clients.In conclusion, Laser Stainless Steel's dedication to quality, innovation, sustainability, and customer satisfaction has solidified its position as a leading manufacturer of stainless steel products. With a strong track record of delivering high-quality solutions for diverse industries, Laser Stainless Steel is poised for continued success and growth in the global market.

Welding Techniques for Joining Stainless Steel and Mild Steel - Available for Sale in China

Welding stainless steel and mild steel together is a challenging task. It requires expertise, precision and high-quality equipment. The process involves joining two materials with different chemical and mechanical properties, which can lead to cracking, distortion and other issues if not done correctly. In this blog, we will explore the process of welding mild steel to stainless steel and some of the challenges that come with it.First, let's look at the materials themselves. Stainless steel has a high chromium content, which makes it resistant to corrosion and stains. It is also harder and more brittle than mild steel, which is why it is challenging to weld the two materials together. Mild steel, on the other hand, has a lower carbon content, making it more ductile and easier to work with when compared to stainless steel.When welding stainless steel to mild steel, there are several methods to consider. Let's take a closer look at some of the most popular welding techniques.1. TIG (Tungsten Inert Gas) Welding: This is one of the most popular welding techniques used in welding stainless steel to mild steel. It provides a precise, clean and high-quality weld, making it ideal for applications that require a high degree of accuracy.2. MIG (Metal Inert Gas) Welding: This is a more straightforward technique compared to TIG welding. It is faster, easier to learn and produces a durable weld. However, the quality of the weld is lower than TIG welding, which may not be suitable for high-end applications.3. Stick Welding: This is a versatile welding method that can be used to weld different materials. It produces a rugged and robust weld that can withstand high temperatures, making it ideal for industrial applications.Regardless of the welding technique used, welding stainless steel to mild steel requires proper preparation. The surface must be clean, free of rust, oil and other contaminants that can affect the quality of the weld. Additionally, the two metals must be preheated to ensure that the thermal stresses are minimized during the welding process.One of the biggest challenges when welding stainless steel to mild steel is the difference in melting points. Stainless steel has a much higher melting point than mild steel, which means that it can easily warp or crack if the welder is not careful. Hence, it is crucial to use specialized welding techniques and equipment to ensure that the two materials are welded together properly without cracking or distortion.In conclusion, welding stainless steel to mild steel can be a daunting task, but it is possible with the right skills, tools, and techniques. With proper preparation and welding processes, it is possible to achieve a strong and durable weld between the two materials. If you need more information on welding stainless steel to mild steel or other welding-related topics, please feel free to reach out to our team of experts.

Laser Cutting of Galvanized Steel: A Key Process for Precision Fabrication

Laser Cutting Galvanized Steel for Superior Precision and EfficiencyIn the world of metal fabrication and manufacturing, precision and efficiency are key factors in ensuring high-quality end products. This is particularly true for galvanized steel, which requires accurate cutting to maintain its protective layer and structural integrity. In light of this, {Company Name} is proud to announce the implementation of state-of-the-art laser cutting technology for galvanized steel.With over 20 years of experience in the industry, {Company Name} has established itself as a leading provider of metal fabrication and manufacturing services. Specializing in a wide range of materials, including stainless steel, aluminum, and galvanized steel, the company is committed to delivering superior products that meet the highest standards of quality and precision.The introduction of laser cutting technology for galvanized steel represents a significant advancement for {Company Name}. This cutting-edge technology allows for unparalleled precision and accuracy, enabling the company to produce intricate and complex designs with ease. In addition, laser cutting is known for its exceptional efficiency, reducing production times and optimizing the use of materials.One of the key advantages of laser cutting galvanized steel is the ability to maintain the integrity of the zinc coating. Galvanized steel is coated with a layer of zinc to protect it from corrosion, and traditional cutting methods can often damage or compromise this protective layer. However, laser cutting is a non-contact process, meaning that there is no physical force acting on the material. As a result, the zinc coating remains intact, preserving the corrosion-resistant properties of the steel.Furthermore, laser cutting offers a level of precision that is unmatched by traditional cutting methods. The focused beam of the laser can achieve incredibly fine and intricate cuts, allowing for the creation of complex designs and shapes with minimal margin for error. This level of precision is particularly crucial in industries such as automotive, construction, and engineering, where the highest standards of accuracy are required.In addition to its precision, laser cutting also offers exceptional efficiency and cost-effectiveness. The speed and accuracy of the process result in reduced production times, which can ultimately lead to cost savings for {Company Name} and its clients. Furthermore, the minimal waste generated during laser cutting means that materials are used more effectively, contributing to a more sustainable and environmentally friendly manufacturing process.{Company Name} understands the importance of staying at the forefront of technological advancements in the industry, and the adoption of laser cutting for galvanized steel is a testament to this commitment. By investing in the latest equipment and machinery, the company continues to offer innovative solutions that meet the evolving needs of its customers.In conclusion, the introduction of laser cutting technology for galvanized steel is a significant development for {Company Name}. This cutting-edge technology enables the company to achieve unprecedented levels of precision, efficiency, and quality in the fabrication of galvanized steel products. With its extensive experience and dedication to excellence, {Company Name} is well-positioned to lead the way in providing superior metal fabrication and manufacturing services for a wide range of industries.

Welding Cast Steel to Mild Steel: How to Seamlessly Join Different Metals

Welding Cast Steel To Mild SteelWelding is a crucial process in the manufacturing industry, and it requires precision and expertise to ensure the quality and durability of the final product. One of the most common welding processes is joining cast steel to mild steel, a technique that requires skill and the right equipment to achieve a strong and reliable bond.{} is a leading company in the welding industry, specializing in providing high-quality welding equipment and solutions for various applications. With a strong focus on innovation and customer satisfaction, {} has been at the forefront of developing advanced welding technologies that meet the needs of modern industries.When it comes to welding cast steel to mild steel, {} has proven to be a trusted partner for many manufacturing companies. With a wide range of welding equipment and consumables, {} offers the right tools and expertise to achieve a successful weld between cast steel and mild steel.The process of welding cast steel to mild steel requires careful preparation and execution to ensure a strong and durable bond. {} provides a comprehensive range of welding consumables, including electrodes, wires, and fluxes, specially designed for welding cast steel to mild steel. These consumables are manufactured to the highest standards, ensuring the integrity of the weld and the quality of the final product.In addition to providing high-quality consumables, {} also offers a range of welding equipment designed for joining cast steel to mild steel. From advanced welding machines to cutting-edge welding torches and accessories, {} provides the necessary tools for achieving a precise and reliable weld.One of the key challenges in welding cast steel to mild steel is the difference in the composition and properties of the two materials. Cast steel is known for its high strength and resistance to wear, while mild steel is more ductile and easier to weld. {} understands the unique characteristics of both materials and offers specialized welding solutions to overcome the challenges of joining them together.With a team of experienced technicians and engineers, {} also provides technical support and expertise to help customers optimize their welding processes. From selecting the right consumables to fine-tuning welding parameters, {} works closely with its customers to ensure a successful weld between cast steel and mild steel.In addition to its expertise in welding technology, {} is also committed to innovation and continuous improvement. The company invests in research and development to advance the capabilities of its welding equipment and consumables, ensuring that customers have access to the latest technologies for welding cast steel to mild steel.Furthermore, {} is dedicated to providing comprehensive training and support to its customers, empowering them with the knowledge and skills to achieve high-quality welds. Through its training programs and technical workshops, {} equips welding professionals with the expertise they need to master the process of joining cast steel to mild steel.As a trusted partner in the welding industry, {} has built a reputation for delivering reliable solutions and exceptional customer service. The company's commitment to quality and innovation has established {} as a preferred supplier for welding equipment and consumables, particularly for challenging applications such as welding cast steel to mild steel.In conclusion, welding cast steel to mild steel is a critical process that requires precision, expertise, and the right equipment. With its comprehensive range of welding solutions and technical support, {} has emerged as a leading provider of high-quality welding technology for joining cast steel to mild steel. As manufacturing industries continue to evolve, {} remains dedicated to supporting its customers with advanced welding solutions that meet their specific needs and challenges.

Sheet Metal Cutting Service for Precision and Efficiency

Sheet Metal Cutting Service Advances in Precision and Efficiency[City, Date] - Sheet metal fabrication has come a long way in recent years with the help of advanced technologies and innovative cutting services. One such company leading the charge is revolutionizing the industry with their state-of-the-art sheet metal cutting service.Sheet metal cutting is a crucial aspect of the fabrication process, as it determines the accuracy and precision of the final product. With the company's cutting-edge technology and skilled workforce, they have been able to consistently deliver exceptional results.The cutting service offered by the company utilizes advanced machinery, including CNC (Computer Numerical Control) laser cutting and plasma cutting equipment. These cutting-edge technologies have revolutionized the sheet metal fabrication industry, allowing for faster production times and improved precision.With CNC laser cutting, the company is able to achieve intricate designs and complex shapes with absolute precision. This advanced process involves a high-powered laser beam focused onto the material, which melts, burns, or vaporizes the excess material. The result is a clean and precise cut, ensuring that the final product meets the customer's exact specifications.Plasma cutting, on the other hand, is a versatile method ideal for cutting various types of metal. By using a high-velocity jet of ionized gas, this process melts and blows away the excess material, leaving behind a smooth and precise cut. With the ability to cut through thick materials, plasma cutting allows for quick and efficient production, saving both time and costs.The company's cutting service is not limited to a specific industry or application. They have successfully provided cutting solutions for a wide range of sectors, including automotive, aerospace, electronics, architecture, and more. From custom prototypes to large-scale production, their cutting service caters to diverse customer needs.Moreover, the company's cutting service is complemented by their team of skilled technicians and engineers. These professionals have extensive knowledge and expertise in sheet metal fabrication, ensuring that every project is carried out with utmost precision and attention to detail. Their commitment to quality is reflected in the final products they deliver.In addition to their cutting service, the company also offers value-added services such as welding, bending, and finishing. This comprehensive approach allows customers to streamline their manufacturing process by availing multiple services under one roof. It also ensures consistent quality and timely delivery, eliminating the need for outsourcing and reducing production costs.To further enhance customer satisfaction, the company has implemented a responsive customer support system. Their team of knowledgeable customer service representatives is readily available to assist clients with their inquiries, provide technical support, and offer advice on optimizing their sheet metal cutting requirements.In conclusion, sheet metal cutting has reached new levels of precision and efficiency with the help of advanced technologies and innovative services. With their cutting-edge machinery, skilled workforce, and commitment to quality, the company is at the forefront of the industry. Their sheet metal cutting service caters to diverse industries, delivering precise cuts for a variety of applications. With the added value of value-added services and responsive customer support, customers can rely on the company to meet their sheet metal fabrication needs efficiently and effectively.

High-Quality Laser Cutting Sheet Services for Precision Fabrication

Laser Cutting Sheet, one of the most innovative and advanced technologies in the manufacturing industry, has revolutionized the way companies create intricate and precise designs on various materials. This cutting-edge technique has become increasingly popular due to its ability to cut through a wide range of materials with high precision and speed. From metal to plastic, wood to glass, laser cutting has become the go-to method for creating detailed and high-quality products.At the forefront of this innovative technology is the leading manufacturing company {}. Specializing in custom metal fabrication, the company has been dedicated to providing top-notch products and services to a wide range of industries. With the integration of laser cutting sheet technology into their manufacturing processes, they have been able to push the boundaries of what is possible in the realm of metal fabrication.Laser cutting sheet technology utilizes a high-powered laser to precisely cut through materials with extreme accuracy. This allows for intricate designs to be created with a level of detail that was previously impossible to achieve. The precision of laser cutting sheet technology also ensures that there is minimal material wastage, making it a cost-effective and environmentally friendly solution for manufacturing.The team at {} has fully embraced this cutting-edge technology and has incorporated it into their production processes. With state-of-the-art laser cutting equipment, they are able to offer their clients a wide range of custom metal fabrication services. Whether it's intricate metal wall art, precision-cut metal components for machinery, or decorative metal signage, {} has the capabilities to bring their clients' visions to life with precision and accuracy.One of the key advantages of laser cutting sheet technology is its ability to cut through a variety of materials, including stainless steel, aluminum, copper, brass, and more. This versatility allows {} to cater to the needs of clients from a diverse range of industries, including automotive, aerospace, architecture, and interior design. The ability to work with a wide range of materials sets {} apart as a leader in the metal fabrication industry.Furthermore, the speed and accuracy of laser cutting sheet technology have significantly reduced production lead times for {} clients. This means that even the most complex and detailed projects can be completed in a fraction of the time compared to traditional cutting methods. This not only benefits clients in terms of project timelines but also allows for a faster turnaround and increased productivity for {}.The team at {} prides itself on its commitment to quality and precision, and the integration of laser cutting sheet technology has only enhanced their ability to deliver exceptional products to their clients. With a focus on continuous improvement and innovation, they are constantly pushing the boundaries of what is possible in the world of custom metal fabrication.In conclusion, laser cutting sheet technology has become an integral part of the manufacturing process at {}. With its ability to cut through a wide range of materials with precision and speed, this innovative technology has allowed {} to elevate the quality of their products and services. As a leader in the metal fabrication industry, {} is dedicated to staying at the forefront of technological advancements and providing their clients with the highest quality custom metal fabrication solutions.